Method and device for liquefying low-boiling-point gas and recovering BOG (Boil Off Gas) of cryogenic vessel

A low-temperature container, low boiling point technology, applied in liquefaction, refrigeration, liquefaction, solidification and other directions, can solve the problems of complex structure, difficult operation, high operating cost, and achieve the effects of low system energy consumption, reliable operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

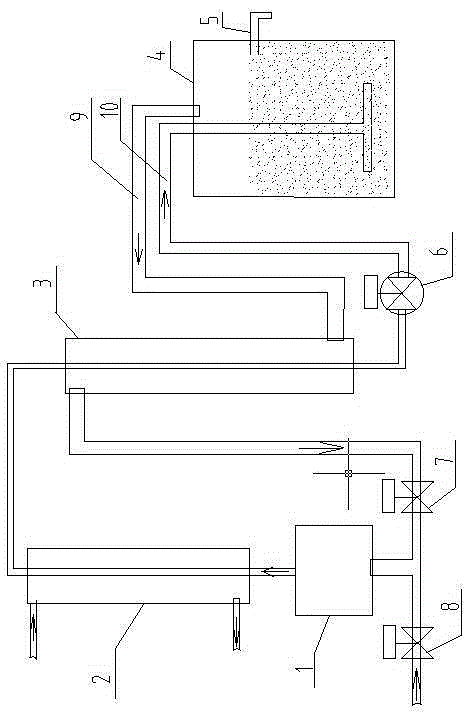

[0038] Example 1: Used in the liquefaction of natural gas.

[0039] see figure 1 , the compressor 1 is a normal temperature compressor; the conventional heat exchanger 2 is a water-cooled heat exchanger, and the shell side is cooling water; the subcooling heat exchanger 3 is a vertically installed tube-and-tube heat exchanger.

[0040] The medium-pressure high-temperature gas outlet of compressor 1 is connected to the tube-side inlet of conventional heat exchanger 2, and the tube-side outlet of conventional heat exchanger 2 is connected to the tube-side inlet of subcooling heat exchanger 3 (the tube-side inlet is located in the subcooling heat exchanger 3), the outlet of the tube side of the subcooling heat exchanger 3 is connected to the inlet of the throttling pressure reducer 6, and the throttling pressure reducer 6 uses a throttling control valve to reduce the outlet pressure to a lower pressure than that of the low temperature liquefaction storage tank 4 liquid The phase...

Embodiment 2

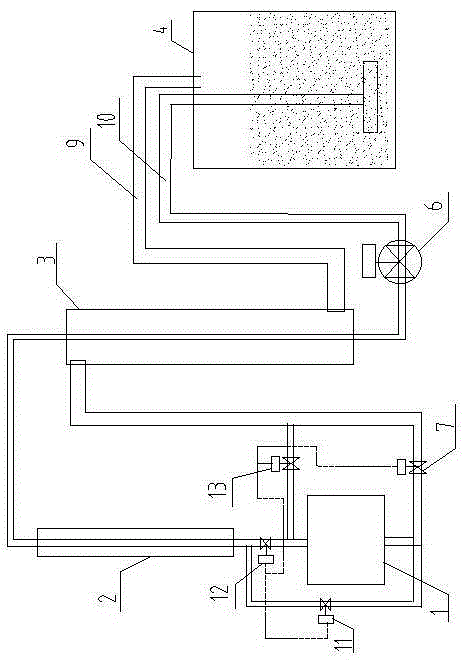

[0046] Example 2: BOG recovery for LNG storage tanks.

[0047] see figure 2 , the overall structure of the device is basically the same as that of Embodiment 1, the main difference being: no fresh air input, no fresh air control valve 8; There is an air flow pipeline connected between them and a first air flow control valve 11 is installed; a second air flow control valve 12 is installed at the air outlet of the compressor 1; An airflow pipeline is connected between the stroke outlets and a third airflow direction control valve 13 is installed.

[0048] Its basic working process is the same as that of Embodiment 1, mainly because the flow direction of the inlet and outlet airflow of compressor 1 can be switched, because this system is only used for the recovery and internal pressurization of the liquid evaporator gas (BOG) in the low-temperature liquefaction storage tank 4, Therefore, the overflow pipe 5 which plays a role in stabilizing the liquid level is also cancelled. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com