Thermally conductive composition via coating on plastics

A thermoplastic polymer, coating technology, applied in conductive coatings, reflective/signal coatings, radiation-absorbing coatings, etc., can solve problems such as high thermal conductivity, limited heat dissipation space, and undesired mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

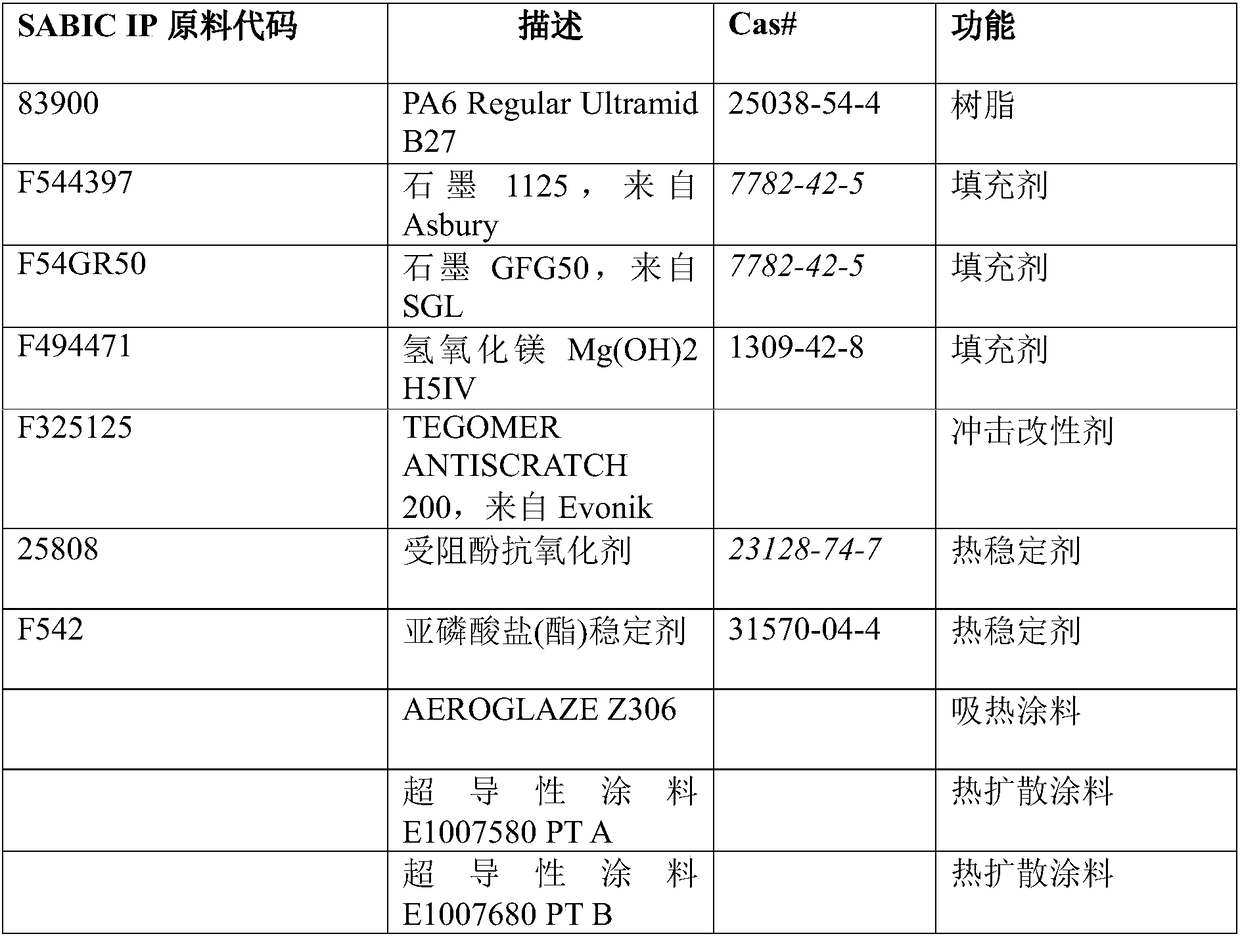

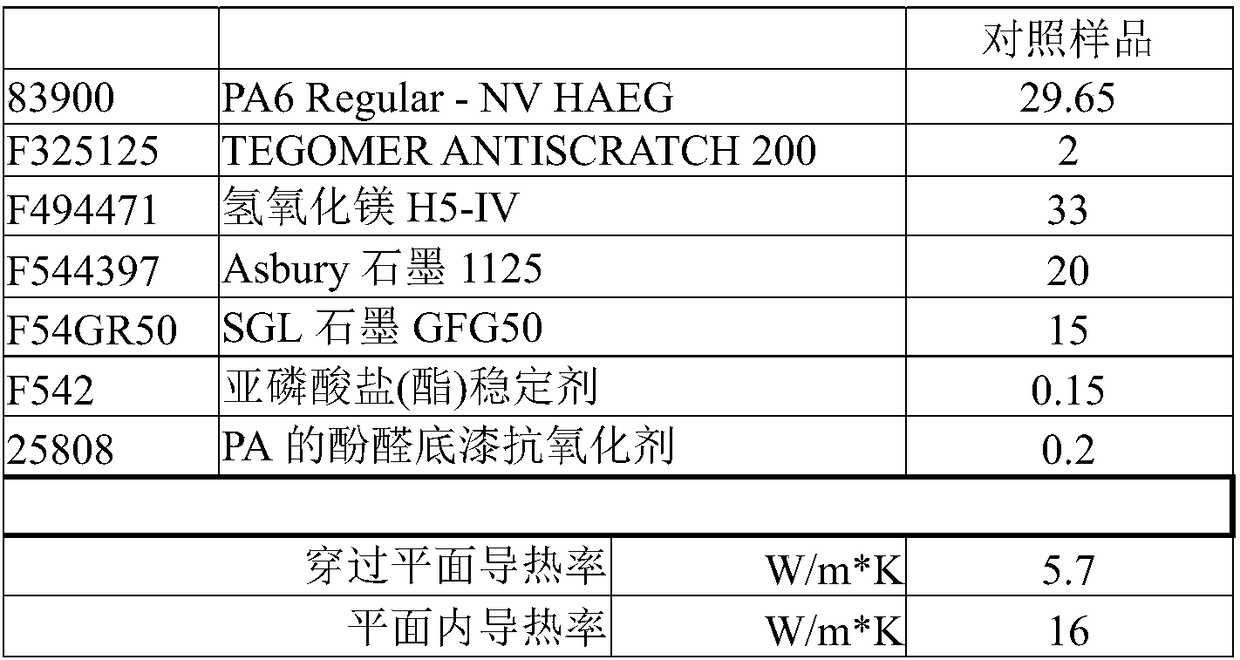

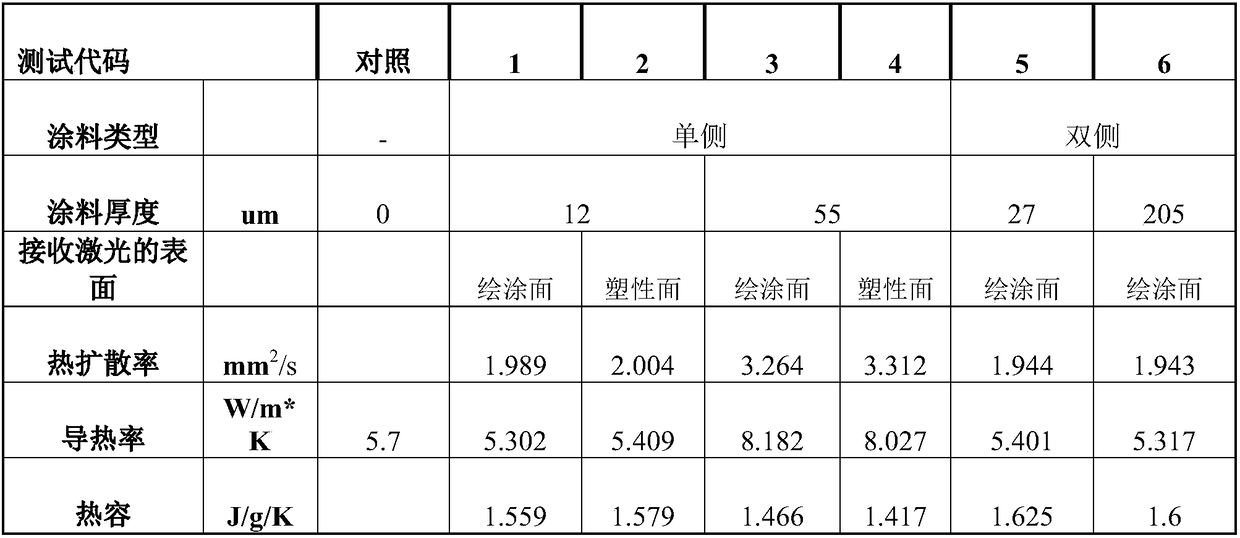

[0009] In one aspect, high thermal conductivity (e.g., greater than 2W / m*K, greater than 6W / m*K, 2W / m*K, and 30W / m * between K). It will be appreciated that the thermoplastic material may have a low level of thermal conductivity and that the thermal conductivity may be increased by the thermoplastic layer - by providing a coating. Table 1 illustrates a list of available raw materials. However, other resins, fillers, stabilizers, and coatings can be utilized to achieve the desired thermal conductivity, as described herein.

[0010] (1) Table 1. Raw material list

[0011]

[0012] In one aspect, the substrate may consist of or be formed from: polypropylene, polyethylene, vinyl copolymers, polycarbonate, polyamide, polyester, polybutylene terephthalate (PBT), polyethylene terephthalate Polyester (PET), polycyclohexylene terephthalate (PCT), liquid crystal polymer (LPC), polyphenylene sulfide (PPS), polyphenylene ether (PPE), polyphenylene ether-polystyrene blend Blends, Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap