Energy-saving type precise pressure regulating valve improved structure

A technology of precision pressure regulating valve and improved structure, which is applied in the direction of functional valve type, safety valve, balance valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Generally according to the present invention, the best available embodiment, and cooperate with Figure 1-Figure 7 After detailed description, the understanding of the present invention can be increased;

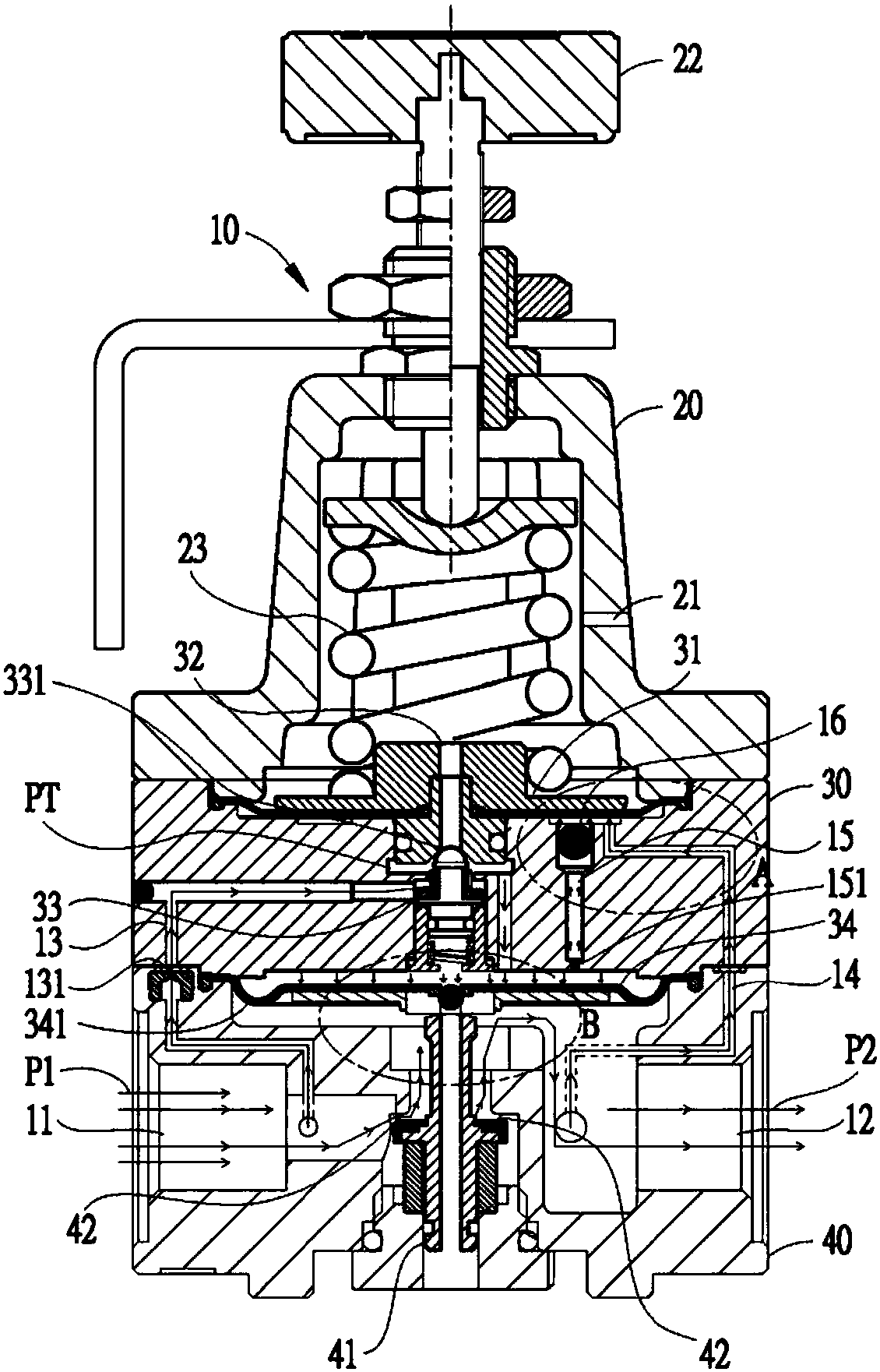

[0021] The present invention is an improved structure of an energy-saving precision pressure regulating valve, which has a body 10, which is provided with an input end 11 and an output end 12 for a pneumatic fluid P to enter and exit. Side pressure P1, secondary side pressure P2, its main body 10 is mainly composed of a pressure regulating air seat 20, a middle valve seat 30, and a base 40 connected from top to bottom, and the bottom of the pressure regulating air seat 20 and the middle valve seat There is also a balance diaphragm 31 between the 30, and a main diaphragm 34 is provided under the base and the middle valve seat 30, and the main diaphragm 34 is covered with a layer of diaphragm rubber 341;

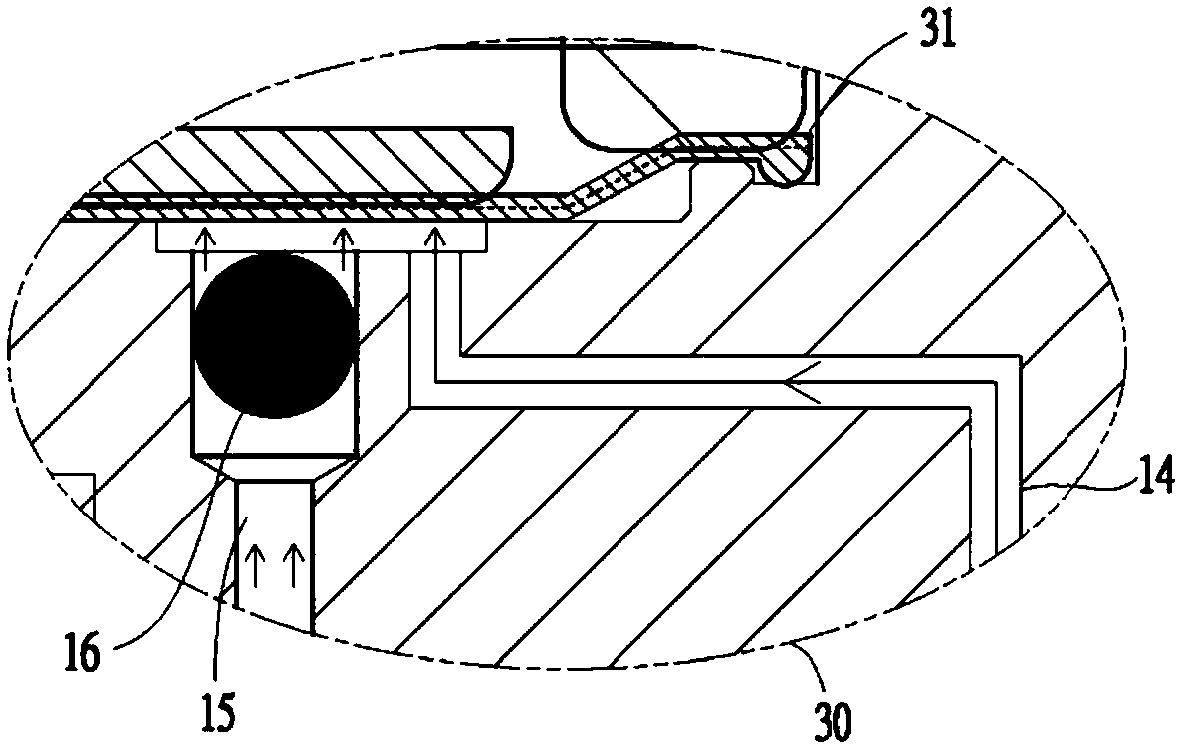

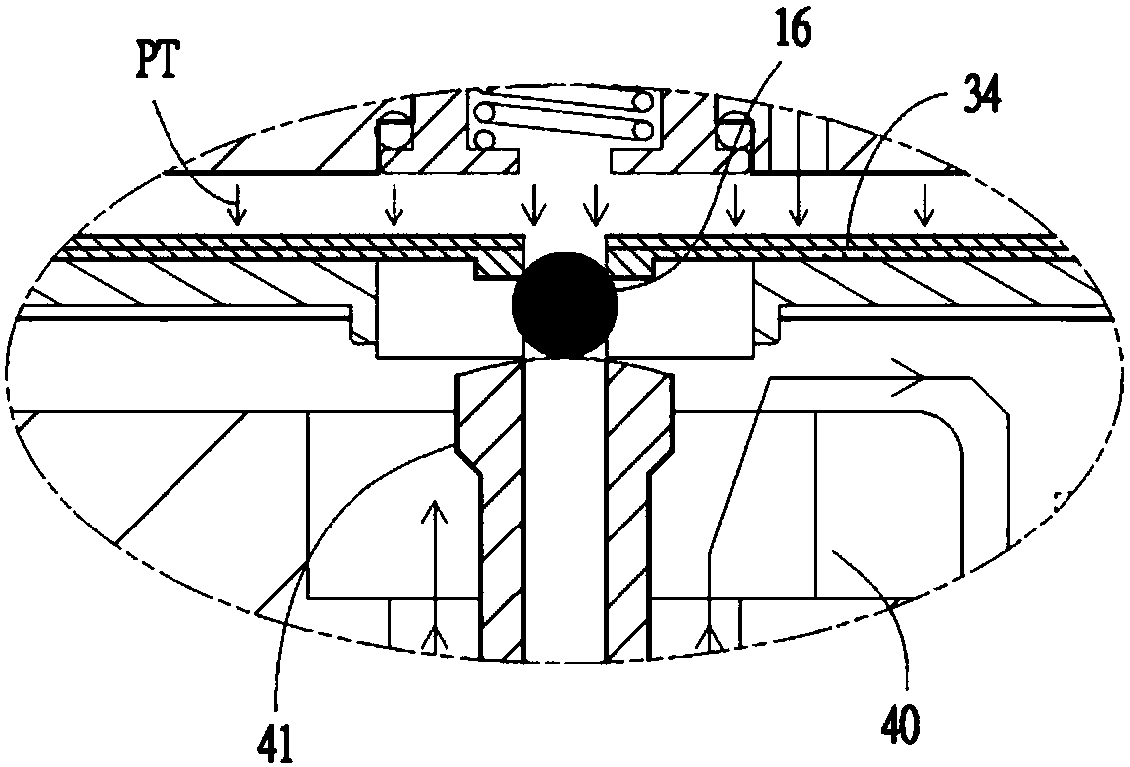

[0022] The inside of the middle valve seat 30 is further provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com