Hand protecting fence for stamping apparatus

A technology for hand protection and stamping equipment, applied in the stamping field, can solve the problems of aging and failure of components and difficult to detect, and achieve the effects of low production cost, avoidance of work-related injuries and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

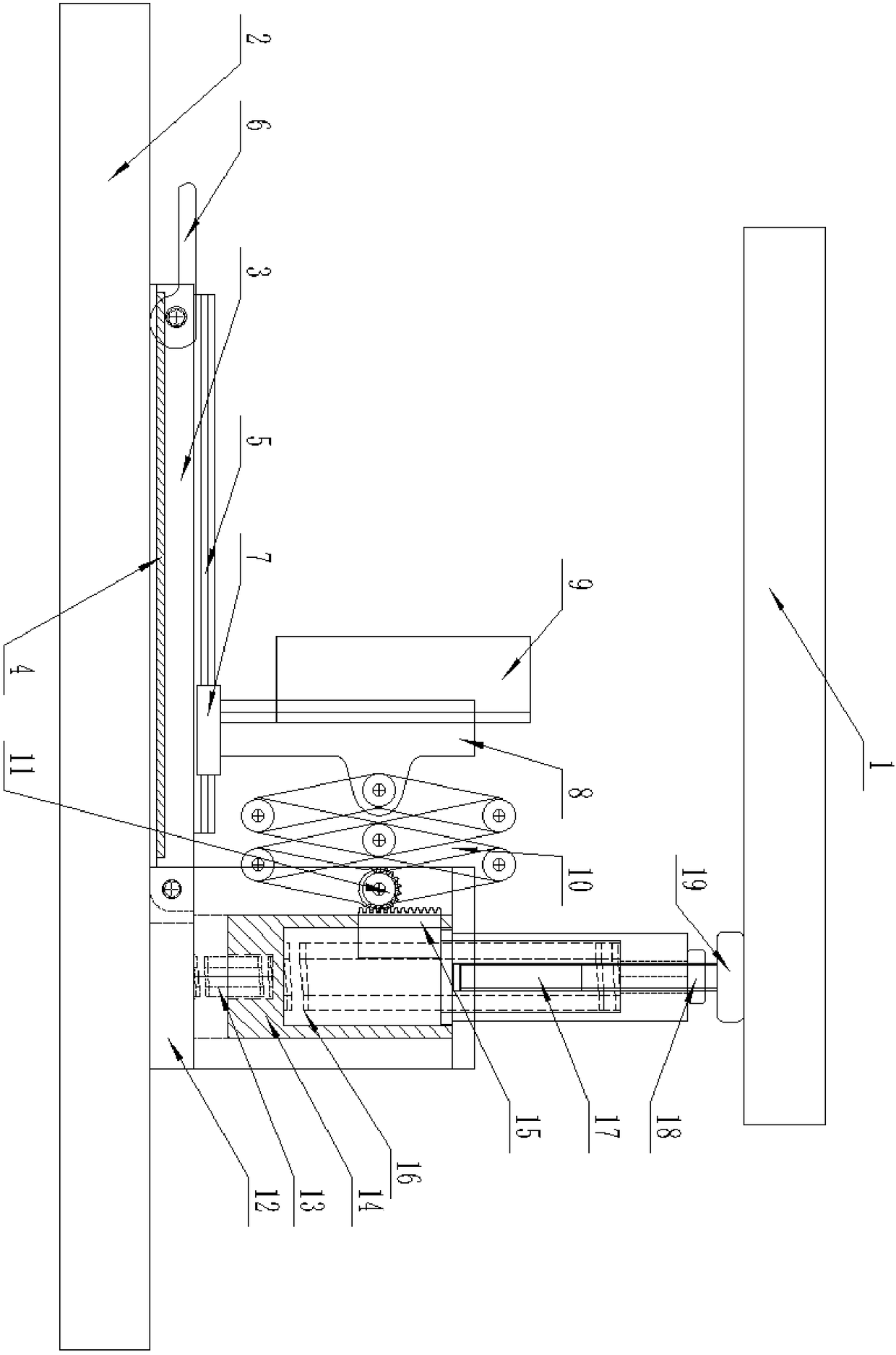

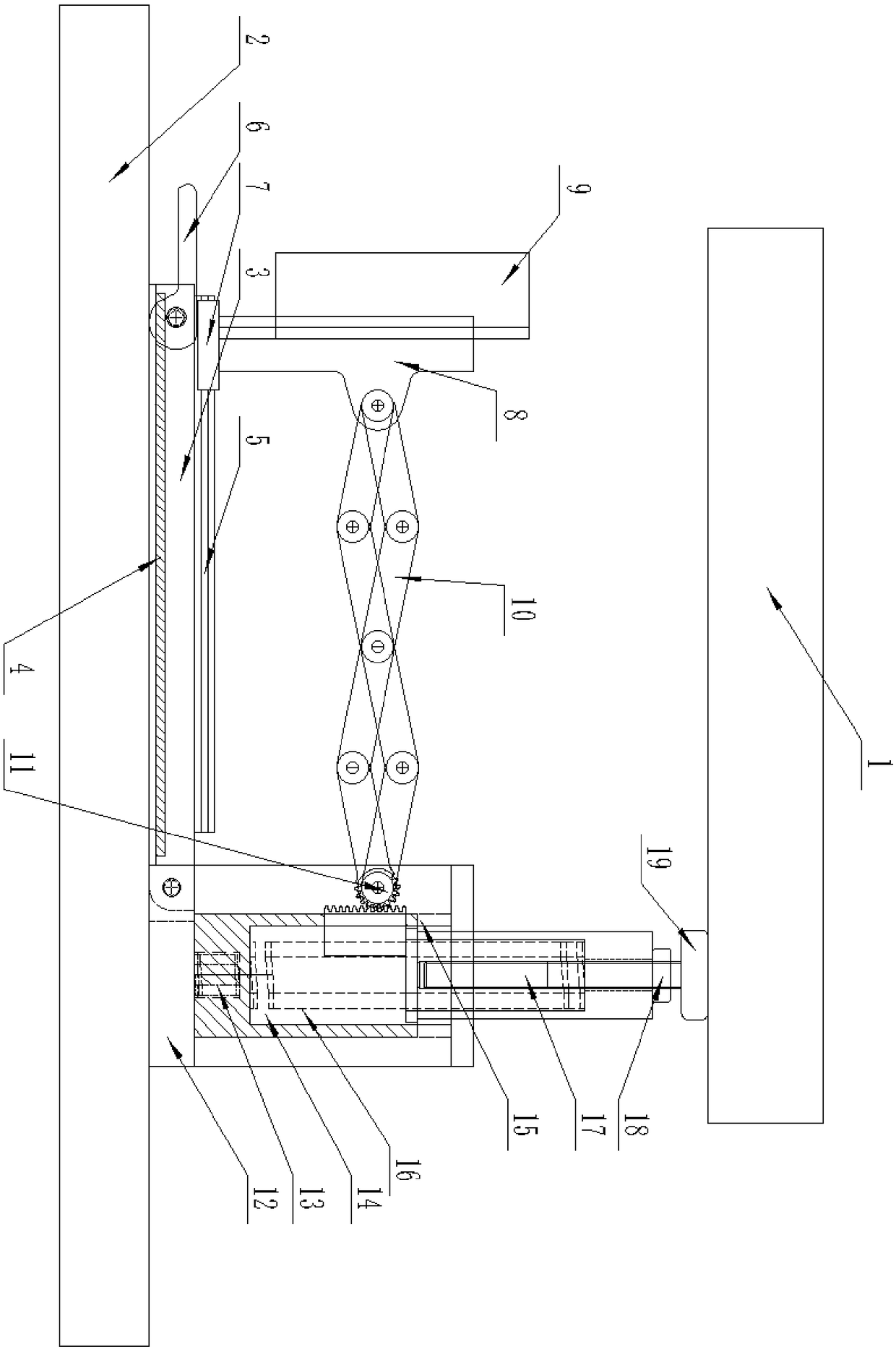

[0013] Such as figure 1 with figure 2 As shown, this specific embodiment adopts the following technical solutions: a hand protection bar for stamping equipment, including a sliding seat 1 on the punching machine and a lower working surface 2 on the punching machine, the sliding seat 1 on the punching machine is located above the lower working surface 2 of the punching machine, Also includes base 3, powerful magnet 4, slide rail 5, disassembly handle 6, slider 7, slide plate 8, push hand plate 9, telescopic arm 10, gear 11, recessed seat 12, small spring 13, movable block 14, rack 15. Large spring 16, bolt 17, adjusting nut 18 and support seat 19; the lower surface of the base 3 is fixedly connected with a powerful magnet 4; the base 3 is fixedly connected to the upper surface of the lower working table 2 of the punch press through the powerful magnet 4 The left side of the upper surface of the lower working table 2 of the punch press is fixedly connected with a concave word ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com