Wire guiding device of elasticizer

A wire guide device and texturing machine technology, applied in the direction of textiles and papermaking, etc., can solve the problems of reducing work efficiency and processing quality, inconveniently observing whether the wire is broken, and the wire guide device cannot flexibly adjust the position, angle and height of the guide wire, etc. , to achieve the effect of fast wiring, ensuring textile efficiency and quality, and avoiding shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

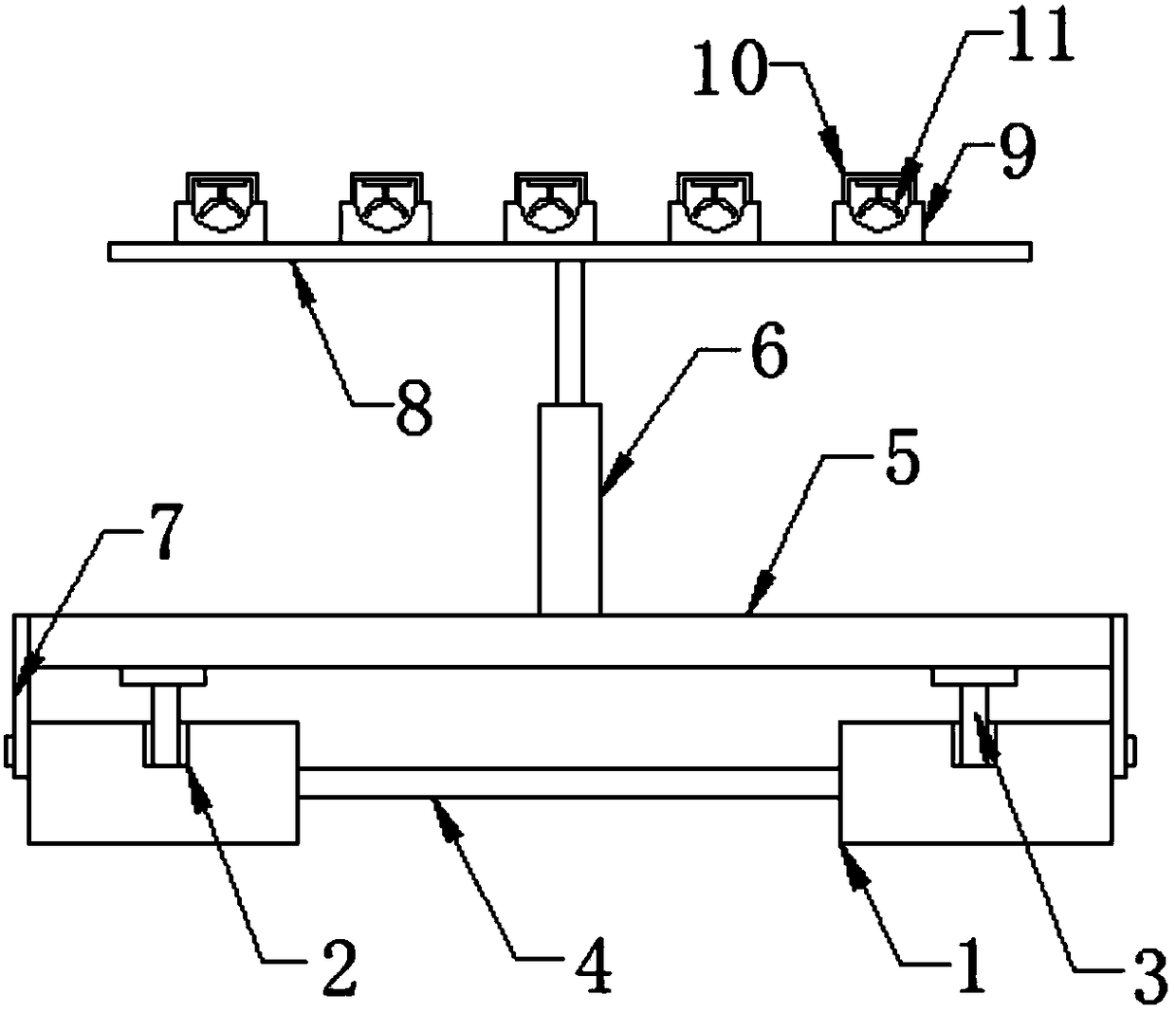

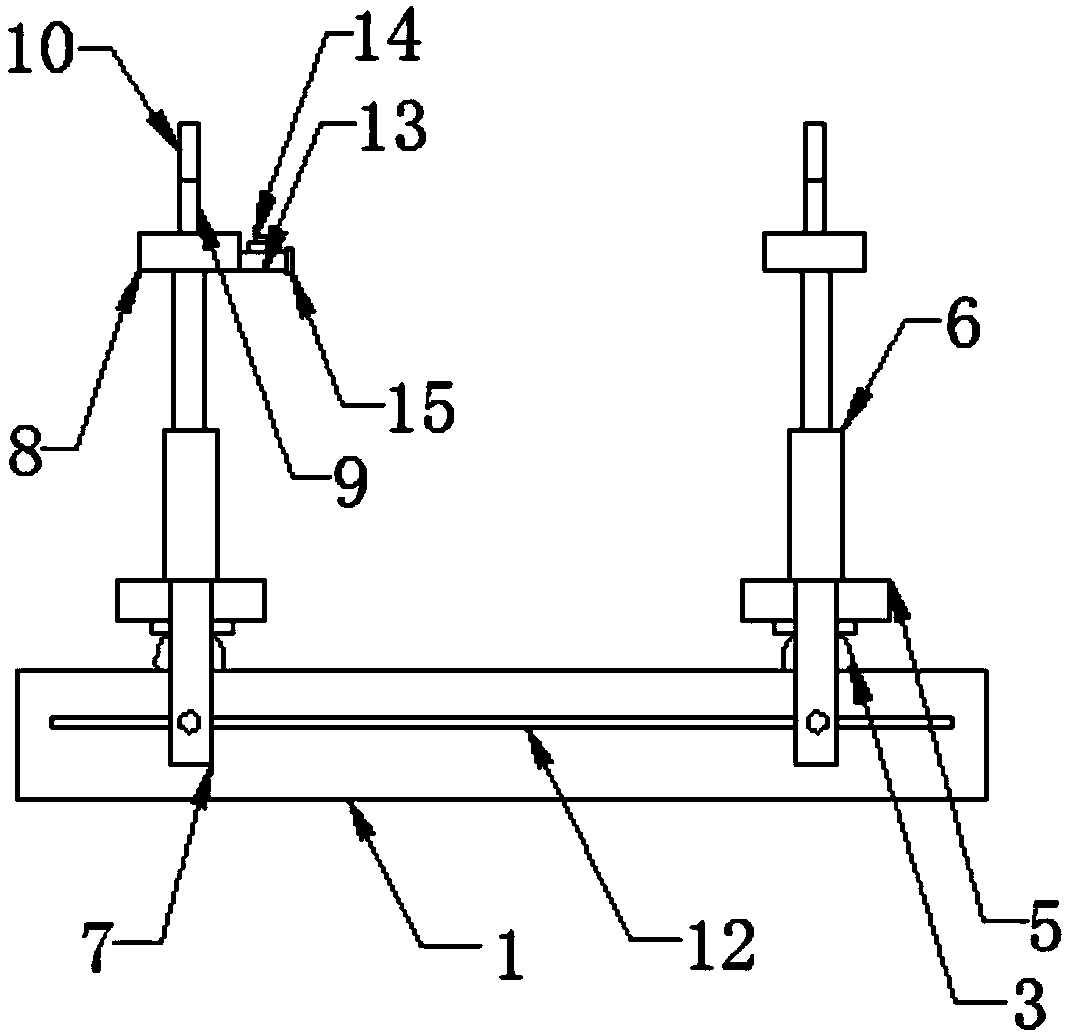

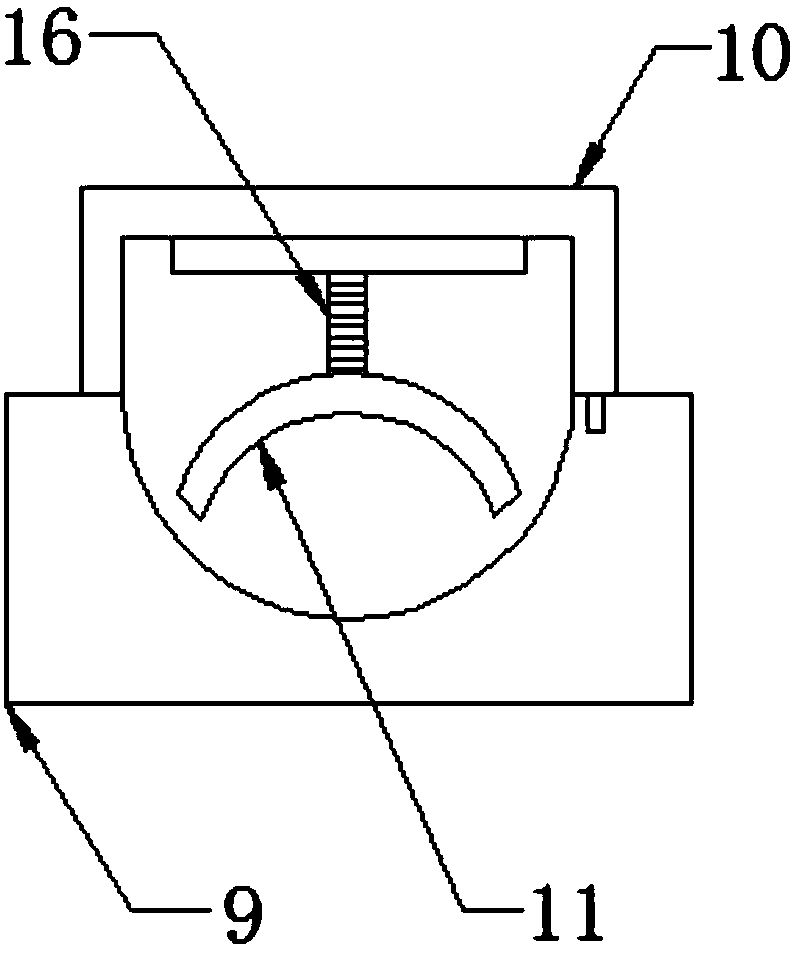

[0023] Such as Figure 1-4 As shown, a wire guide device of a texturing machine in the present invention includes: two strip-shaped bases 1, two moving plates 5 and two electric telescopic rods 6, and several connecting rods are passed between the two strip-shaped bases 1 4 connection, the tops of the two bar-shaped bases 1 are provided with bar-shaped wheel grooves 2, the two sides of the top of the two bar-shaped bases 1 are provided with moving plates 5, and both sides of the moving plates 5 are fixed with fixed plates 7 , one side of the two bar-shaped bases 1 is provided with a locking groove 12, and the center of the top of the two moving plates 5 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com