Self-compacting concrete and its preparation technology

A self-compacting concrete and mixer technology, applied in the field of concrete, can solve the problems of large amount of cementitious materials, high cement consumption, and high cost of self-compacting concrete, and achieve the effects of improving impermeability, saving costs, and smoothing the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

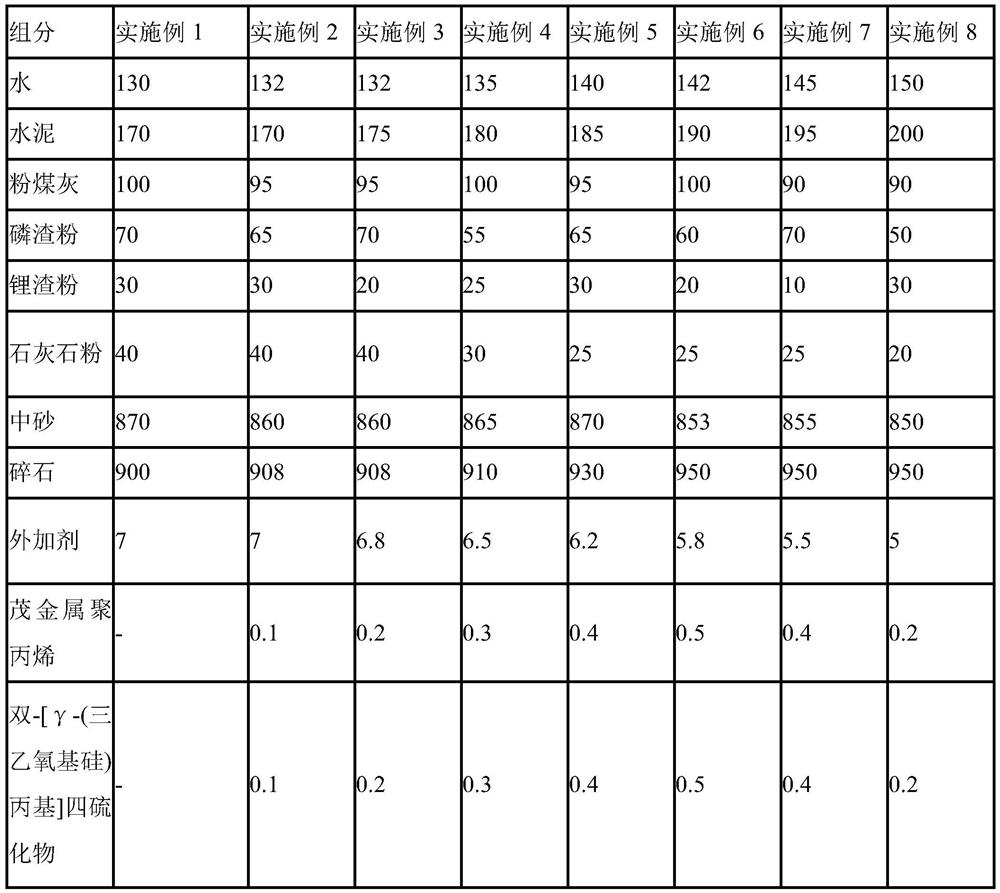

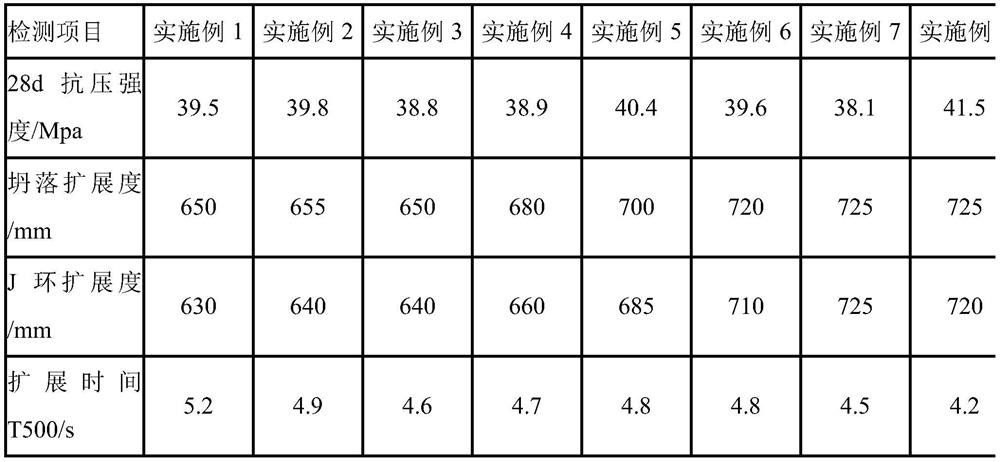

Examples

Embodiment 9

[0051] A preparation process for self-compacting concrete, comprising the following preparation process:

[0052] S1. Pour 10-20 parts of water into the mixer to wet the mixer;

[0053] S2, medium sand and crushed stone are poured into the mixer and mixed evenly;

[0054] S3, add remaining water, stir evenly;

[0055] S4, cement, fly ash, phosphorus slag powder, lithium slag powder, limestone powder, metallocene polypropylene, bis-[γ-(triethoxy silicon) propyl]tetrasulfide and water-reduced polycarboxylic acid The admixture composed of anti-slump agent, slump-retaining agent, early-strength agent, water-retaining agent and air-entraining agent is added to the mixer together, and 2 to 3 parts by weight of dry ice particles are added to the mixer, and stirred evenly;

[0056] S5. Add the defoamer into the blender, stir and mix evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com