Dust collector and dust retaining device applied to same

A vacuum cleaner and dust blocking technology, which is applied to vacuum cleaner storage devices, vacuum cleaners, applications, etc., can solve the problems of easy dust clogging, unsmooth rotation of dust baffles, holes and shafts that are difficult to disassemble and clean, etc., to achieve the effect of improving the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

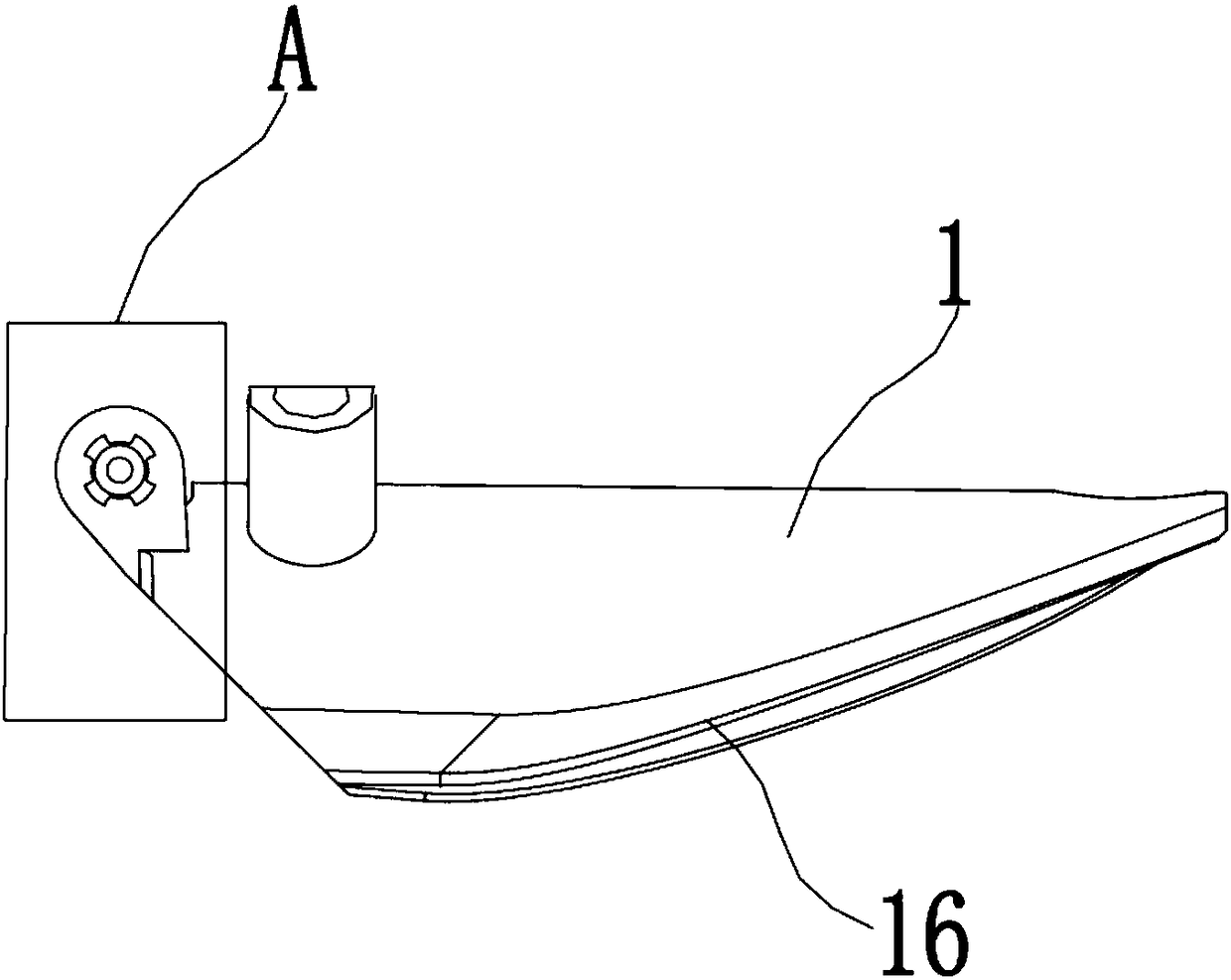

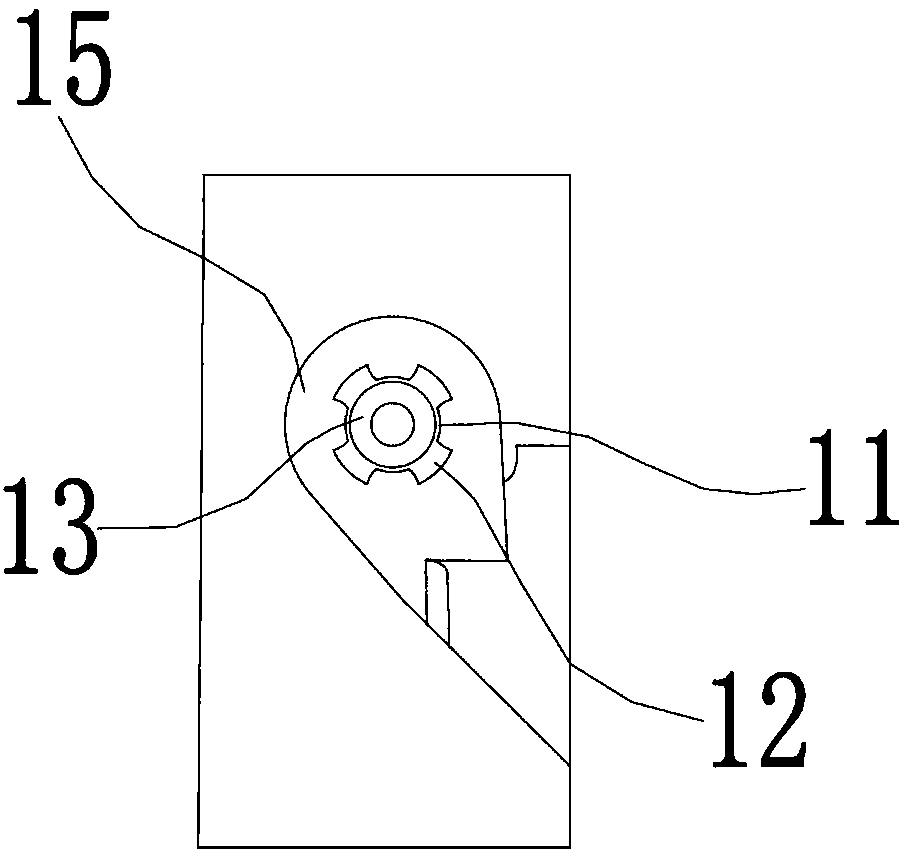

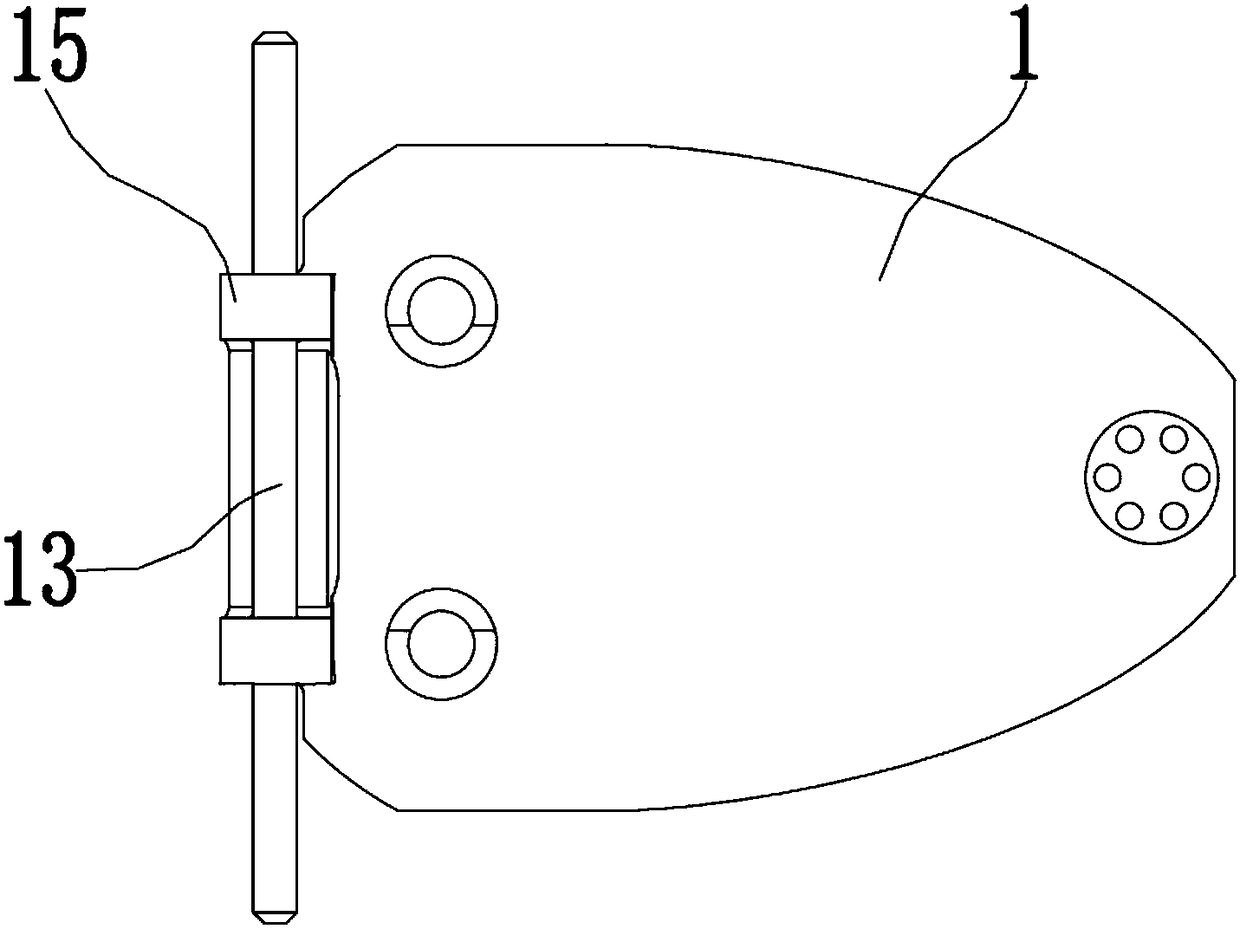

[0026] see Figure 1 to Figure 7 , the figure shows a dust-blocking device applied to a vacuum cleaner provided by an embodiment of the present invention, which includes a dust-blocking part 1, which is a plate with a tapered surface 16 at the bottom, and the dust-blocking part 1 is rotatable Installed at the air inlet 21 of the dust storage part 2, the dust blocking part 1 has a convex strip 15, the assembly hole 11 runs through the convex strip 15 along the axial direction of the convex strip 15, the assembly hole 11 is a round hole, and the assembly hole 11 The inner wall is provided with a plurality of grooves 12, four of which are specifically provided in this embodiment. The plurality of grooves 12 form a spline groove structure. The hole body 22 and the rotating shaft 13 pass through the two hole bodies 22 and the assembly hole 11 at the same time. Wherein, the dust storage component 2 is specifically a dust cup, and may also be a dust bag or the like.

[0027] At the...

Embodiment 2

[0030] Others are the same as those described in the first embodiment, except that only one tank body 12 is selectively provided.

Embodiment 3

[0032] continue to see Figure 1 to Figure 4 , the figure shows a dust blocking device applied to vacuum cleaners provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the assembly hole 11 includes The two hole units 14 are coaxially arranged, and there is an axial gap 141 between the two hole units 14 . Through the setting of the above structure, firstly, the assembly length of the assembly hole and the rotating shaft on the dust-blocking part can be shortened, the contact area between the assembly hole and the rotating shaft is reduced, and the dust is prevented from being blocked here; The setting of the gap enables the dust that is centrifugally fly out to be discharged from the opposite sides of the assembly hole, and the dust discharge efficiency is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com