Box stacking device

A palletizing device and box technology, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problem of low stacking efficiency of boxes, and achieve the effect of improving the stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

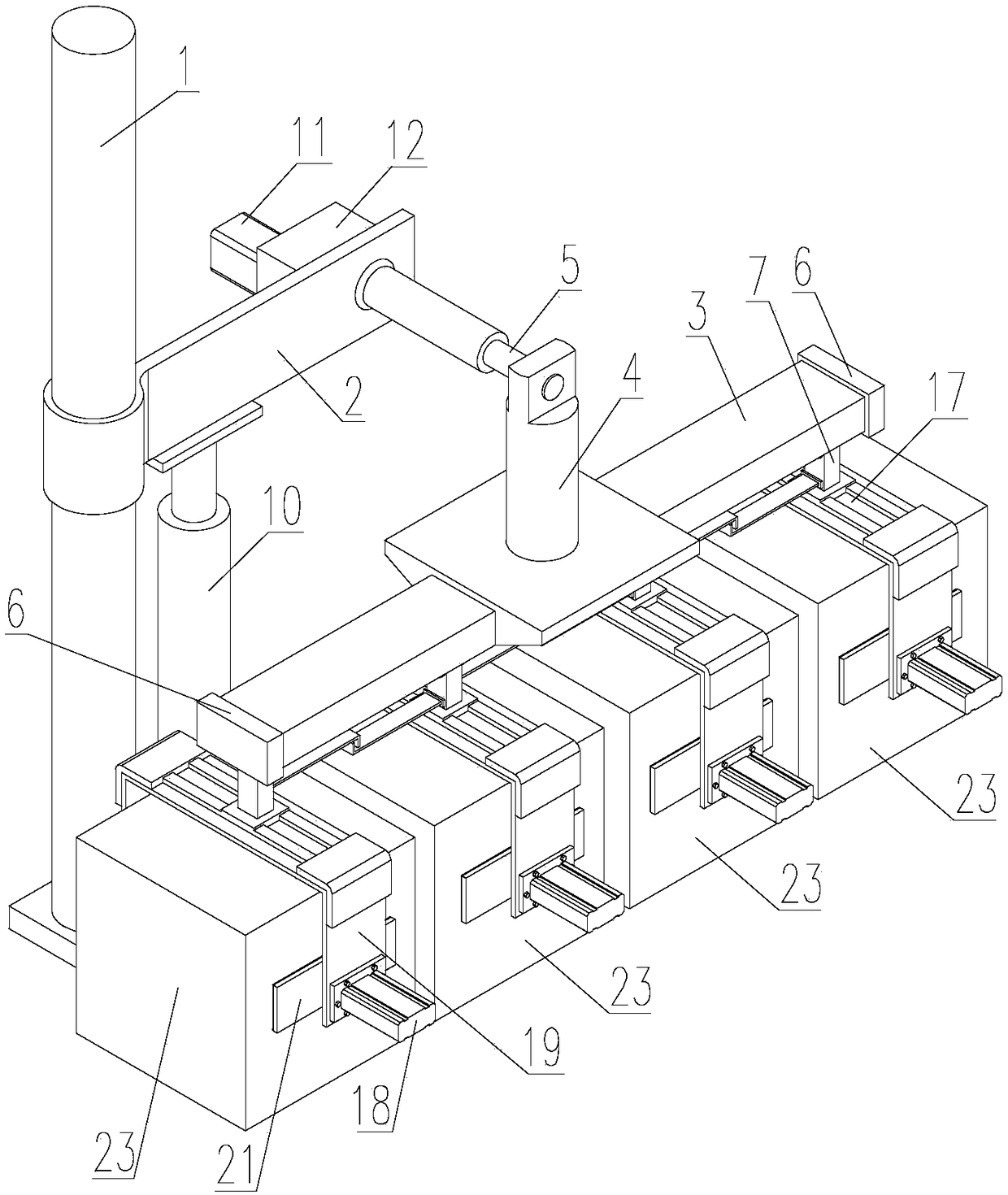

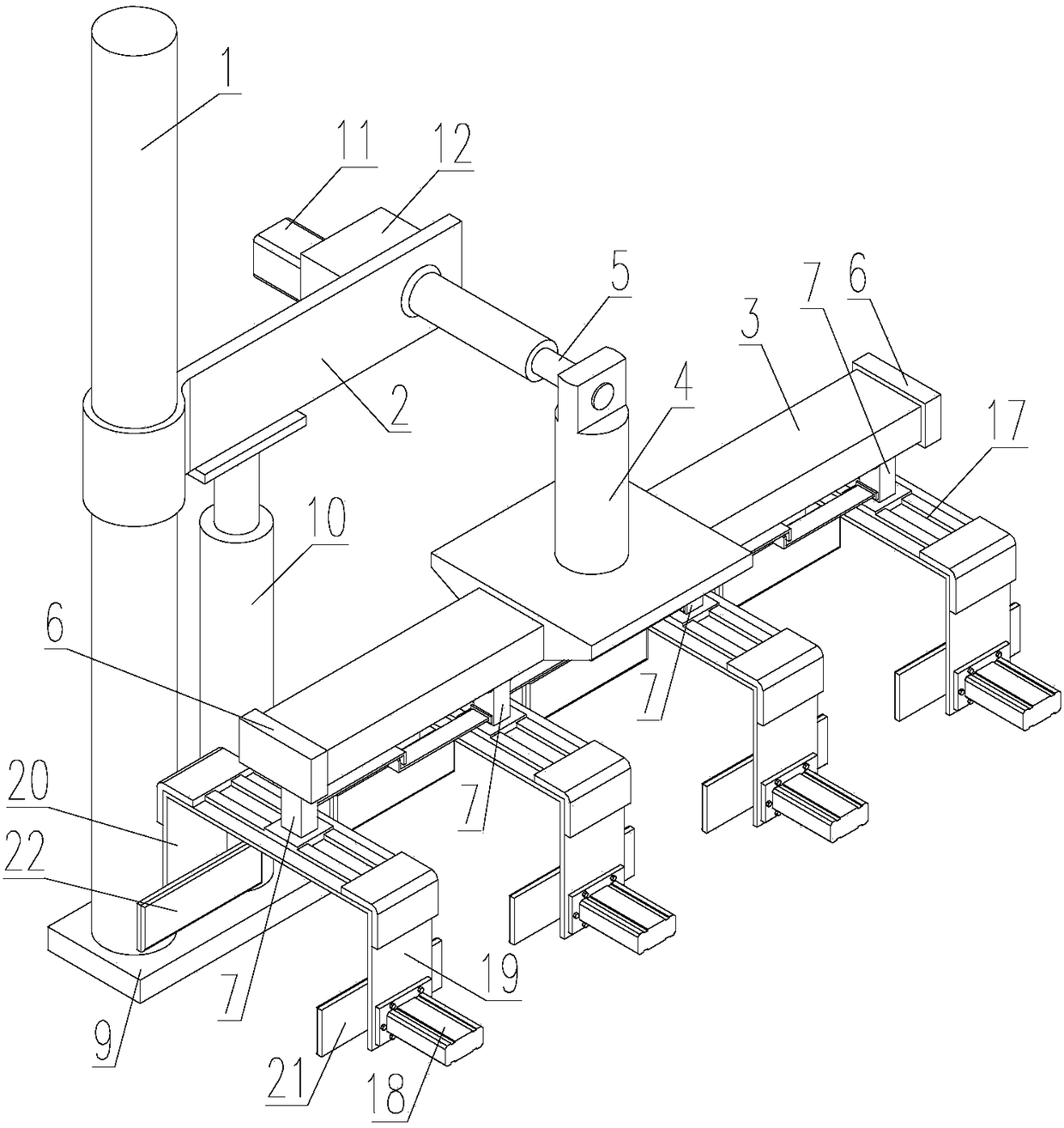

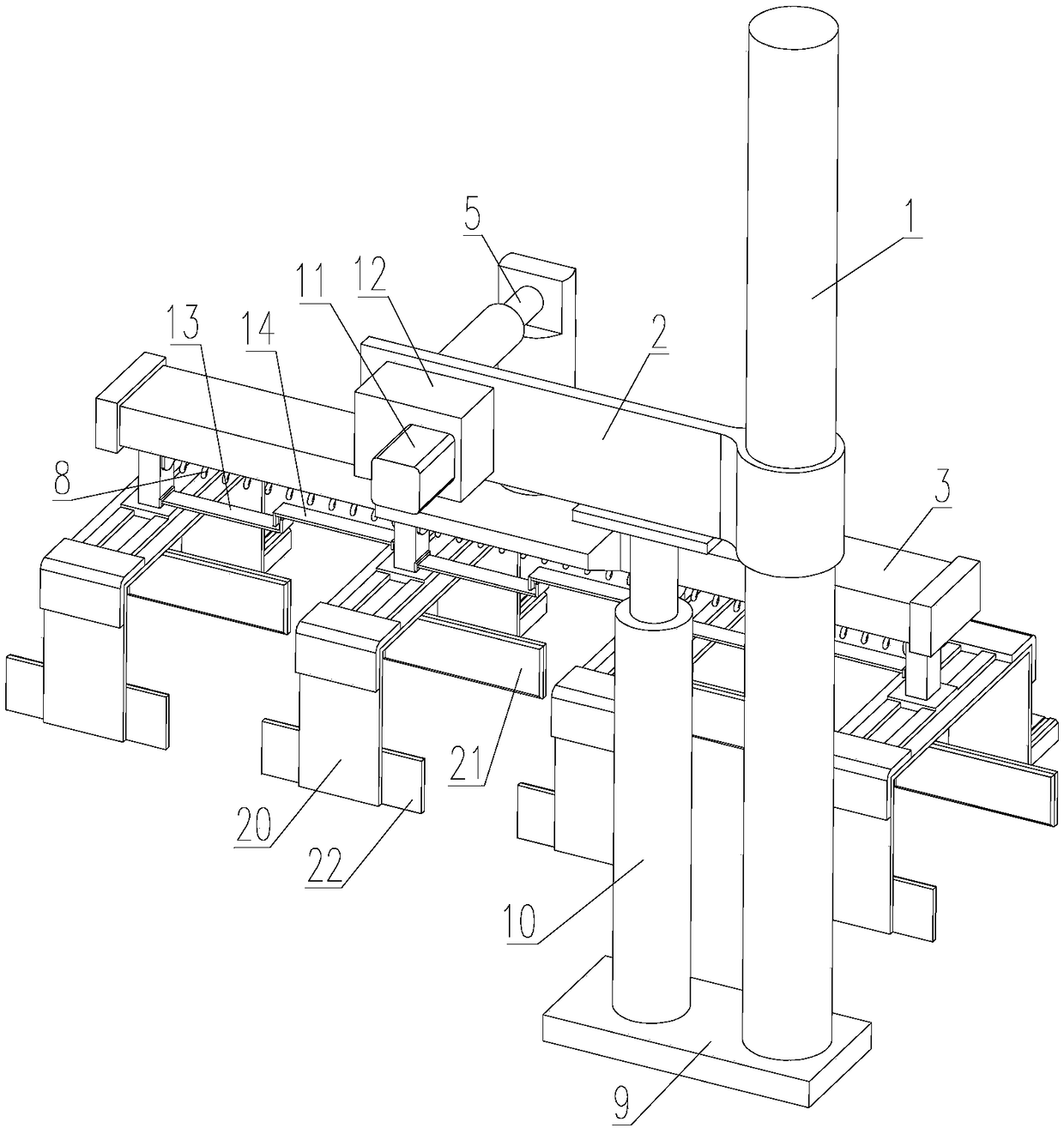

[0026] Such as Figure 1-9 As shown, a box palletizing device includes a column 1, a cantilever 2 and a crossbeam 3, the cantilever 2 is slidably arranged on the column 1, and the column 1 is fixed with a device for driving the cantilever 2 to rise or fall along the column 1. Jacking assembly, the upper surface of the beam 3 is fixed with a connecting frame 4, the connecting frame 4 is fixed with a rotating shaft 5, the rotating shaft 5 is connected with the cantilever 2 in rotation, and the cantilever 2 is fixed with a shaft for driving the rotating shaft 5 to rotate. flip component of

[0027] The crossbeam 3 is provided with a chute 3-1 along its length direction, and the two ends of the chute 3-1 on the crossbeam 3 are fixed with plugs 6, and there are many slides arranged in the chute 3-1. There are two suspension rods 7, each of which is fixed with a clamping assembly for clamping the box body 23, and a return spring 8 is fixed between two adjacent suspension rods 7.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap