Assembly method of pin-type hub brake disc assembly for commercial vehicles

An assembly method and brake disc technology, applied in the direction of brake discs, brake parts, brake types, etc., can solve the problems of laborious and time-consuming installation of fixing bolts, and achieve the effects of saving time and labor, reducing weight and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

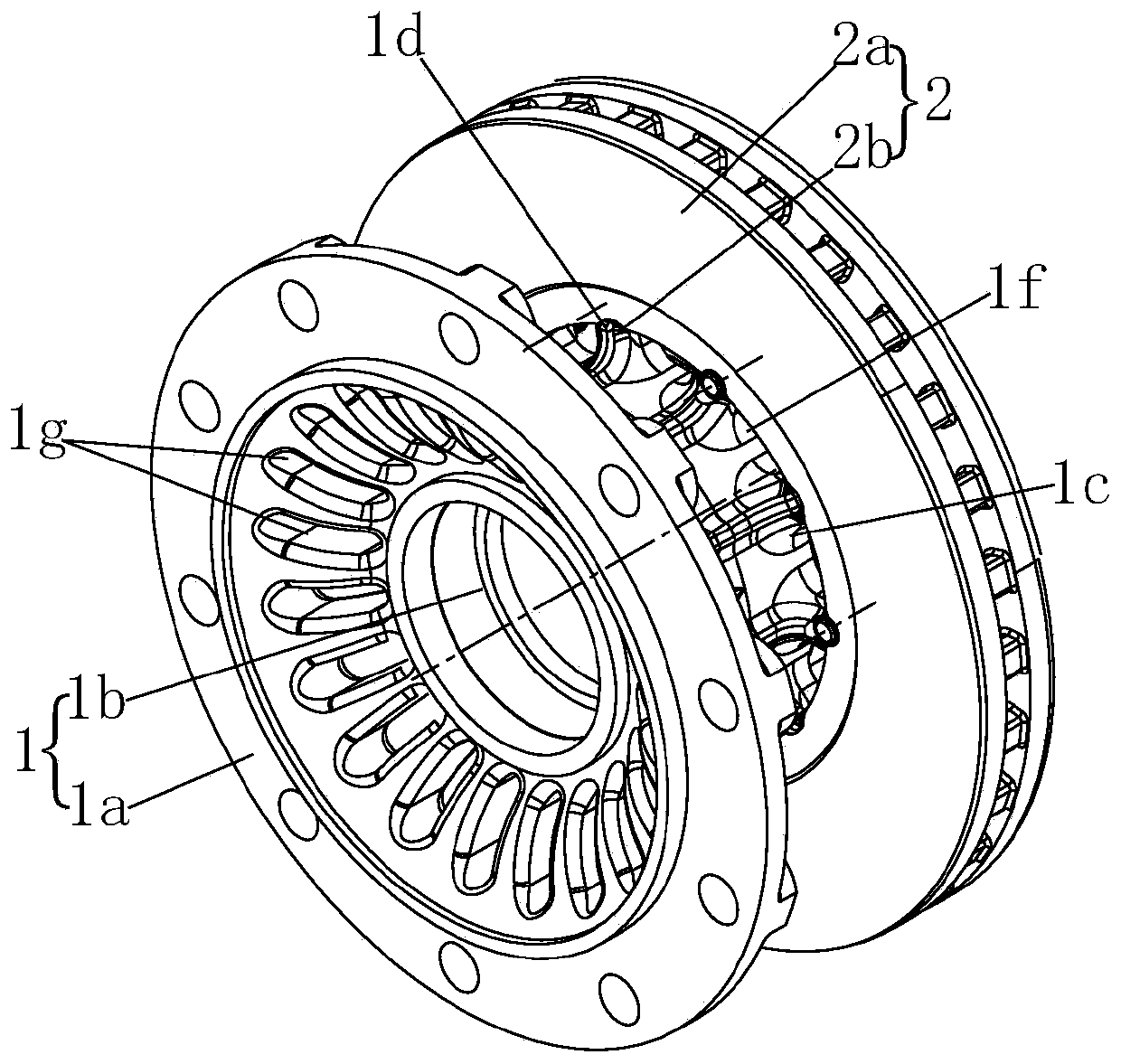

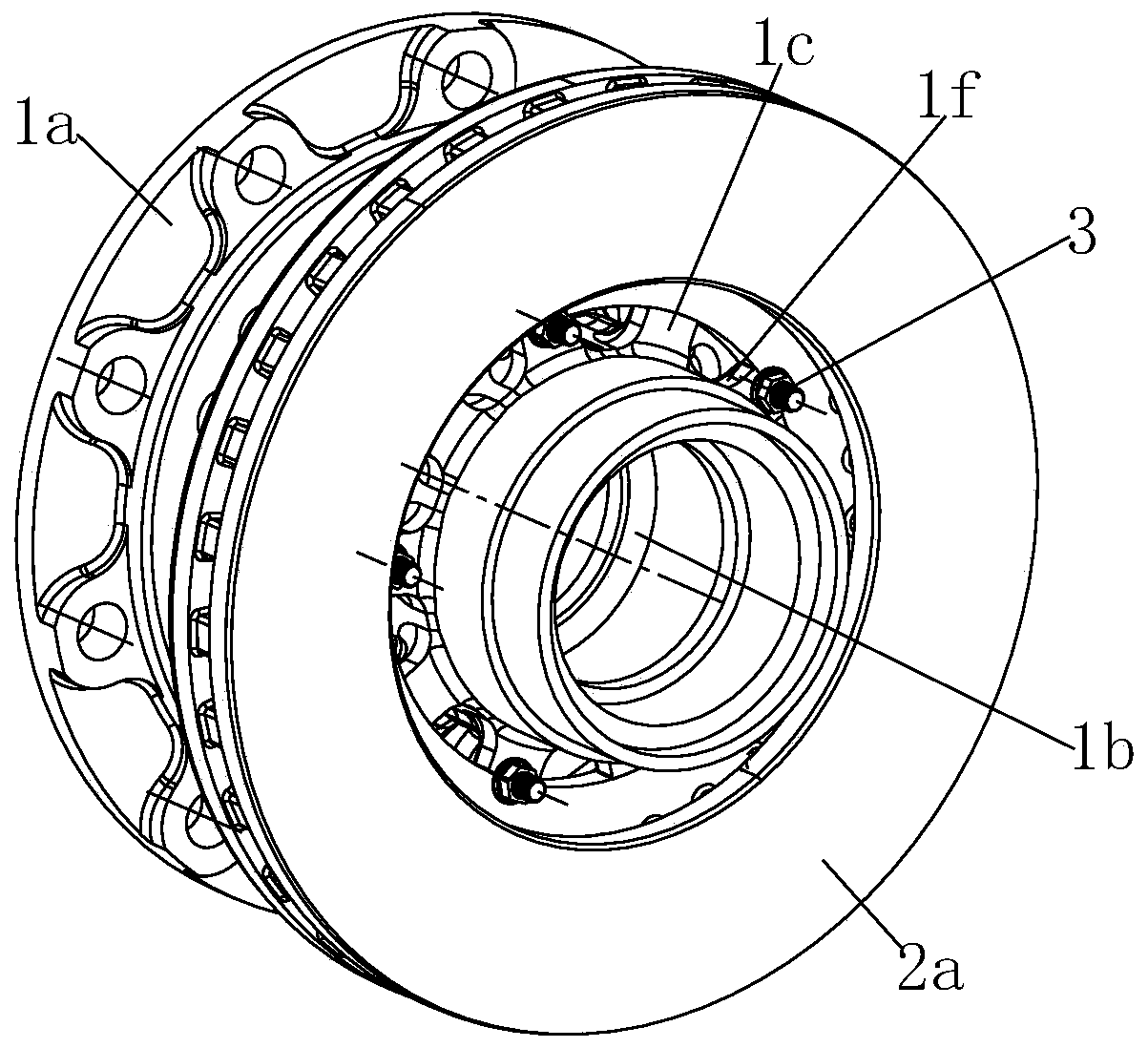

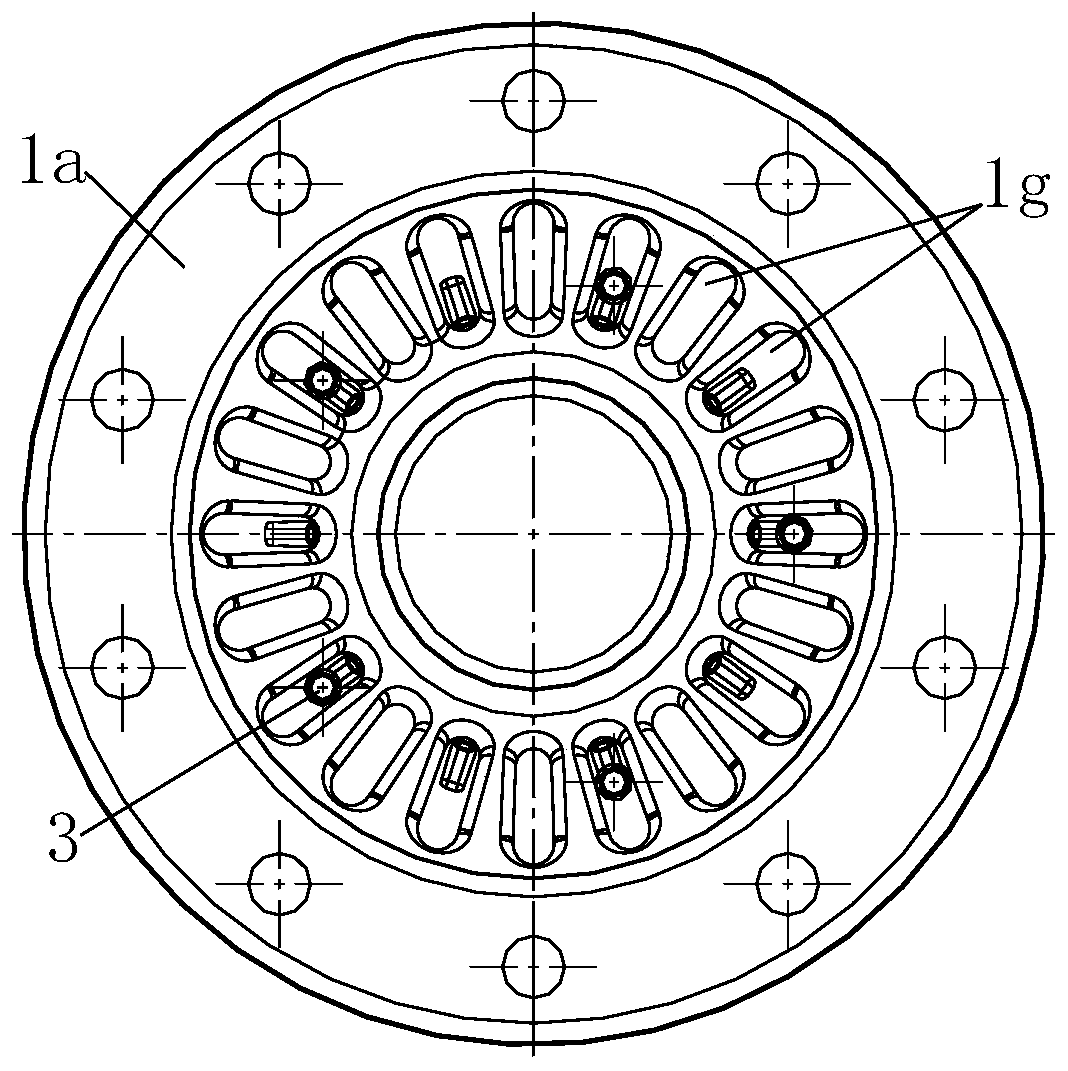

[0049] This embodiment provides an assembly method for a pin-type hub brake disc assembly for a commercial vehicle. The hub brake disc assembly includes a hub 1 and a brake disc 2, wherein the hub 1 consists of a hub The flange 1a and the hub bearing position 1b are composed. The brake disc 2 includes a brake disc body 2a, and the inner ring of the disc on the side of the brake disc body 2a facing the hub 1 is provided with several A connection keyway 2b, on the outer wall of the hub bearing position 1b corresponding to the position where the brake disc body 2a is installed, a connection spline 1c matching the connection keyway 2b is provided along the circumferential direction, the brake disc body 2a is installed on the hub bearing position 1b through the connecting keyway 2b and the connecting spline 1c, and the connecting spline 1c is on the side facing the hub flange 1a and on the outer wall of the hub bearing position 1b The corresponding position is provided with a posit...

Embodiment 2

[0059] This embodiment provides a pin-type hub brake disc assembly for commercial vehicles, including a hub 1 and a brake disc 2, wherein the hub 1 is composed of a hub flange 1a and a hub bearing position 1b, the The brake disc 2 includes a brake disc body 2a, the inner ring of the disc on the side of the brake disc body 2a facing the hub 1 is provided with several connecting key grooves 2b along the circumferential direction, and the hub bearing position 1b The position corresponding to the installation of the brake disc body 2a on the outer wall is provided with a connecting spline 1c matching with the connecting keyway 2b along the circumferential direction, and the brake disc body 2a is connected to the connecting keyway 2b through the connecting keyway 2b. The spline 1c is installed on the hub bearing position 1b, and the side of the connecting spline 1c facing the hub flange 1a is provided with a positioning reinforcing rib 1d at a position corresponding to the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com