Brake switch structure

A technology of brake switch and switch head, which is applied to electric switches, brakes, brake components, etc., and can solve problems such as water ingress corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

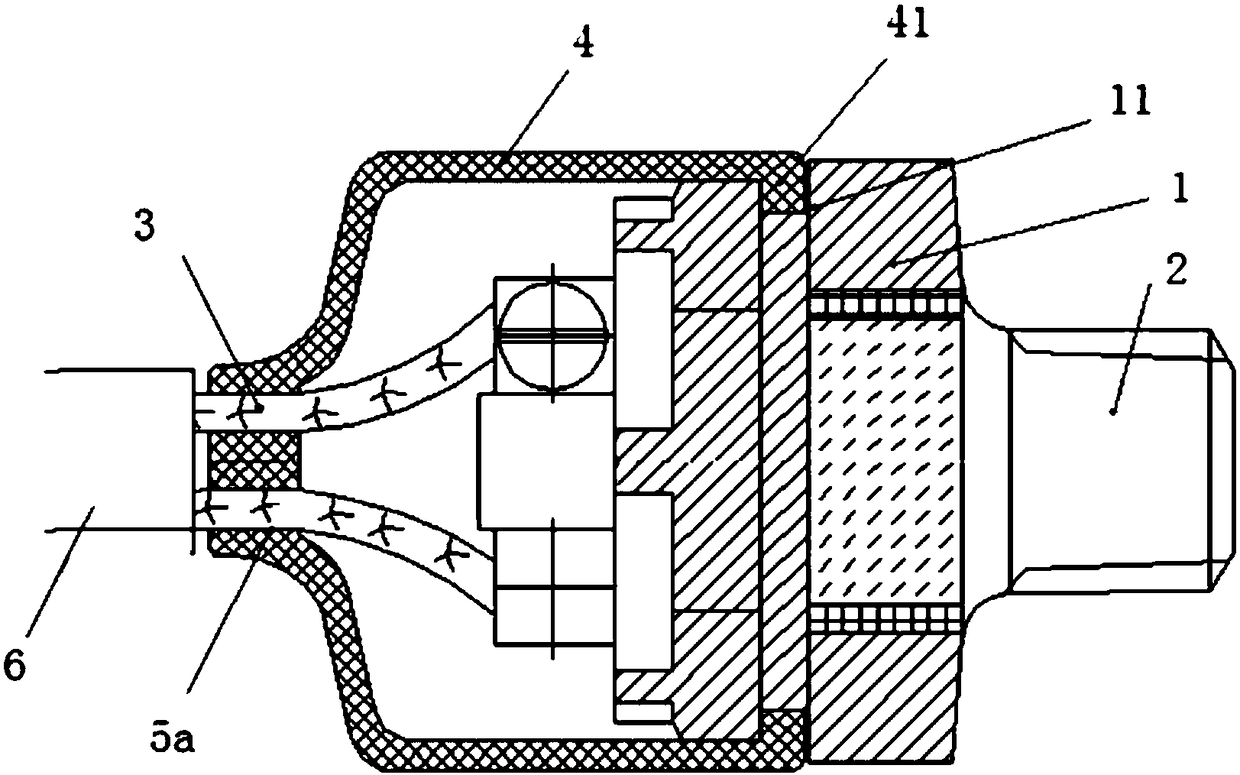

[0023] A brake switch structure, see figure 1 , including: a base 1, a switch head 2, a wire harness 3 and a protective cover 4, one end of the base 1 is a function end, and the other end is a connection end; The protective cover 4 is sleeved on the base 1 to cover the connection end and expose the functional end, so that the switch head 2 is also exposed from the protective cover 4 .

[0024] A through hole 5 a is formed on the protective cover 4 , the wire harness 3 protrudes from the through hole 5 a, and the diameter of the through hole 5 a is smaller than or equal to the outer diameter of the wire harness 3 . Preferably, the protective cover 4 is a rubber member, and the through hole 5a has a certain degree of elasticity, so that it can tighten the wire harness 3, thereby achieving a seal between the through hole 5a and the wire harness 3 to avoid water leakage.

[0025] On the portion between the functional end and the connecting end of the base 1, a circle of connectin...

Embodiment 2

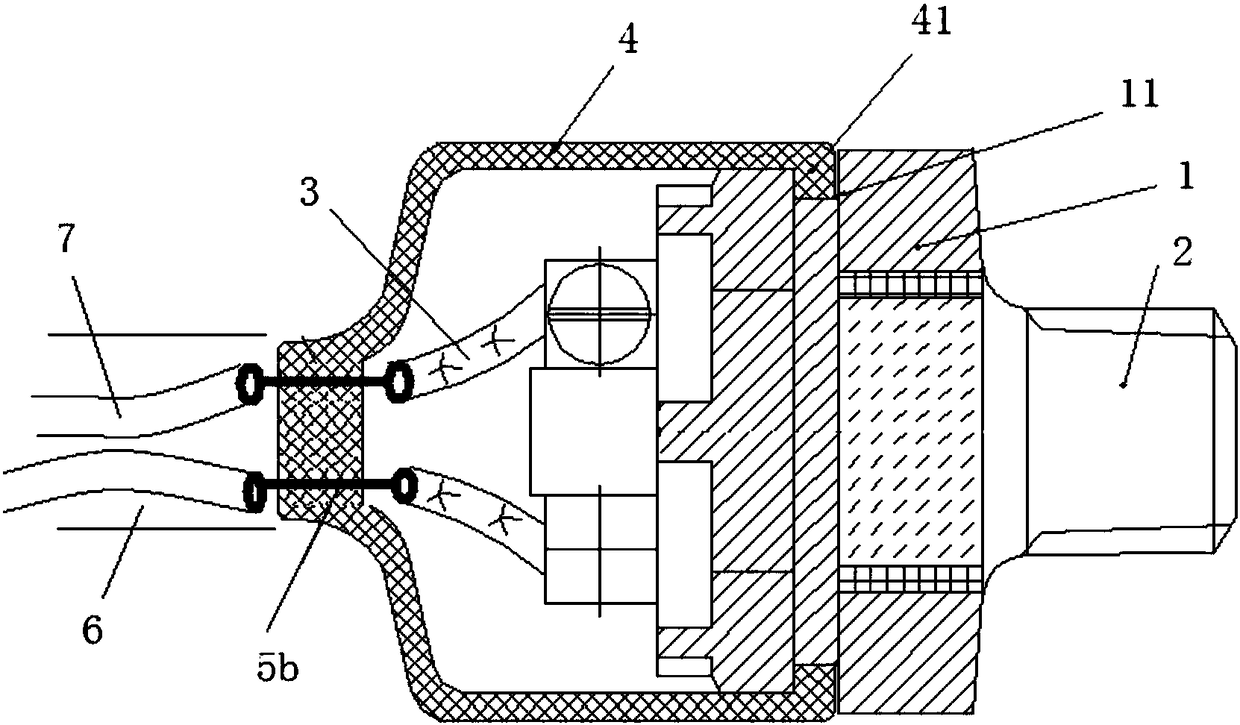

[0029] A brake switch structure, see figure 2 , including: a base 1, a switch head 2, a wire harness 3 and a protective cover 4, one end of the base 1 is a function end, and the other end is a connection end; The protective cover 4 is sleeved on the base 1 to cover the connection end and expose the functional end, so that the switch head 2 is also exposed from the protective cover 4 .

[0030] A connecting terminal 5 b is formed on the protective cover 4 , one end of the connecting terminal 5 b is located inside the protective cover 4 and connected to the wire harness 3 , and the other end of the connecting terminal 5 b protrudes from the protective cover 4 and is connected to the external wire 7 . Preferably, the protective cover 4 is a rubber part. The connection terminal 5b is a conductive structure, and it can be vulcanized with the protective cover 4, or other methods can be used, as long as the connection terminal 5b is guaranteed to be connected inside and outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com