sink installation tool

A technology for installing tools and sinks, which is applied in the direction of manufacturing tools and hand-held tools, etc. It can solve the problems of difficult installation of fasteners, narrow gap between the sink and the table wall, etc., and achieve the effect of reducing installation difficulty, avoiding rotation, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is described in further detail.

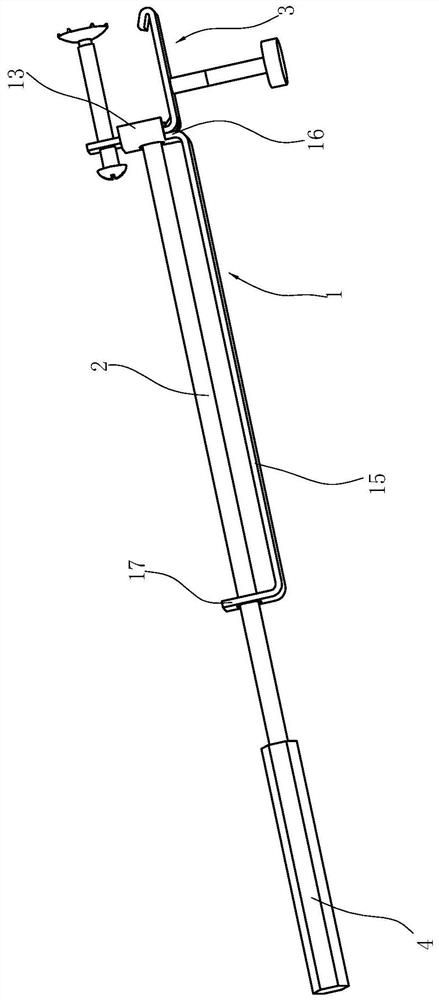

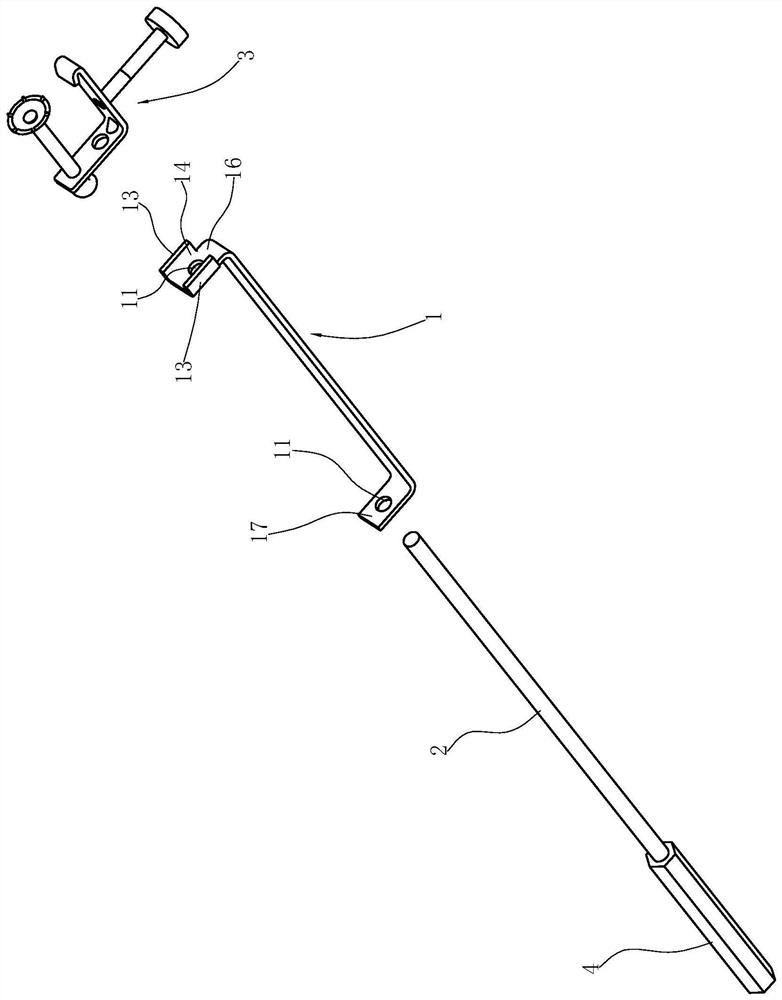

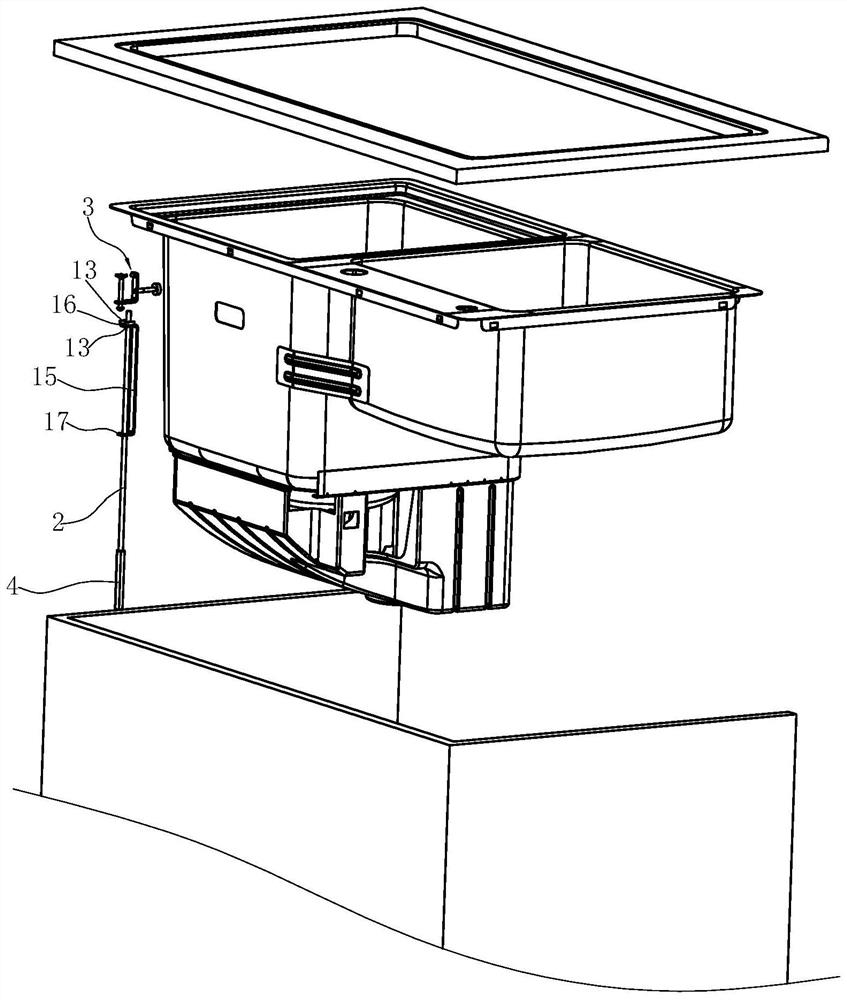

[0021] Such as Figure 1 to Figure 5 As shown, the sink installation tool includes a support piece 1 and a connecting rod 2 .

[0022] Wherein, the support member 1 has a middle part 15 parallel to the connecting rod 2, an upper bent part 16 and a lower bent part 17 perpendicular to the middle part 15, and the upper and lower bent parts 16, 17 are provided with a connecting rod. 2 passes through the through hole 11, and the two opposite sides of the upper bent portion 16 also have upwardly bent baffles 13, and the two baffles 13 and the upper bent portion 16 form a limiting groove 14.

[0023] In this embodiment, the through hole 11 is an internally threaded hole.

[0024] Connecting rod 2 can adopt screw rod, and its top has external thread, can pass through through hole 11 and be threaded on the fastener 3;

[0025] Here's how to use the sink installation tool:

[0026] Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com