Selective oxidation method for furan alcohol or aldehyde compound

An aldehyde compound, furan alcohol technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc. Simple process, mild conditions and good catalyst stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

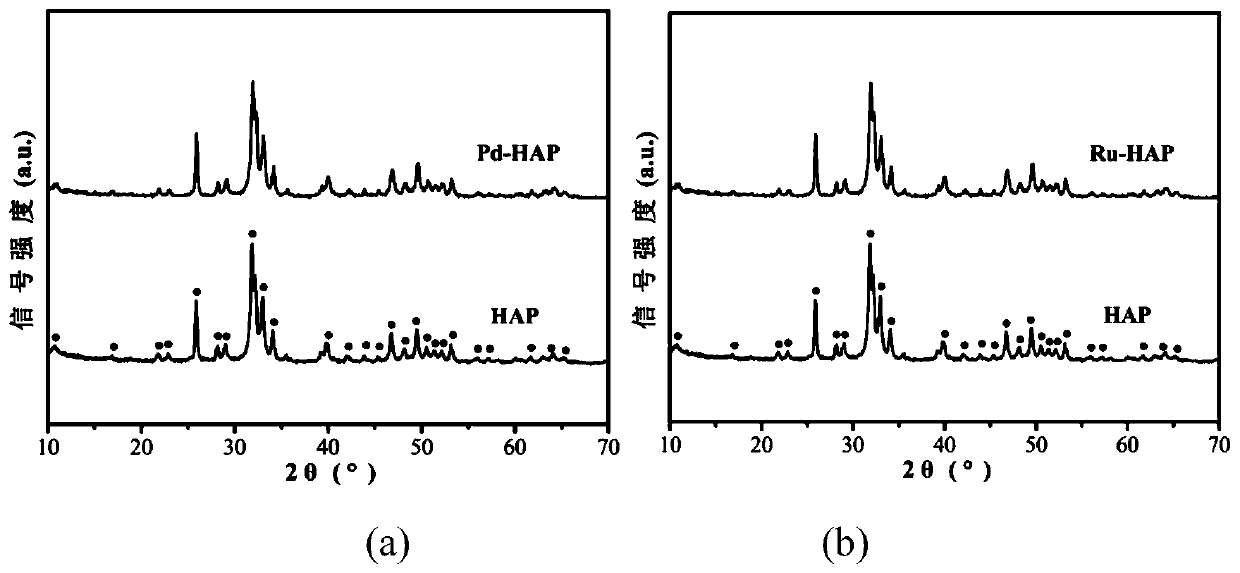

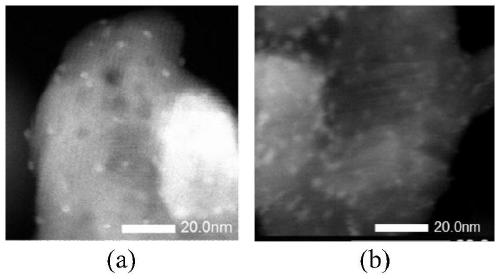

[0048] Using the method described above, the active metals Ru, Pd, Pt, Ir, Co, Cu, and Ni were respectively loaded onto the apatite support Ca 5 (PO 4 ) 3 (OH), Mg 2 Ca 3 (PO 4 ) 3 (OH), Ce 5 (VO 4 ) 6 (OH) 2 , Ca 5 (PO 4 ) 3 (HCO 3 ), Na 10 (PO 4 ) 3 (OH), Ca 5 (PO 4 ) 3 F or Na 10 (PO 4 ) 3 (OH), thus obtaining the corresponding supported catalyst (see Table 1 for details). These catalysts were respectively used at 150°C and 1MPa oxygen in water solvent for 3h to catalyze the oxidation of HMF to prepare FDCA.

[0049] Specifically, 50 mg of HMF was added to a 50 mL reactor, and in the presence of the metal-loaded catalyst, 10 mL of water was added, the high-pressure oxygen cylinder was connected to the reactor, and the reactor was replaced by 6 inflation and deflation processes. Finally, set the oxygen pressure gauge to 1MPa by controlling the rotation of the pressure reducing valve, and use the programmed temperature control heating mantle to heat to ...

Embodiment 9-14

[0051] Using metal-loaded catalysts with different metal loadings (0.5-5% by mass), at 100° C., 2 MPa hydrogen, in n-hexane solvent, reacted for 15 h, and catalyzed the oxidation of HMF to prepare FDCA.

[0052] Specifically, 50 mg of HMF was added to a 50 mL reactor, and in the presence of the metal-loaded catalyst, 10 mL of n-hexane was added, the high-pressure oxygen cylinder was connected to the reactor, and the reactor was subjected to 6 inflation and deflation processes. Ventilate, and finally set the oxygen pressure gauge to 2MPa by controlling the rotation of the pressure reducing valve, and use the programmed temperature control heating mantle to heat to 100°C. Under the condition of magnetic stirring, after 15 hours of reaction, put the autoclave into the cold water bath for After cooling, vent the pressure in the reaction kettle, filter the mixture of catalyst and reaction solution with a filter membrane to separate the catalyst from the reaction solution, dilute the...

Embodiment 15~27

[0054] Use different metals Ru, Pd, Ir, Co, Cu, Ni or their combination Pd-Ir, Pd-Cu, Ru-Co, Cu-Co, Pd-Ni to load on the apatite carrier respectively (active component The metal-supported catalyst prepared by the loading amount of 1% by weight) was reacted for 4 hours at 80° C. and 2 MPa air in a γ-butyrolactone (GBL) solvent to catalyze the oxidation of HMF to prepare FDCA.

[0055] Specifically, 50 mg of HMF was added to a 50 mL reactor, and in the presence of the metal-supported catalyst, 10 mL of GBL was added, the high-pressure air bottle was connected to the reactor, and the reactor was replaced by 6 inflation and deflation processes. Finally, set the air pressure gauge to 2MPa by controlling the rotation of the pressure reducing valve, and use the programmed temperature control heating mantle to heat to 80°C. Under the condition of magnetic stirring, after 24 hours of reaction, put the high pressure reactor into a cold water bath for cooling After cooling, the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com