Automatic wood board paper pasting equipment

A wood board, automatic technology, applied in the direction of wood processing appliances, manufacturing tools, adhesive application devices, etc., can solve the problems of inconvenient use, time-consuming and laborious, and achieve the effects of improving production efficiency, uniform gluing, and convenient use and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

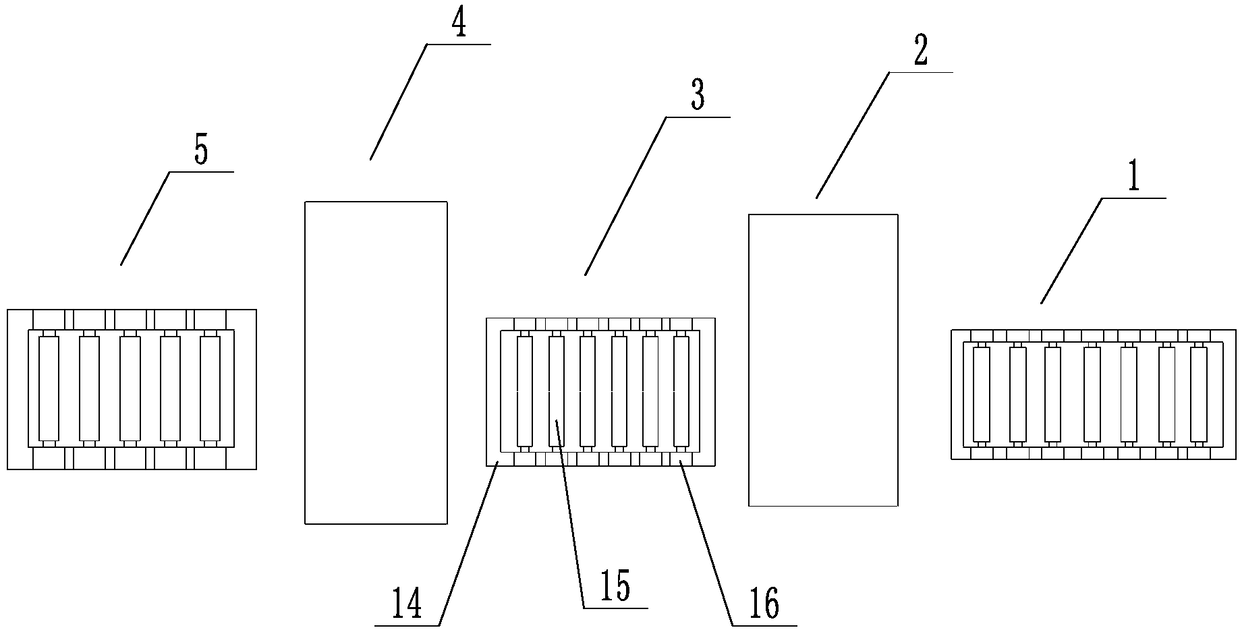

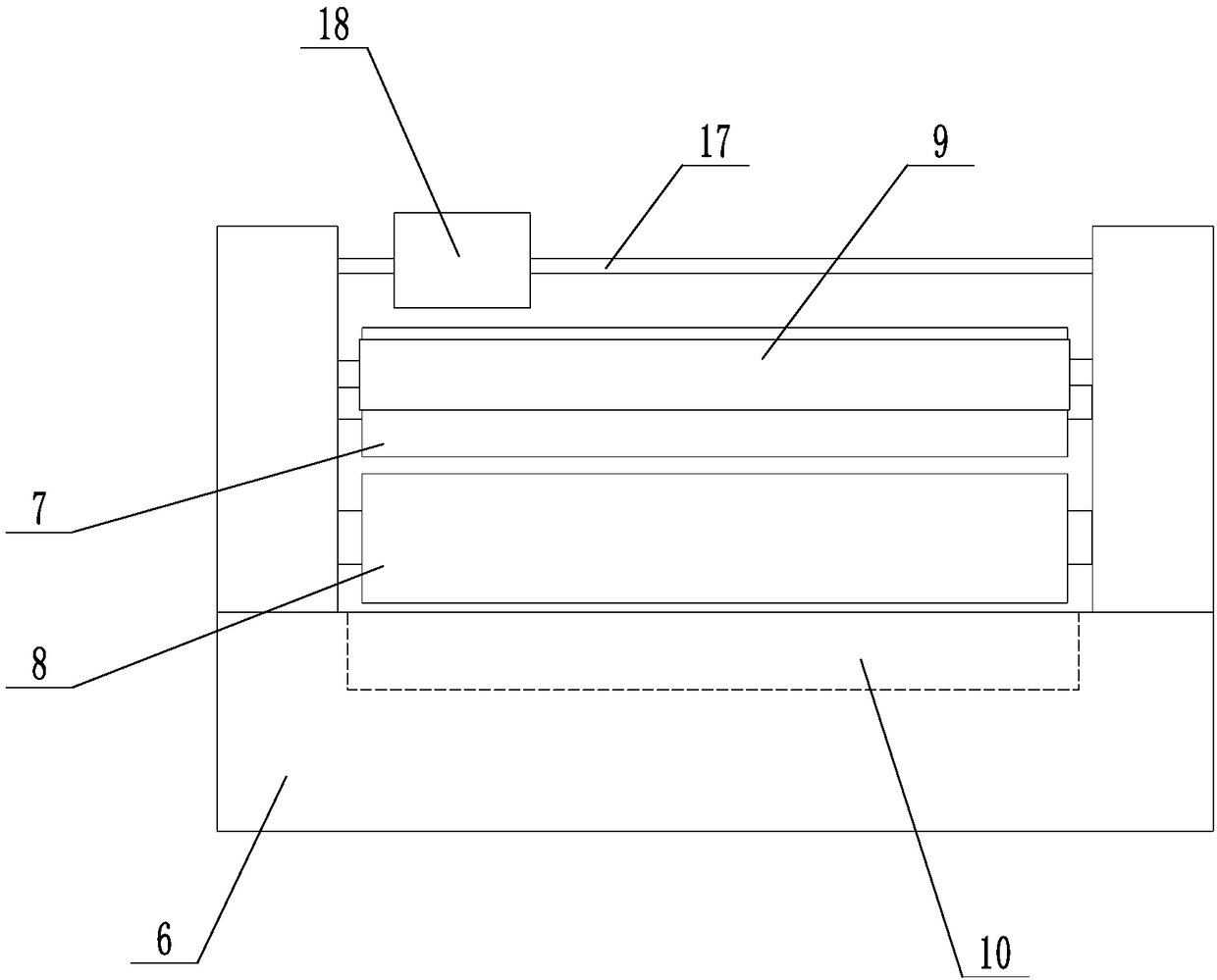

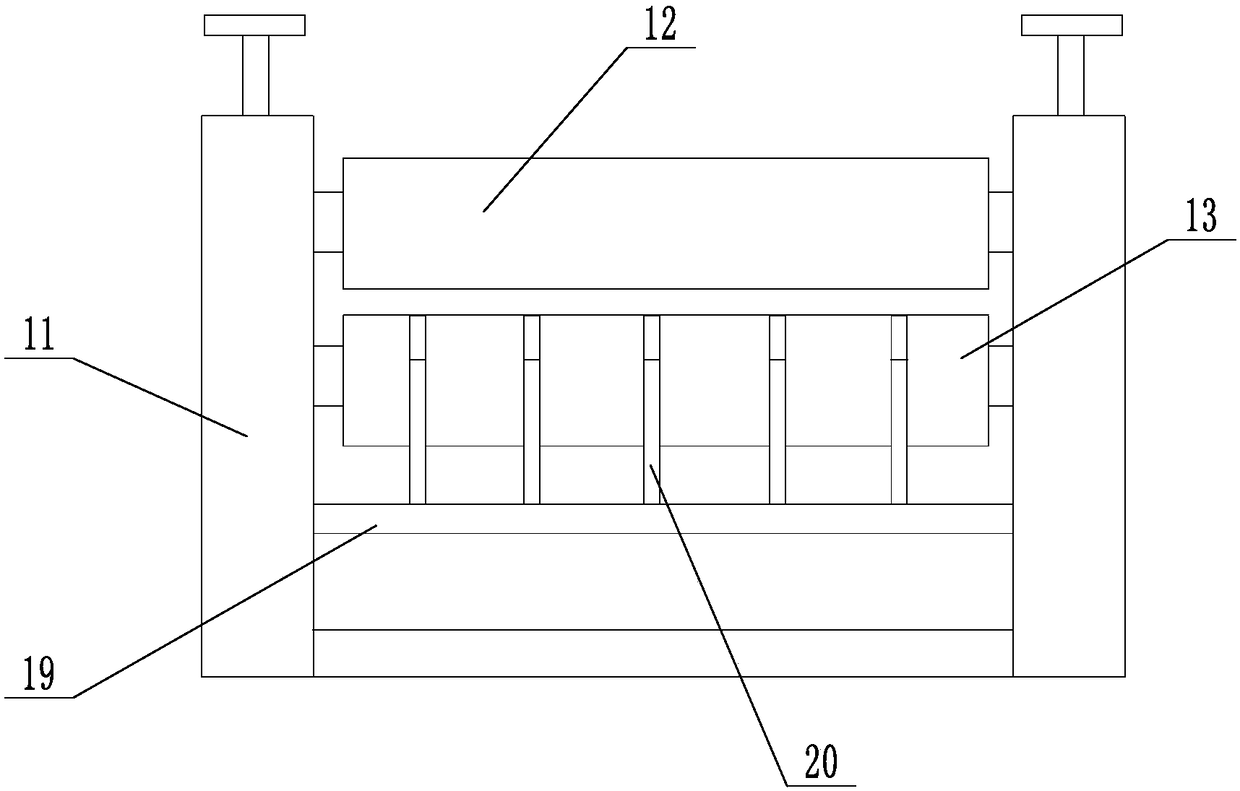

[0018] like Figure 1 to Figure 4 As shown, a kind of wooden board automatic sticker equipment, comprises the first conveying platform 1 that is arranged successively along the conveying direction of wooden board, gluing device 2, the second conveying platform 3, pressing device 4 and the 3rd conveying platform 5, described coating The gluing device 2 comprises a first machine base 6, on the first machine base 6, a glue-coating roller is rotatably arranged, and the glue-coating roller comprises a horizontally arranged upper glue-coating roller 7 and a lower glue-coating roller 8, and the upper glue-coating roller 7 passes through the first Driven by a driving device, the side of the upper glue roller 7 is provided with a scraping roller 9, and the bottom of the upper glue roller 7 is provided with a glue tank 10. The pressing device 4 includes a second base 11, on which the second base 11 The rotatable level is provided with an upper pressure roller 12 and a lower pressure rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com