A grid cluster and energy-saving cocoon picking machine

A technology of grid cluster and cocoon picking machine, which is applied in animal husbandry and other directions, can solve the problems of inconvenient picking of cocoons and heavy workload of removing silkworm cocoons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

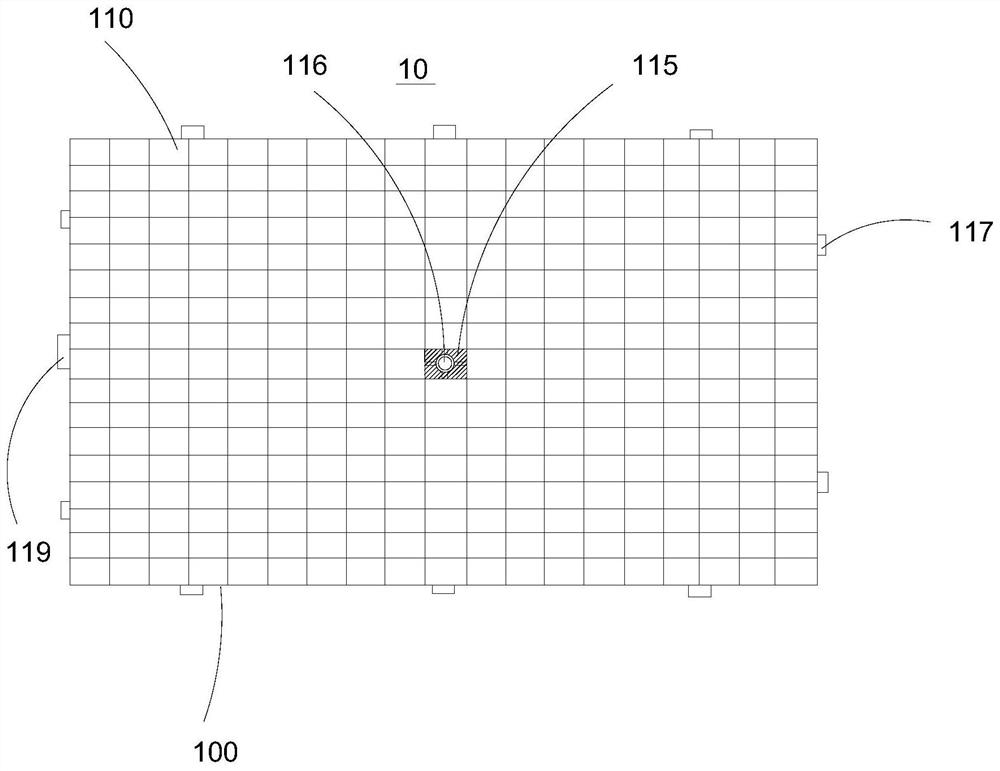

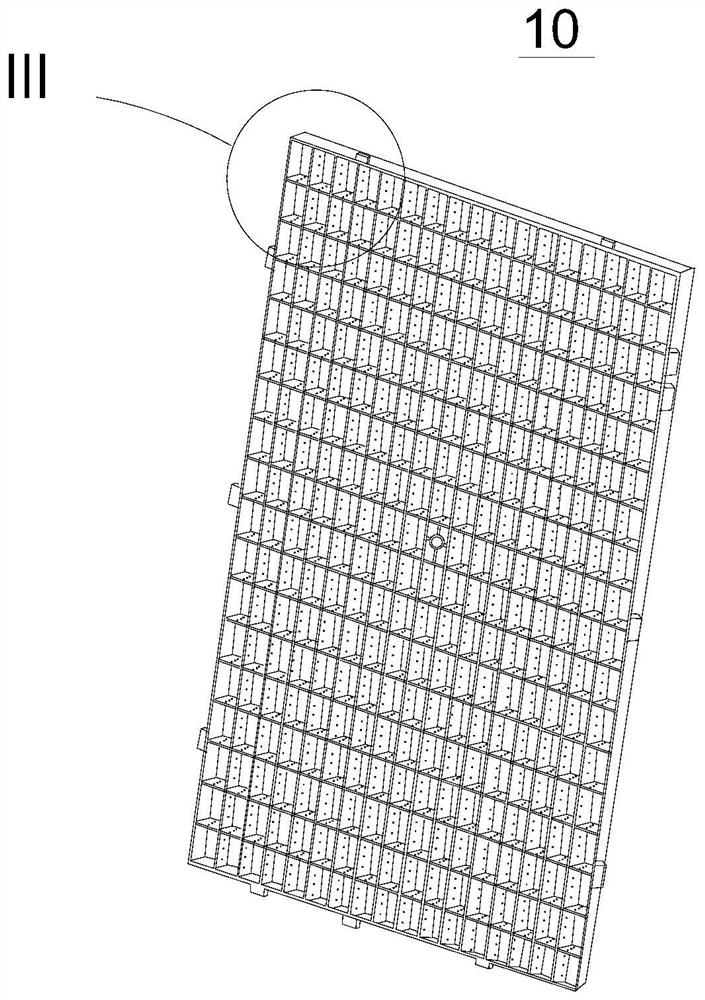

[0030] Please refer to figure 1 as well as figure 2 , this embodiment provides a grid cluster 10 , which includes a grid cluster body 100 .

[0031] Wherein, the grid cluster body 100 is in the shape of a rectangular frame, and the grid cluster body 100 is provided with grids 110 arranged in a rectangular array, wherein, the grids 110 are used for a single cooked silkworm to enter and spin silk therein to form cocoons. for subsequent collection.

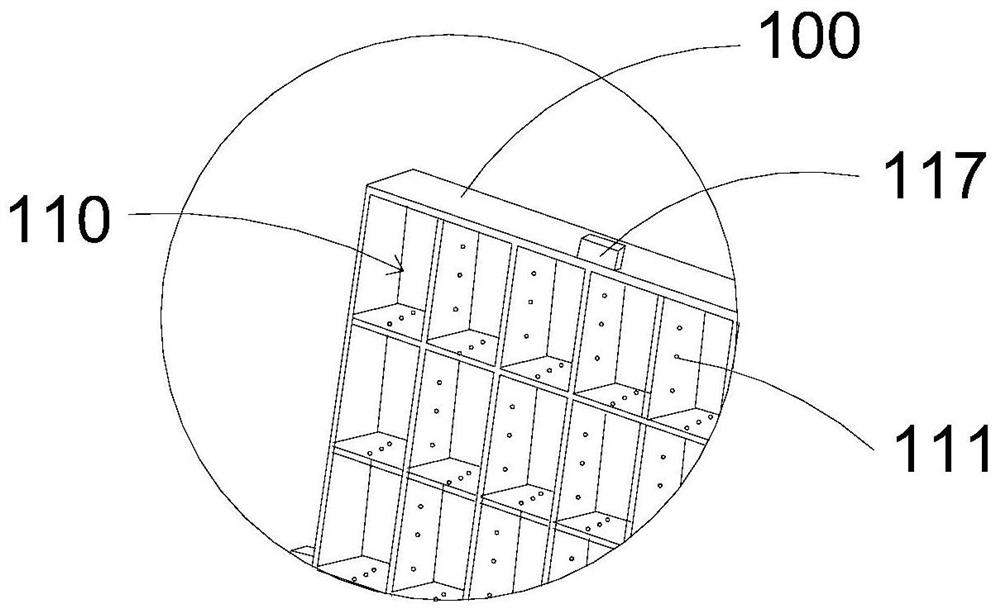

[0032] Because, in the actual production process, in the process of spinning silkworms in the grid 110, in order to make the cooked silkworms climb steadily when they are on the cluster and not fall to the ground to cause silkworm casualties, the silkworms in the grid 110 can also be adjusted at the same time. The horizontal flow of air speeds up the water removal when silkworms spin silk and improves the quality of cocoon unwinding. Please refer to image 3 , preferably any two adjacent squares 110 are connected through the thro...

Embodiment 2

[0043] Please refer to Figure 5 , this embodiment provides an energy-saving cocoon picking machine 20a, which includes a main body 200 and the grid cluster 10 provided in Embodiment 1.

[0044] Wherein, the body 200 is provided with a fixing bracket 210 , a driving mechanism 250 , a grid cluster placement frame 230 , a bottom plate 220 and a bracket 290 .

[0045] Among them, see Figure 5 as well as Figure 7 , the bottom plate 220 includes a first side plate 221, a second side plate 222, a third side plate 223 and a main board 225, the first side plate 221 and the third side plate 223 are arranged on both sides of the length direction of the main board 225, and the second side Two ends of the board 222 are connected to the first side board 221 and the third side board 223 , and top ends of the first side board 221 , the second side board 222 and the third side board 223 are connected to the fixing bracket 210 . That is, an accommodating cavity (not shown) with an opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com