Method for optimizing duty cycle in robotic system

A robot system, work cycle technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as non-optimal work cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the context of this disclosure, "cycle time" may refer to the time required for a robotic system to perform a task sequence once. However, due to the periodic nature of work cycles, subsequent work cycles may start before the previous work cycle is ready. Thus, the term "cycle time" may also refer to the average time required for a robotic system to perform a task sequence when performing a (mass) sequence of tasks.

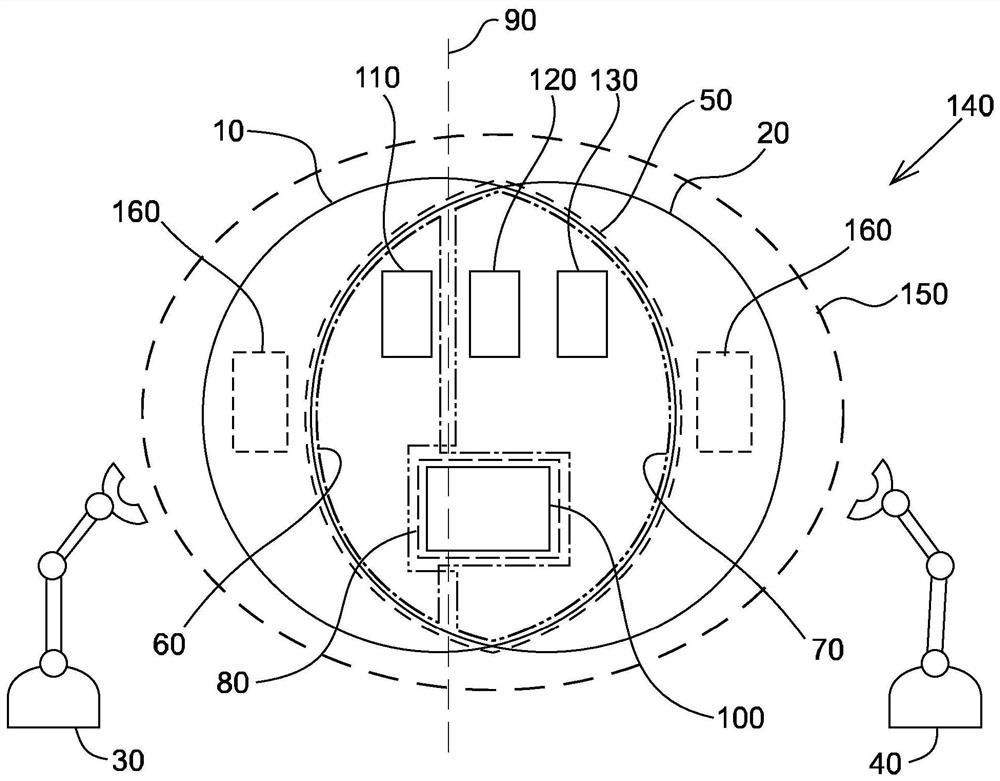

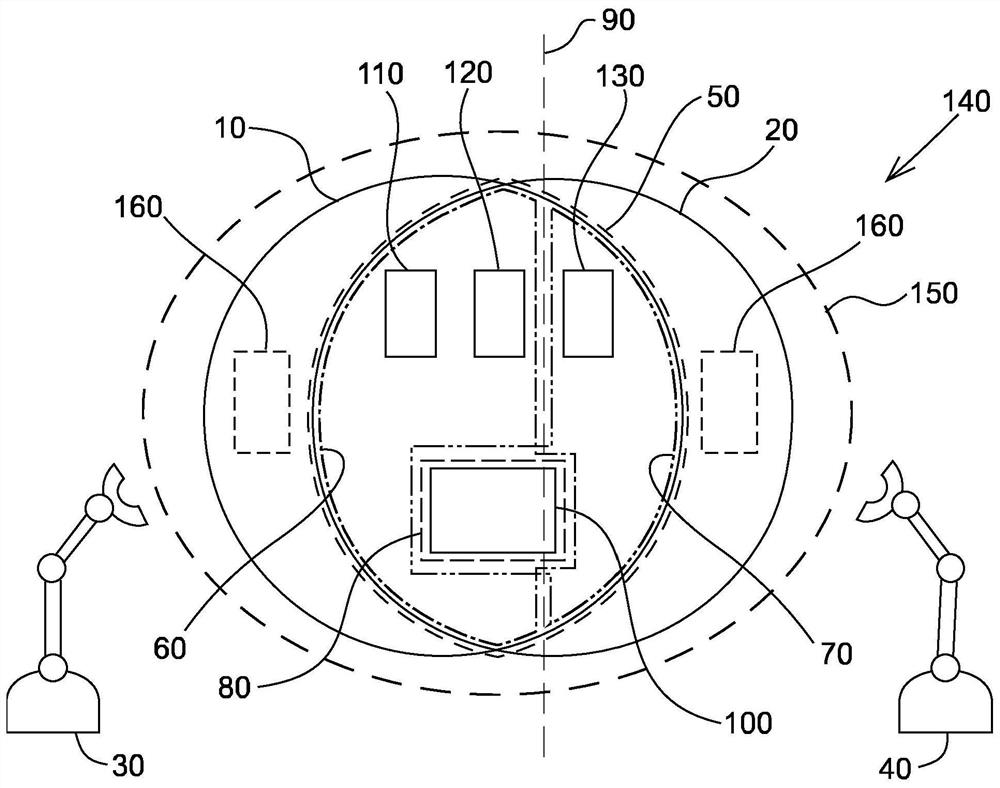

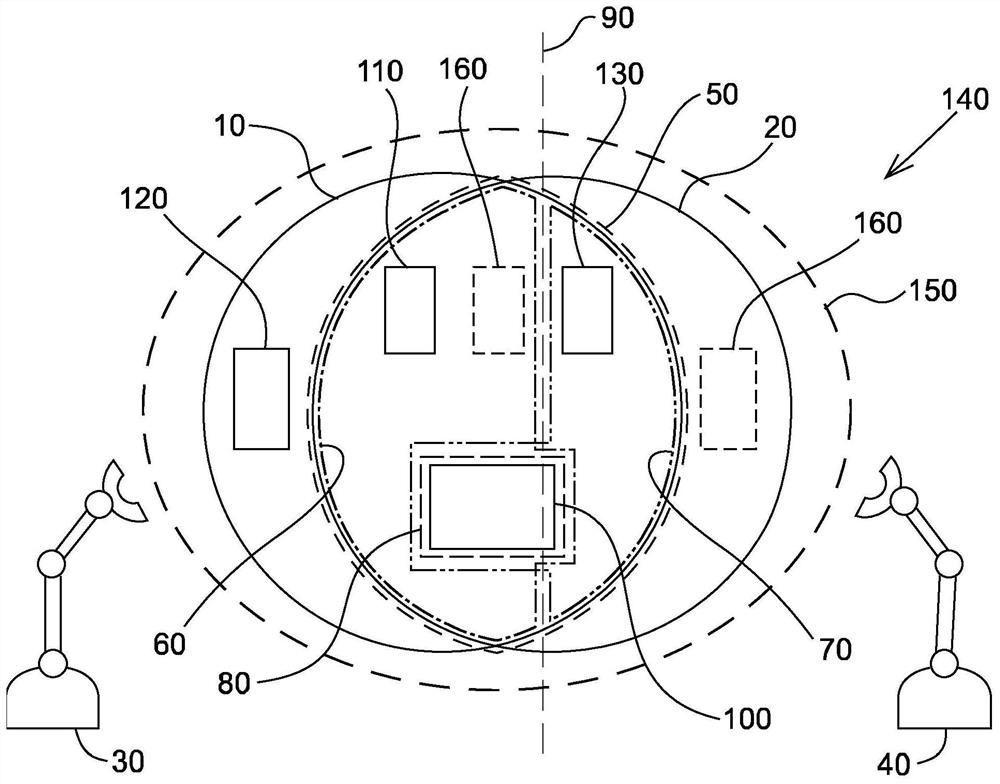

[0024] refer to figure 2 , given a layout with figure 1 The same in , and the overall task is the same (fit the three parts together at the fixture). However, the working area division differs in that the first feeder and the second feeder are assigned to the first manipulator, and only the third feeder is assigned to the second manipulator. suppose to pass figure 2 A division of the working area can be achieved than by figure 1 The work area division of the shorter cycle time, then the optimization problem is restricted to according to figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com