Fan-shaped section transverse tension resisting device of slab continuous casting machine

A transverse tension and slab continuous casting technology, applied in the field of slab continuous casting production, can solve problems such as the relative displacement of the frame position, and achieve the effect of reducing the arc, reducing the influence and avoiding the lateral displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail now in conjunction with accompanying drawing.

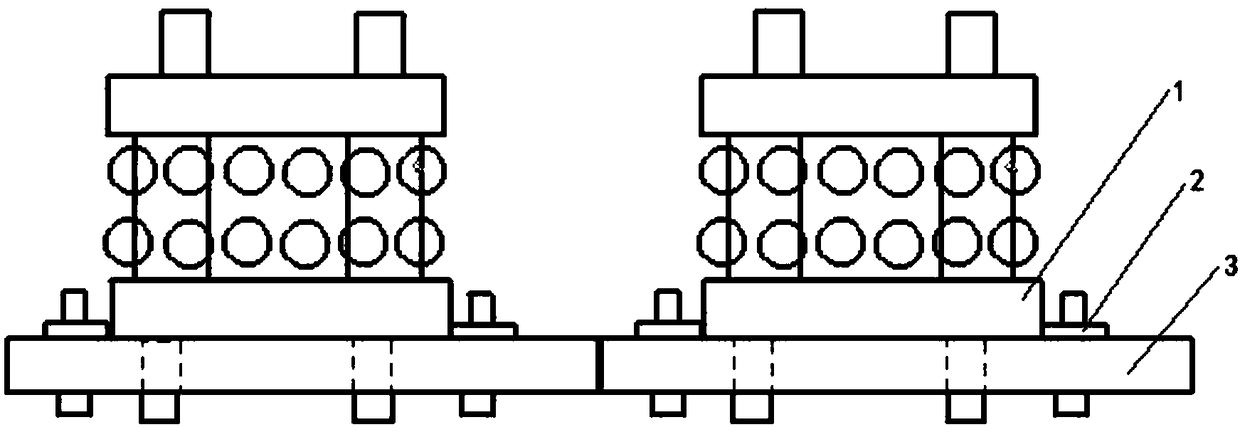

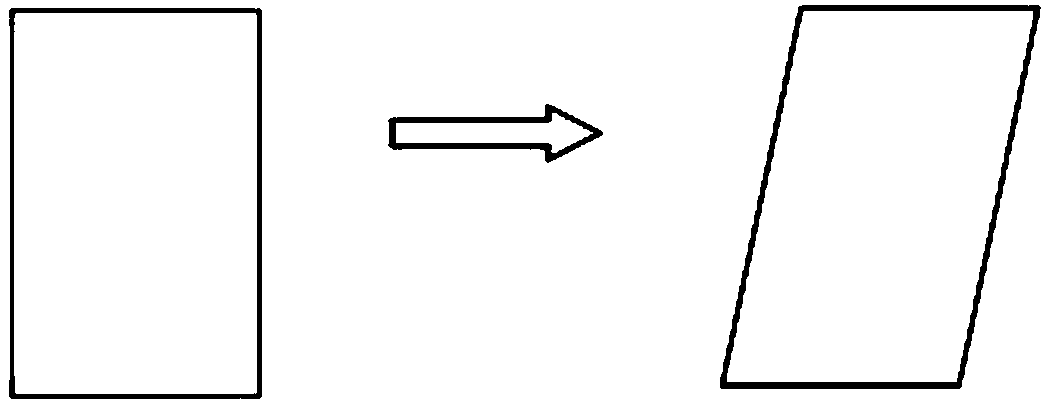

[0017] At present, in the prior art, the sector fixing method mainly fixes the sector frame 1 on the base through fixing bolts 2, such as figure 1 As shown, when the sector frame 1 is subjected to the reaction force of the slab greater than its own bearing force, there will be lateral displacement, as shown in figure 2 As shown, especially in the case of continuous casting opening and capping, the billet head and billet tail, the billet temperature is low when dealing with breakouts, lying billets, etc., it is not easy to straighten, and it will cause greater destructive force to the sector. 2 is loose, and if it is heavy, the fixing bolt 2 will be pulled out and broken.

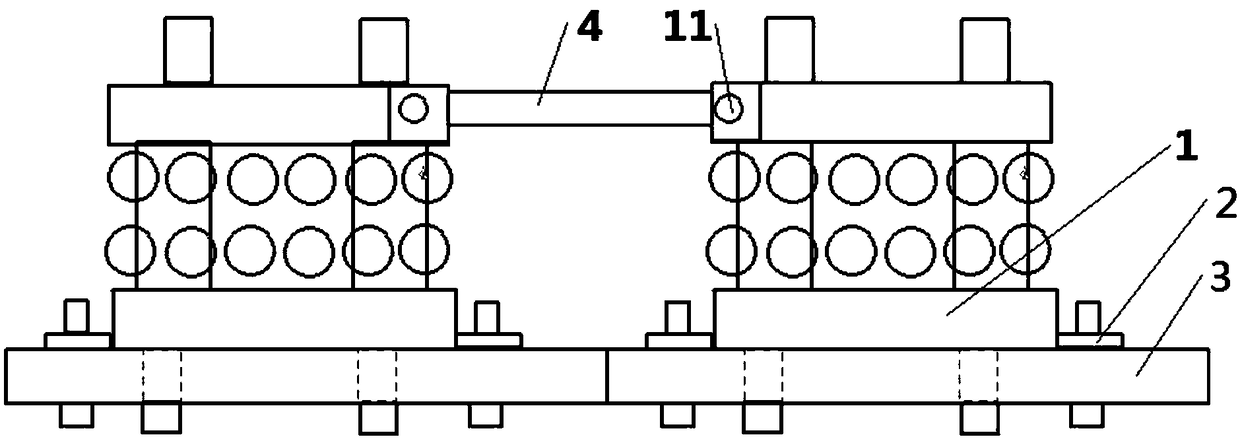

[0018] In order to solve the above problems, the present invention provides a slab continuous casting machine segment anti-transverse tension device, such as image 3 , Figure 4 , Figure 5 As sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com