Zero frame suspended liquid crystal display equipment and assembly method thereof

A liquid crystal display and zero-frame technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as the inability to realize a frameless full-screen design, achieve screw-free optimization of the module appearance, improve assembly efficiency, and simplify assembly difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

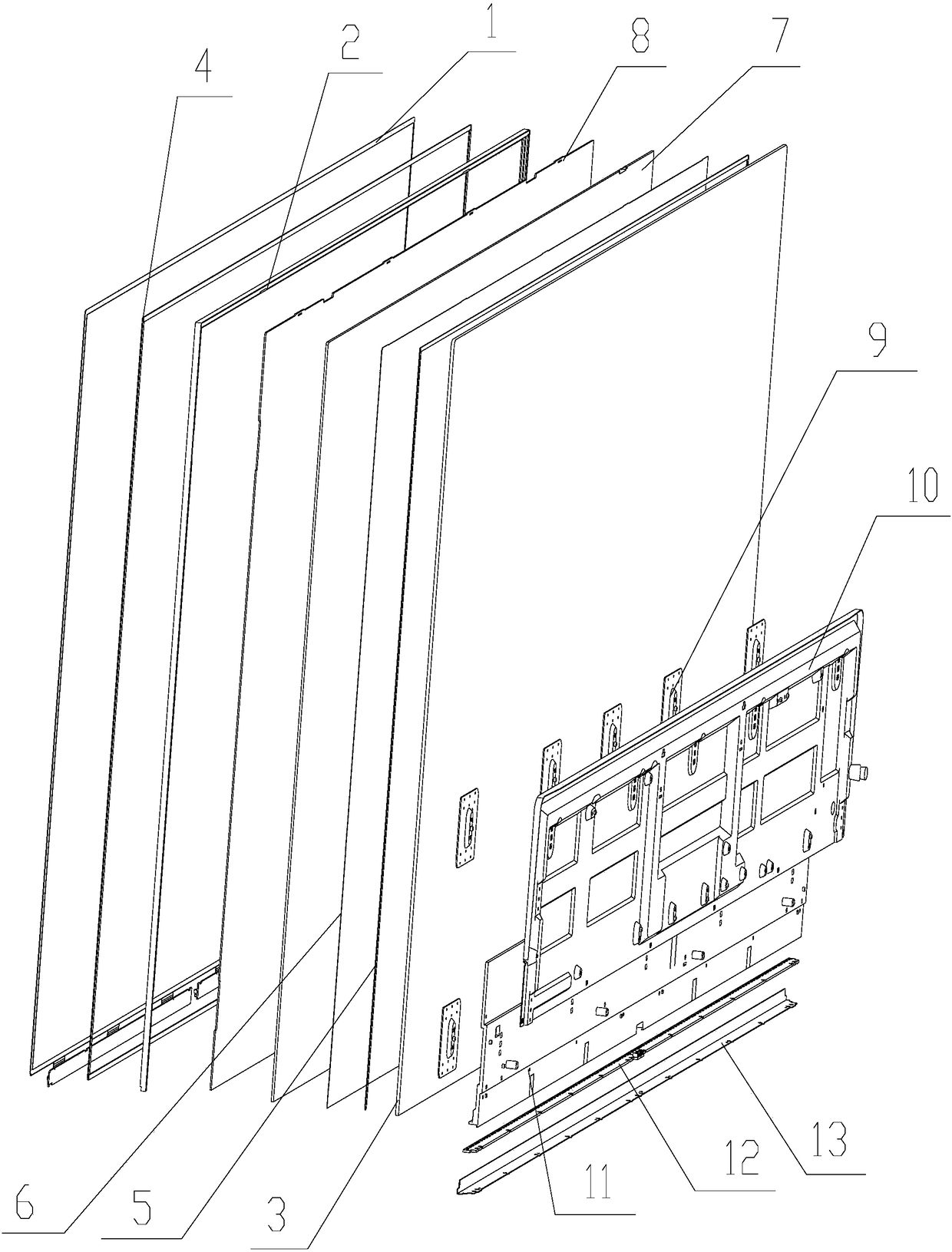

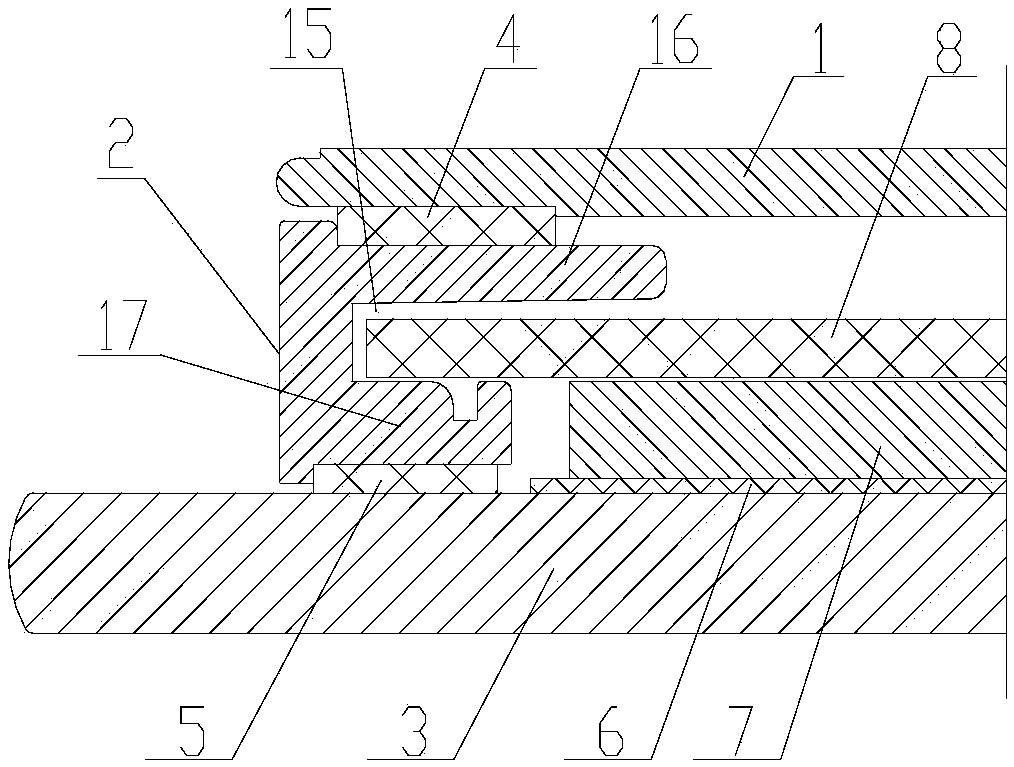

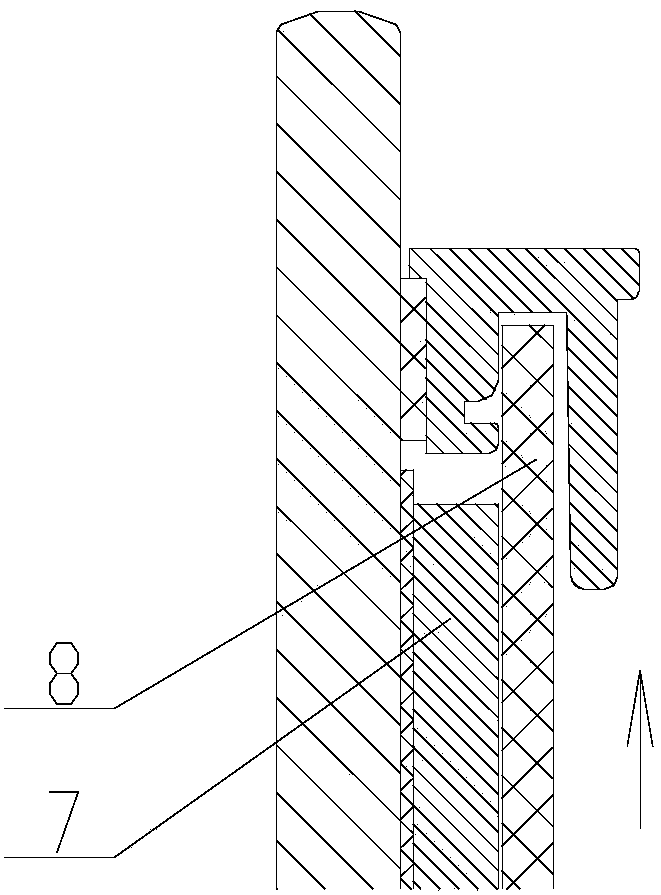

[0029] Such as figure 1 , 2 As shown in and 4, the zero-frame floating liquid crystal display device of the present invention includes a display screen 1, a casing and a backlight module, wherein the casing includes a face frame 2 and a backplane 3, and the backlight module includes a reflector 6, a light guide plate 7, The optical film 8 and the light bar 12 are bonded to the rear side of the back plate 3 with a plurality of fixed blocks 9. The fixed blocks 9 are used to transfer and fix the light bar radiator 11 and the movement fixed plate 10. The fixed blocks 9 are distributed in multiple points. The flatness accuracy requirements of the parts and the cost of the parts are fixed and reduced, so as to ensure the flatness of the heat sink 11 of the light bar and the assembly accuracy of the light bar. For example figure 1 As shown, there are ten fixed blocks 9 in two r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com