Synergistic dispersants

A technology of dispersants and additives, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve problems such as harmful seals and increased corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0166] The following examples are illustrative, but not limiting, of the methods and compositions of the present application. Other appropriate modifications and adaptations of the various conditions and parameters commonly encountered in the art and apparent to those skilled in the art are within the spirit and scope of the application. All patents and publications cited in this application are hereby incorporated by reference in their entirety.

[0167] Tests to evaluate the measured effective concentration

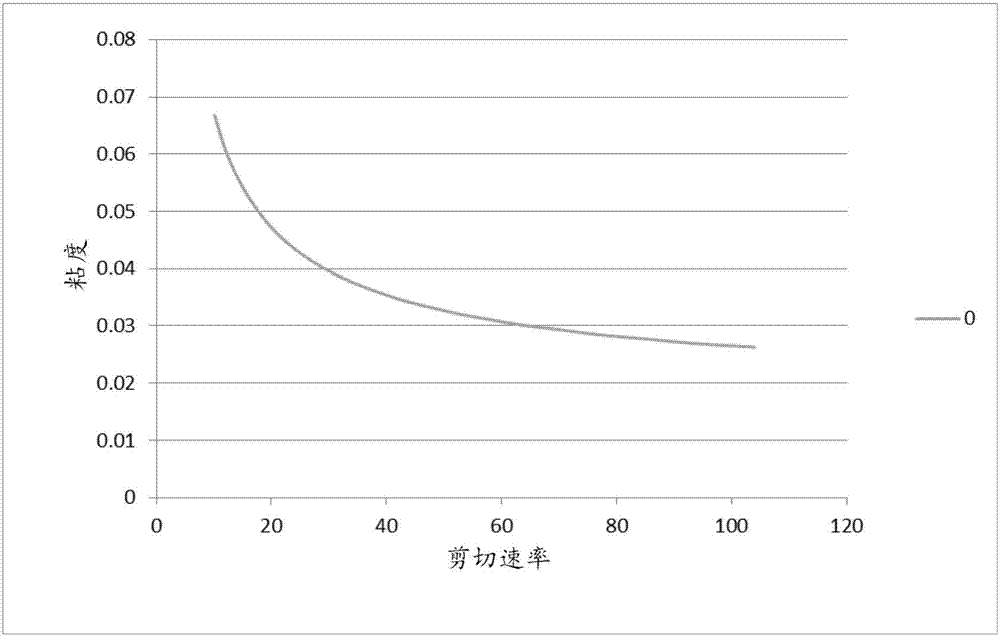

[0168] In order to evaluate lubricant formulations according to the present application, various dispersant combinations were tested for their ability to disperse soot. A sooting oil with 4.3 wt% soot was produced from a diesel fired engine using fluid without dispersant. The oil is then tested by shear rate sweeps in a cone and plate rheometer to determine Newtonian / non-Newtonian behavior.

[0169] The results for untreated soot-adhering oil are shown in figure 1 m...

Embodiment 1

[0193] Lubricant compositions were prepared using samples of the above-described sooting oil and an additive composition containing the two dispersants and the additional additives listed above. The first dispersant was PIBSA comprising a mixture of MW 1300 HR PIB and MW 2300MW PIB.

[0194] The second dispersant in the combination is the post-treatment reaction product of PIBSA (containing highly reactive PIB in a molar ratio of SA:PIB of 1.75:1) with tetraethylenepentamine in a molar ratio of PIBSA:amine of 4: 3 to 2:1. The reaction product is then worked up with naphthalic anhydride. The weight percent of the first dispersant in the lubricant composition was kept constant at 29.5 wt% to provide the lubricant composition with 2.25 wt% polymer, based on the total weight of the lubricant composition. The weight percent of the second dispersant was varied to provide different amounts of the polymer of the second dispersant to the lubricant composition, based on the total weig...

Embodiment 2

[0197] Lubricant compositions were prepared using samples of the above-described sooting oil and an additive composition containing the two dispersants and the additional additives listed above. The first dispersant in the combination is the reaction product of highly reactive PIB and succinic anhydride SA (SA:PIB molar ratio 1.15:1) with a mixture of triethylenetetramine and E-100 (bottom product), where The molar ratio of PIBSA:amine is from 4:3 to 2:1.

[0198] The second dispersant in the combination is a work-up reaction product of a mixture of highly reactive PIB and succinic anhydride (SA:PIB molar ratio 1.75:1) with triethylenetetramine and E-100 (bottom product), Wherein the molar ratio of PIBSA:amine is 4:3 to 2:1. The product is then worked up with a mixture of naphthalic anhydride and maleic anhydride. The weight percent of the first dispersant in the lubricant composition was kept constant at 50% by weight to provide the lubricant composition with 1.65% by weigh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap