A fruit automatic screening and packaging machine

A packaging machine and automatic screen technology, applied in packaging, packaging food, packaging protection and other directions, can solve the problems of low efficiency, time-consuming and laborious packaging, large output and transaction volume, etc., to improve efficiency and quality, save labor costs, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

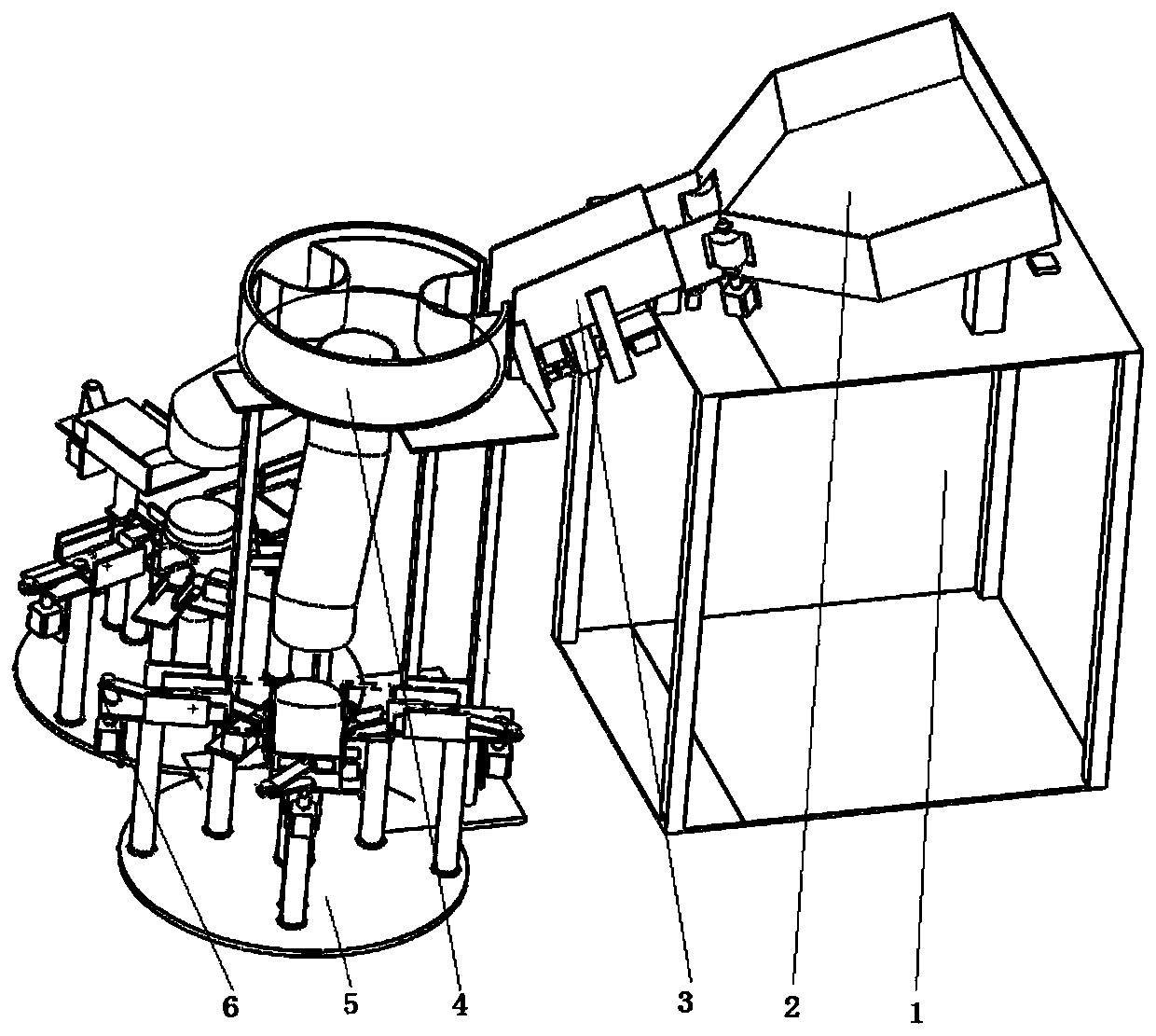

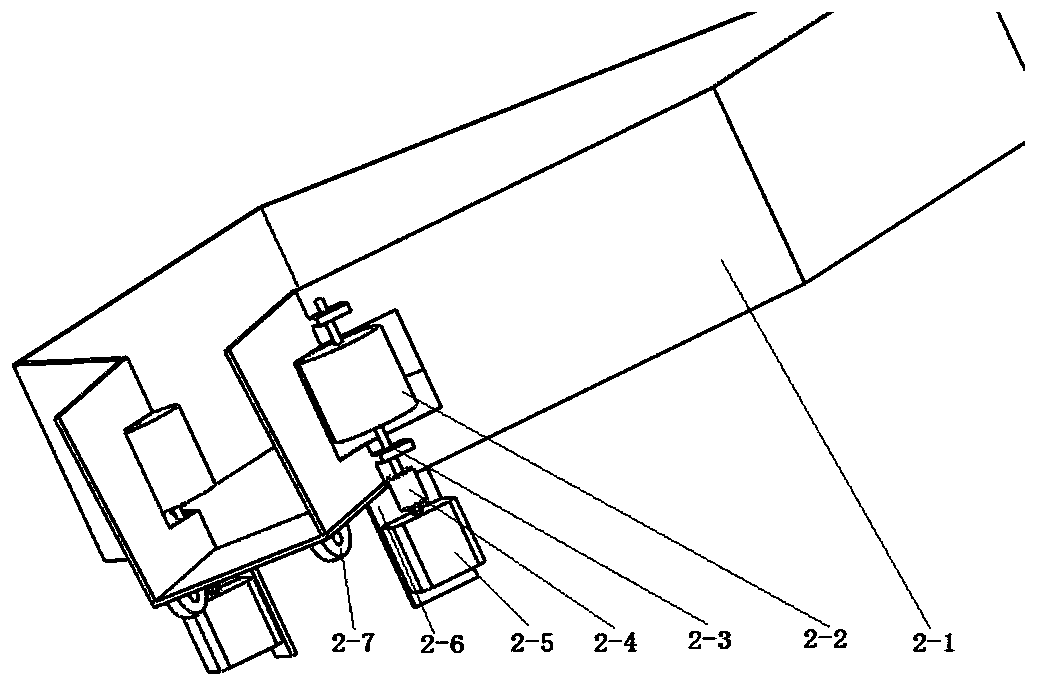

[0032] Such as figure 1As shown, a fruit automatic screening and packaging machine includes a feed hopper support 1, a feed hopper 2, an inclined slide 3, a fruit screening disc 4, a packaging device A5 and a packaging device B6. The feeding hopper 2 is set above the feeding hopper support 1 at a certain inclined angle; one end of the inclined slideway 2 is placed on the feeding hopper support 2, and the other end is placed on the support of the sieve fruit disc 4 for connecting the feeding hopper 2 and the sieve Fruit disc 4, so that the fruit to be packed can smoothly enter the fruit screening disc 4 from the feeding hopper 2 by gravity.

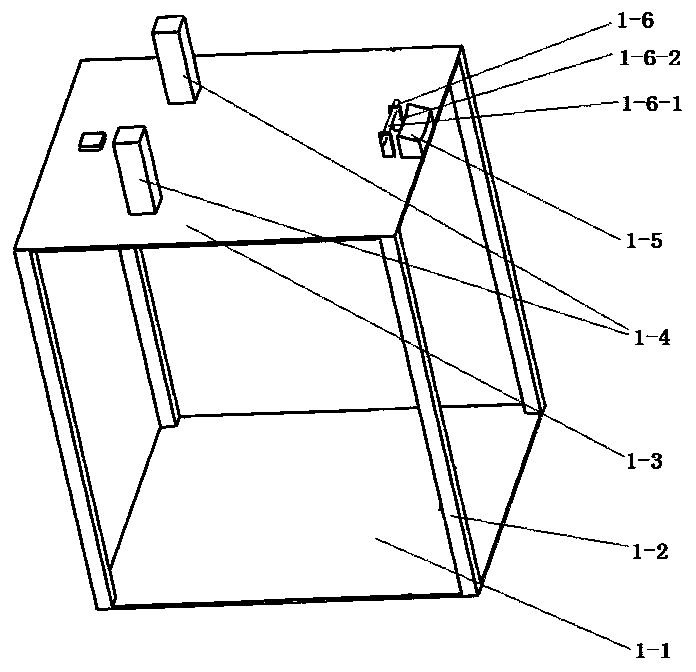

[0033] Such as figure 2 The feed hopper bracket 1 shown is used to support one end of the feed hopper 2 and the inclined slideway 3, and its structure mainly includes a bottom plate 1-1, a column 1-2, a platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com