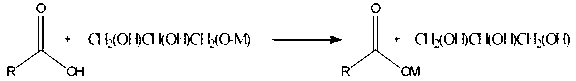

Alkali and earth alkali metal glycerates for drying and deacidification of fatty acid esters

A technology of alkaline earth metal and glycerate, which is applied in the direction of fatty acid esterification, fat generation, metal alcohol preparation, etc., and can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] The content of alkali metal glycerate was determined by potentiometric titration. During this process, glycerate was dissolved in deionized water by stirring for 5 min and the solution was titrated to the equivalence point with 0.25 molar sulfuric acid.

[0073] The water content is determined according to DIN 51777 "Determination of water content by the Karl Fischer direct method". The solvent is methanol, and the detection is performed amperometrically at double platinum electrodes.

[0074] The soap content is determined by titration according to the standard method of the DGF (German Society for Fat Science), method C-III 15 (97) "Seife in Ölen und Fetten", published in "Deutsche Einheitsmethoden zur Untersuchung von Fetten, Fettprodukt, Tensiden und verwandten Stoffen". Here, samples are dissolved in ethanol or acetone and titrated with 0.1 molar hydrochloric acid against bromophenol blue as indicator. Alternatively, endpoints can be determined potentiometricall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap