Electronic control electromagnetic relief valve with good sealing performance

A supercharger and sealing technology, which is applied in the field of electronically controlled electromagnetic pressure relief valves of superchargers, can solve the problems of increased leakage, easy deformation, and unsuitable control of leakage, and achieve rapid boosting or pressure relief , Improve adaptability and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

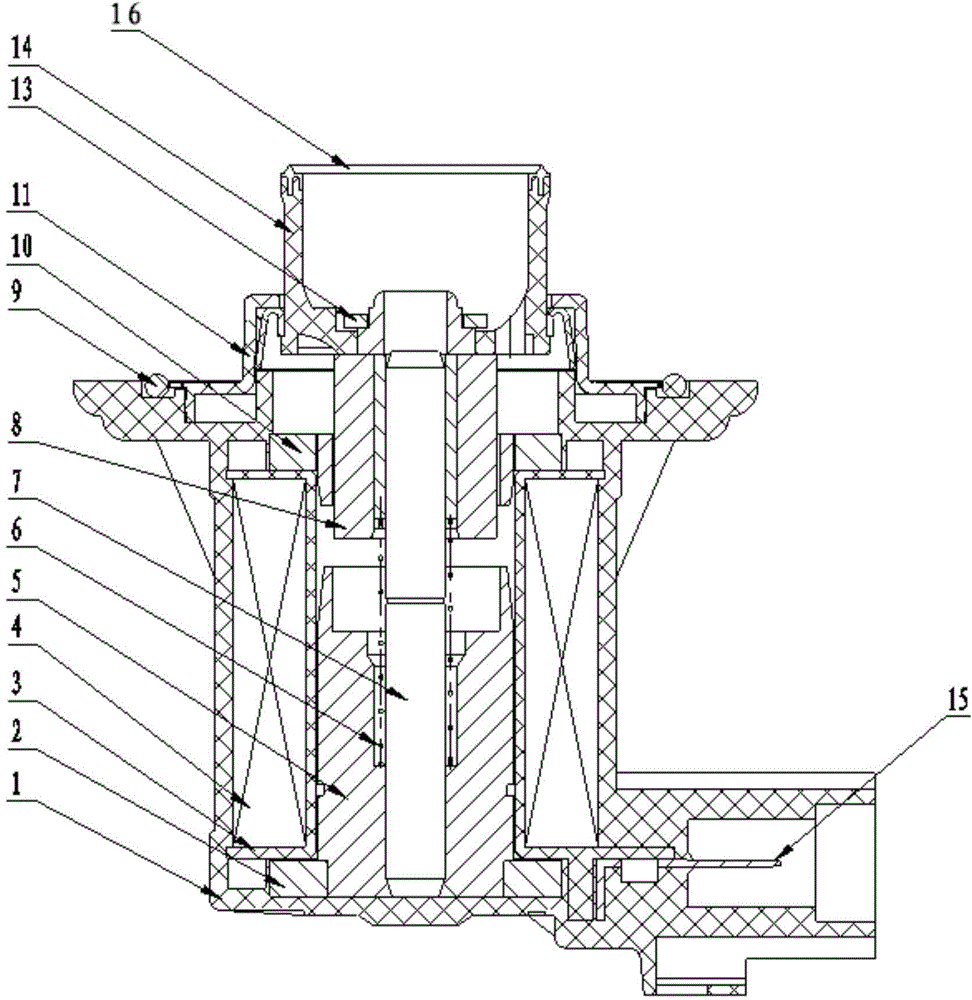

[0008] figure 1 As shown, it is a new type of electronically controlled electromagnetic pressure relief valve for a supercharger, including a valve body 1 with an electronically controlled socket 15 and a solenoid valve cover 11 sealed by an O-ring 9, and a static iron core is arranged at the bottom of the valve body 5. A magnetically conductive plate 2 is provided on the outer periphery of the bottom of the static iron core 5, and a wire frame 3 is arranged on the upper part of the magnetically conductive plate 2, and a coil winding 4 wound on the static iron core 5 is arranged on the upper part of the wire frame 3; the valve body 1 The top of the moving iron core 8 is provided with a moving iron core 8 corresponding to the static iron core 5, the top of the moving iron core 8 is fixedly connected with the sealing cover 14 through the moving iron core washer 13, and the middle outer edge of the moving iron core 8 is provided with a guide The magnetically conductive cover plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com