Rotary drilling machine with automatic counterweight device

A technology of a counterweight device and a rotary drilling rig, which is applied in directions such as rotary drilling rigs, rotary drilling, and counterweights, can solve the problem that the counterweight mechanism cannot counterbalance the weight in time, and can solve the problem that the counterweight cannot be counterbalanced in time and improve the counterweight. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

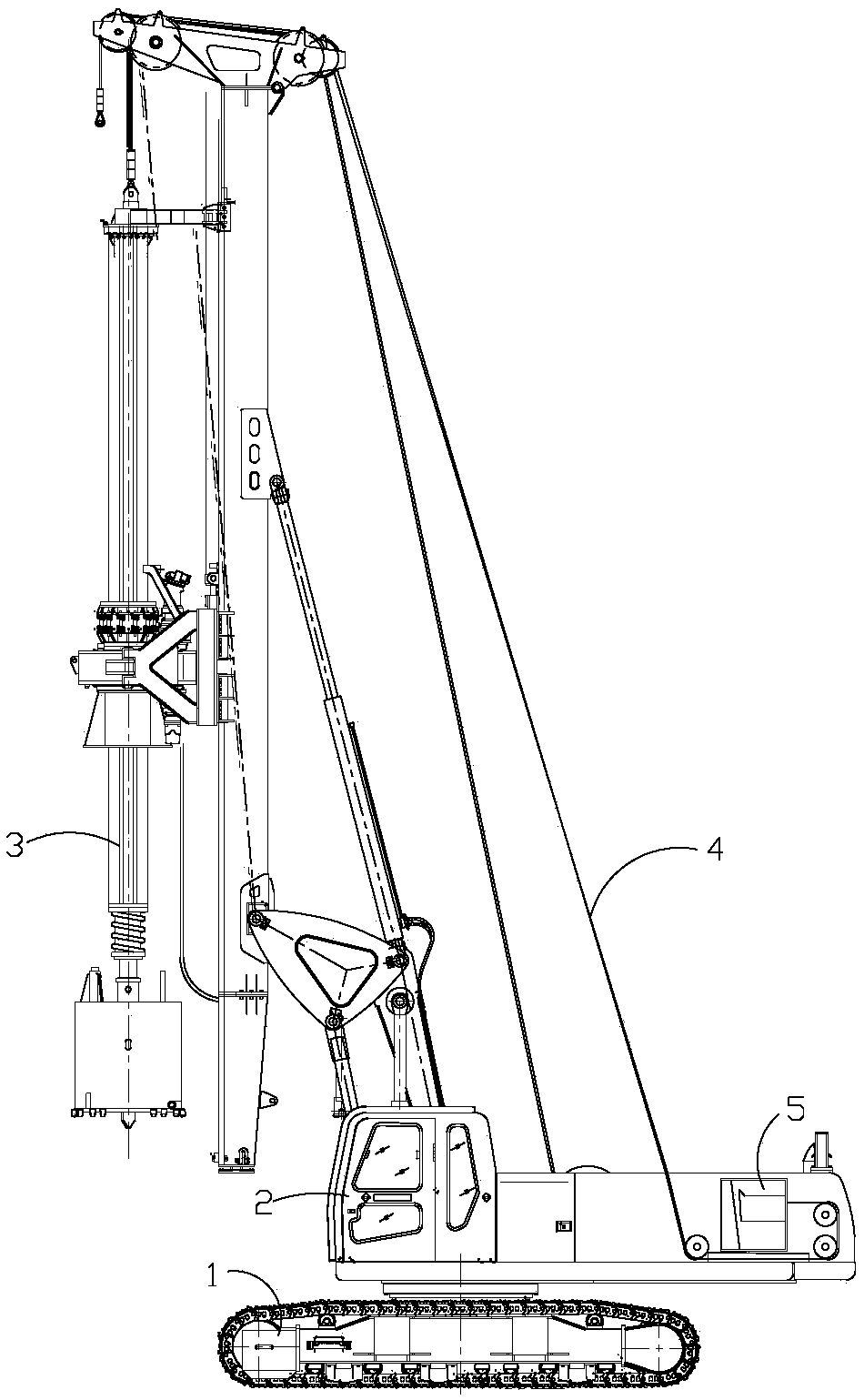

[0015] As shown in the figure, in this embodiment, a rotary drilling rig with an automatic counterweight device includes a traveling mechanism 1, an operating mechanism 2, a drilling bucket mechanism 3 and a cable 4, and the above four constitute the whole of the rotary drilling rig The structure also includes a counterweight mechanism 5. In order to facilitate operation, the operating mechanism 2 is provided with a console, and the front and rear ends of the console are respectively provided with a drilling bucket mechanism 3 and a counterweight mechanism 5. The drilling bucket mechanism 3 rotates for construction, and the counterweight Mechanism 5 to balance its weight, drill bucket mechanism 3 is connected with counterweight mechanism 5 through cable 4;

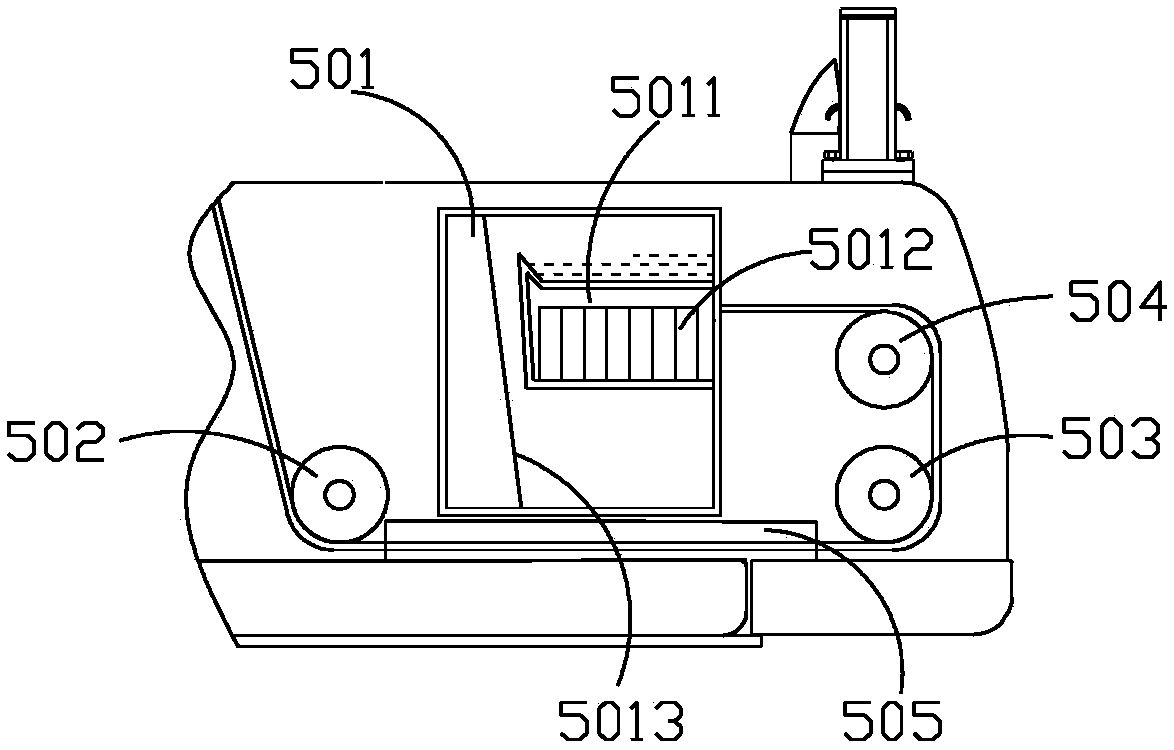

[0016] In this embodiment, the counterweight mechanism 5 includes a sliding platform 505 and a counterweight box 501 slidingly arranged with the sliding platform 505, and the position of the center of gravity of the counter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com