Intelligent and automatic assembly production line for electric cookers

An assembly line and rice cooker technology, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of non-standard assembly, large human resource costs, and low assembly efficiency, so as to improve product quality, reduce human resource costs, The effect of improving assembly productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

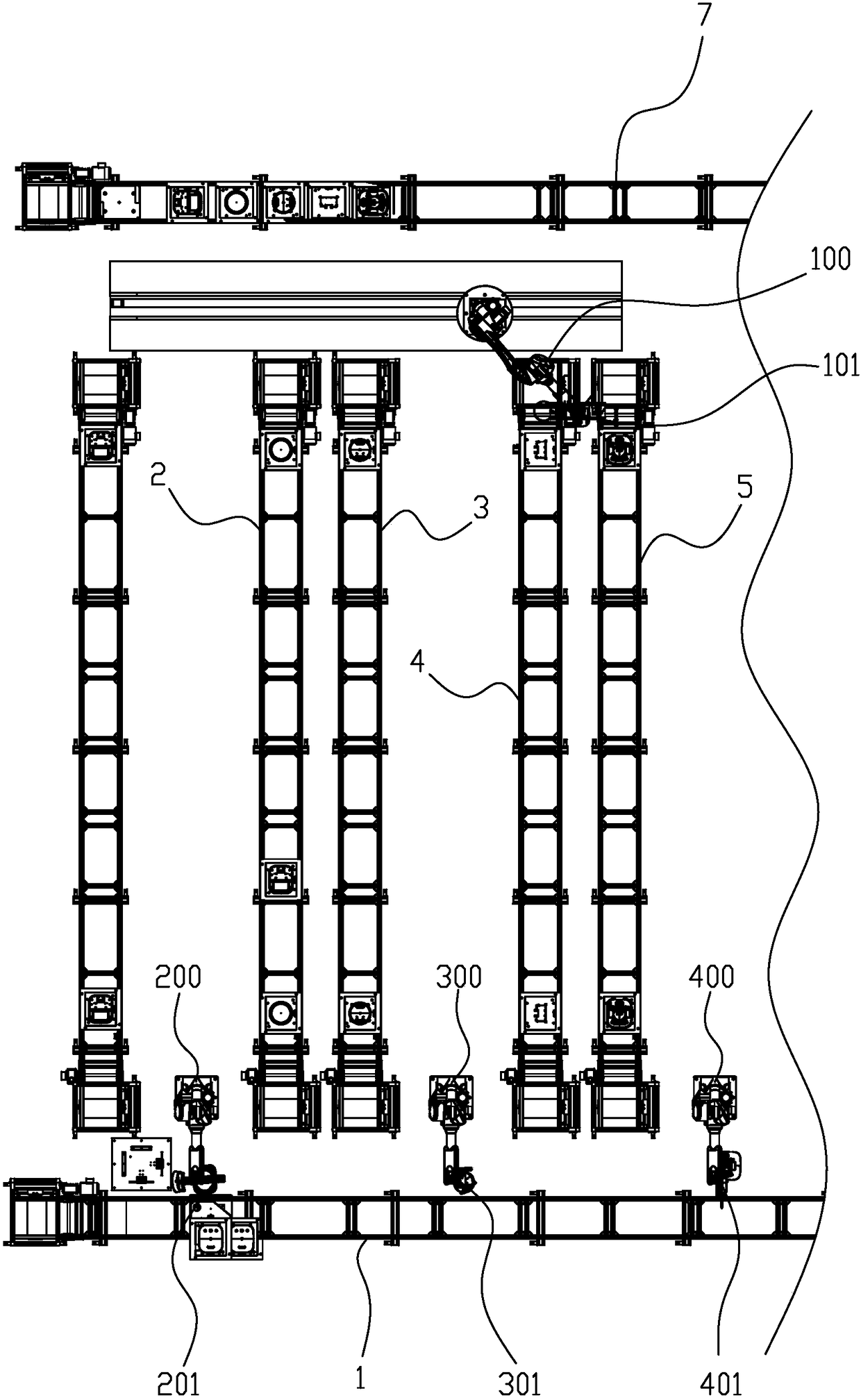

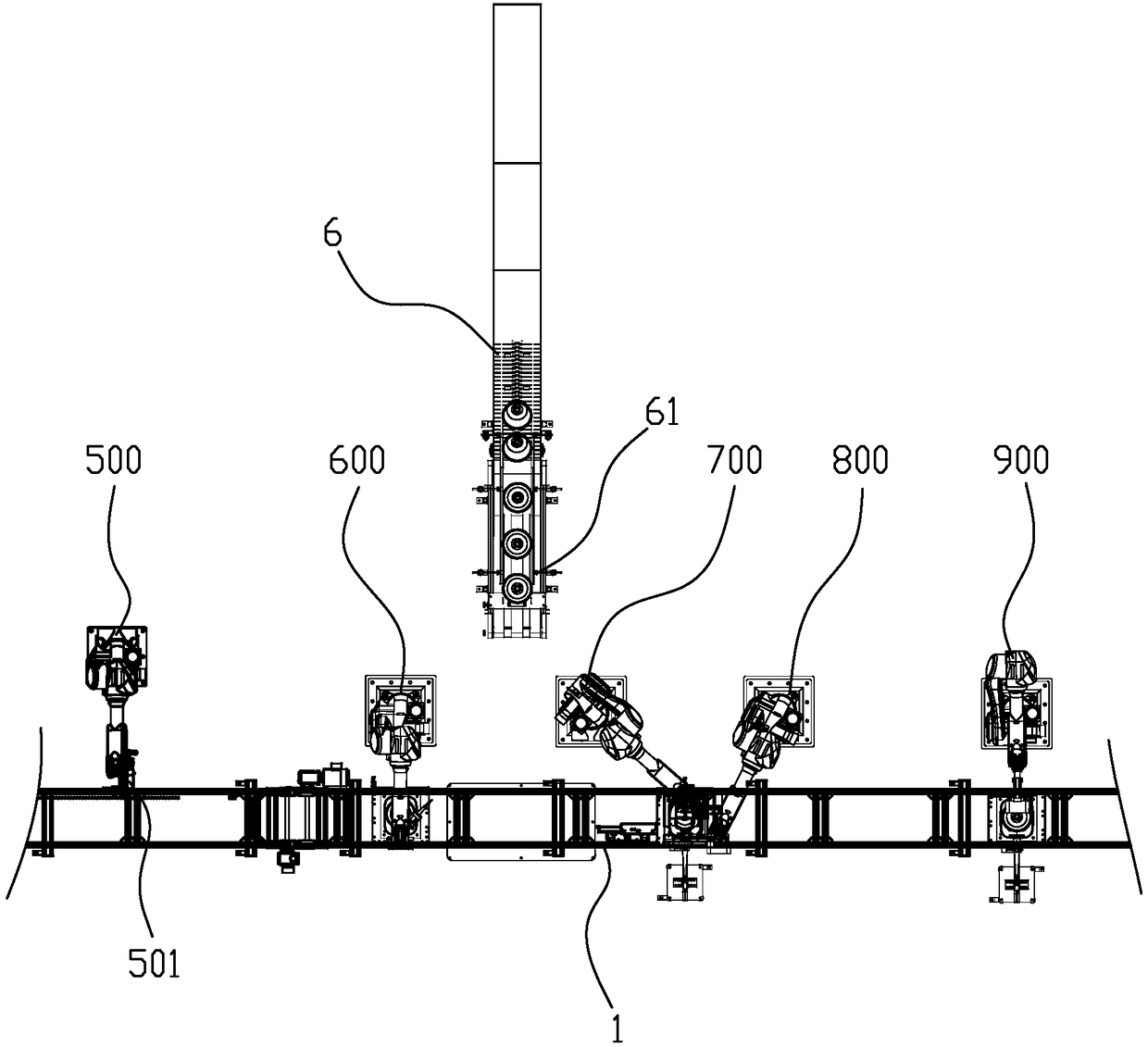

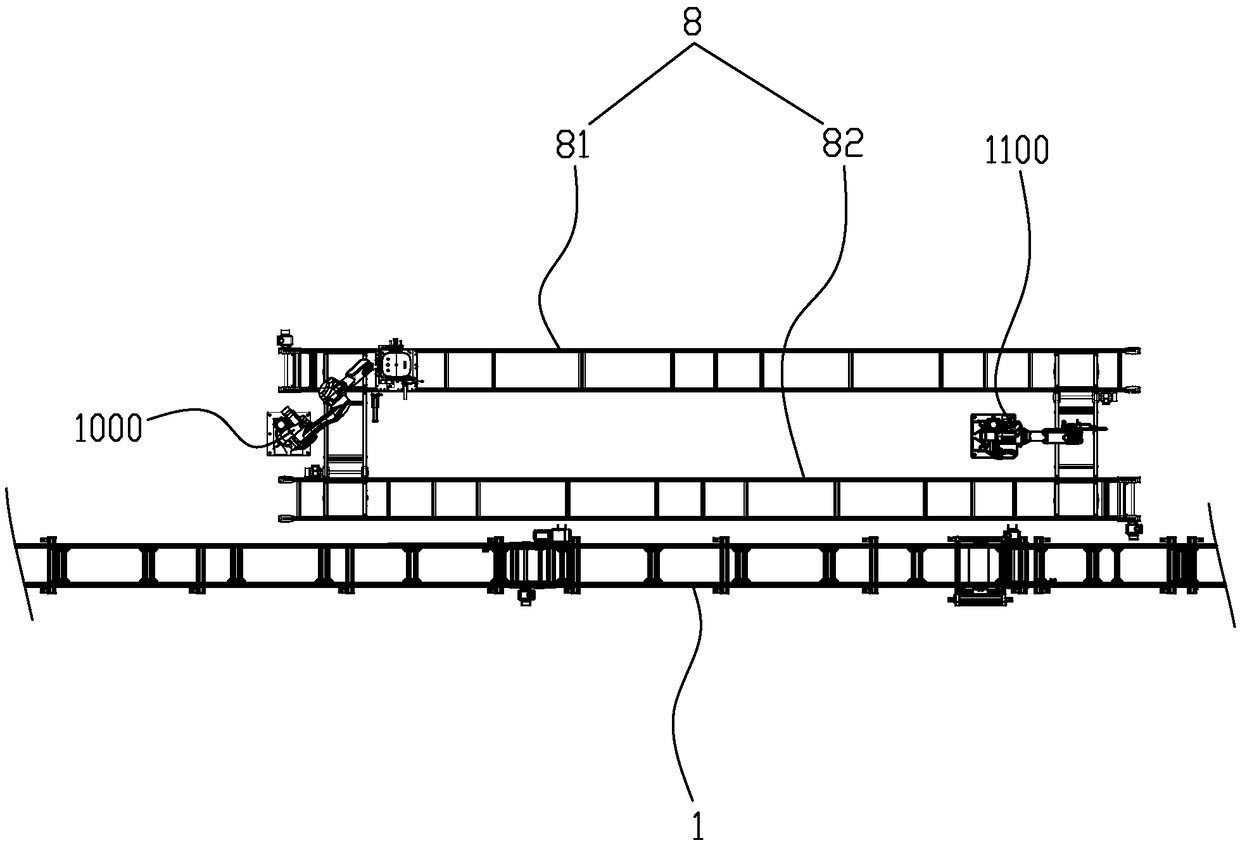

[0026] The intelligent automated assembly production line for rice cookers as shown in the figure includes a main conveyor line 1, and also includes a second robot 200, a third robot 300, and a fourth robot 400 that are sequentially arranged on one side of the main conveyor line 1 according to the assembly process. The fifth robot 500 and the seventh robot 700. The second robot 200 is used to transport the rice cooker upper cover assembly to the main conveyor line 1, and the third robot 300 is used to install the rice cooker heating plate assembly and the rice cooker power supply board assembly to the main conveyor line 1 from the second On the rice cooker upper cover assembly from the second robot 200, the fourth robot 400 is used to fix the rice cooker heating plate assembly and the rice cooker power board assembly on the main conveyor line 1 on the rice cooker upper cover assembly and install the rice cooker base To the rice cooker upper cover assembly that is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com