Operation control method and device of execution mechanism

An actuator and operation control technology, applied in the direction of motor control, feedback control, control system, etc., can solve the problems of inaccurate position operation, continuous adjustment of position, and time-consuming, etc., to achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

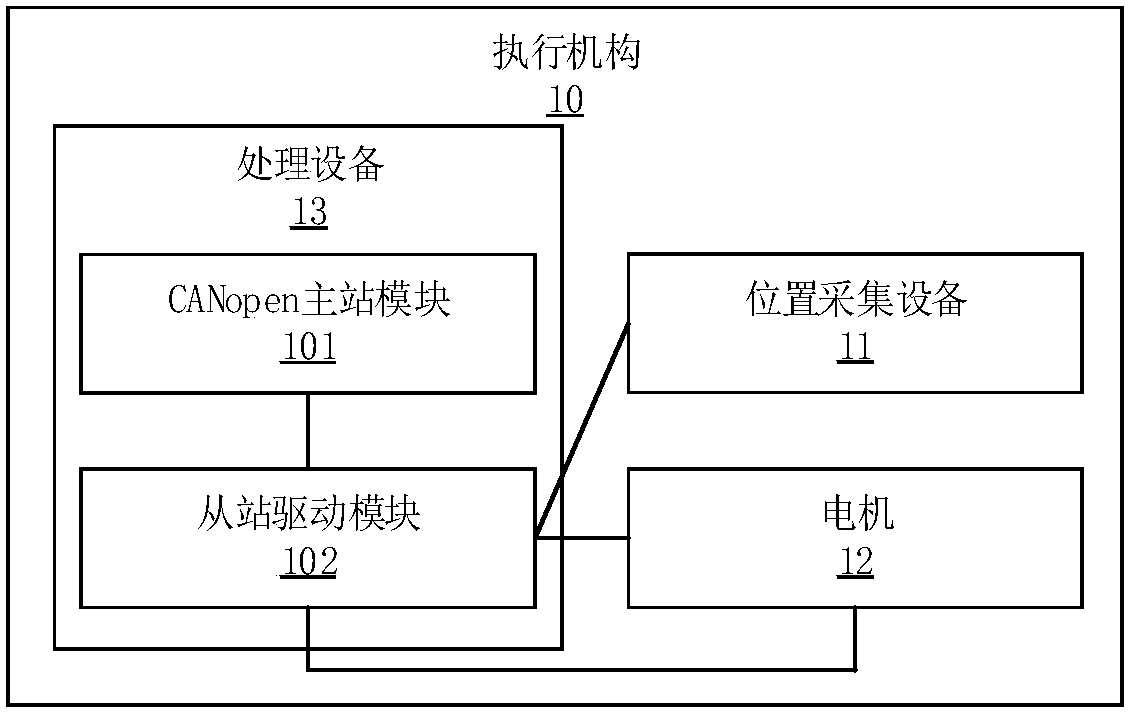

[0028] see figure 1 , the first embodiment of the present invention provides an actuator 10 , the actuator 10 includes: a position acquisition device 11 , a motor 12 and a processing device 13 . Wherein, the processing device 13 is electrically connected to the position acquisition device 11 and the motor 12 respectively.

[0029] The position collection device 11 is a conventional distance sensor, for example, the position collection device 11 may be a laser or an infrared distance sensor. The motor 12 is a conventional synchronous or asynchronous motor. Data interaction is performed between the position acquisition device 11 and the motor 12 and the processing device 13 .

[0030] The processing device 13 is an integration of various modules, that is, the processing device 13 may include: a CANopen master module 101 and a slave driver module 102 . Wherein, the CANopen master module 101 is connected with the slave driver module 102, and the slave driver module 102 is elect...

no. 2 example

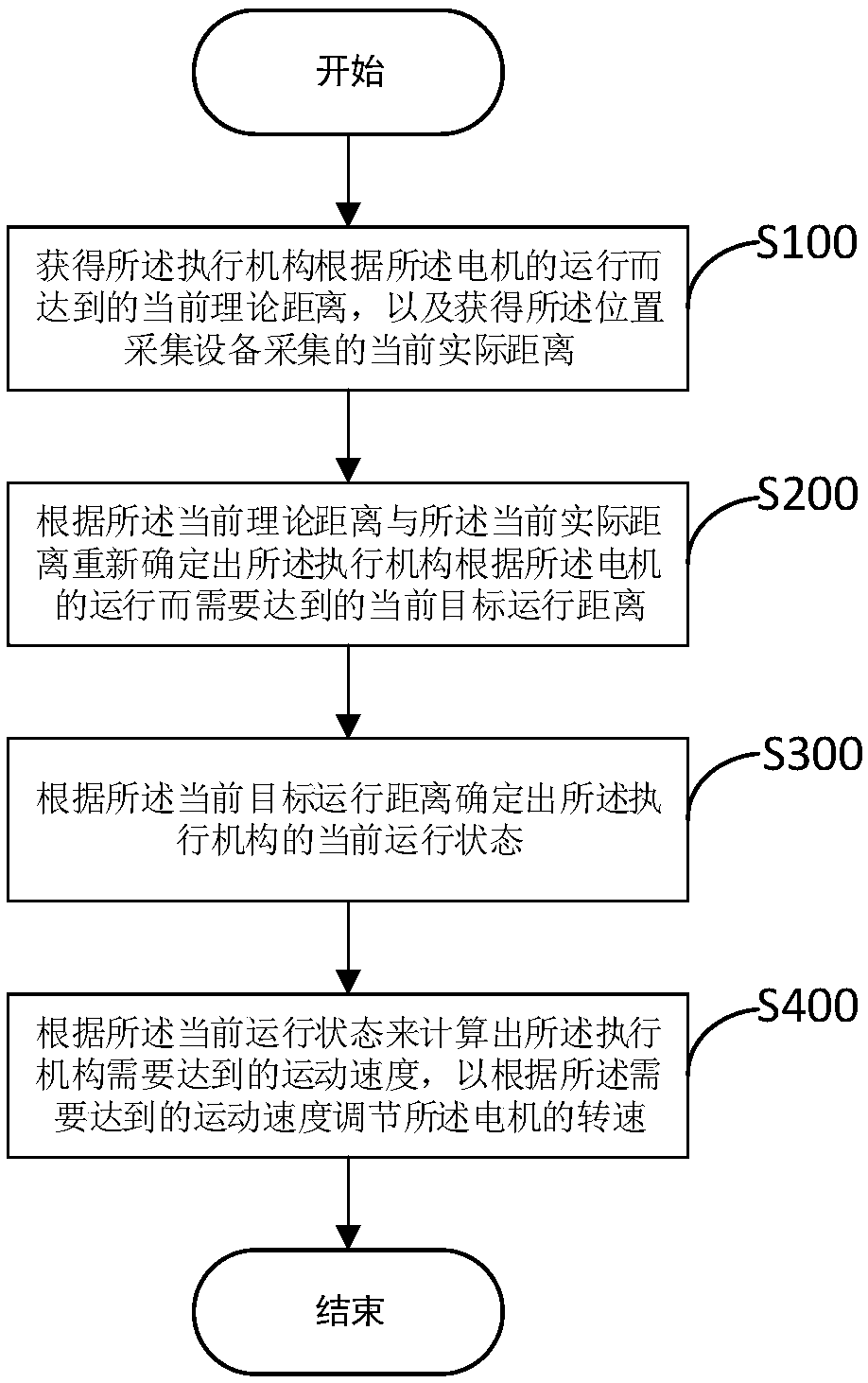

[0032] see figure 2 , the second embodiment of the present invention provides an operation control method of an actuator, and the operation control method of the actuator is applied to a processing device of the actuator. The operation control method of the actuator includes: step S100, step S200, step S300 and step S400.

[0033] Step S100: Obtain the current theoretical distance reached by the actuator according to the operation of the motor, and obtain the current actual distance collected by the position collection device.

[0034] During the process of the actuator moving on the corresponding track according to the control of the processing device, the processing device realizes the control of the motion of the actuator through a plurality of continuous control cycles. In this embodiment, the operation control method of the actuator is described in detail by using the processing device to execute any one of the multiple control cycles. Wherein, the control of the proce...

no. 3 example

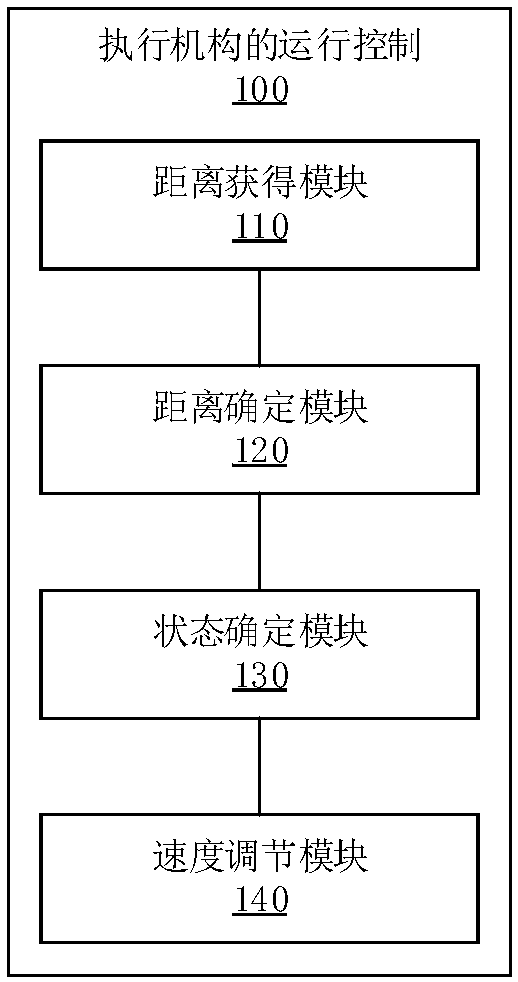

[0060] see image 3 , the third embodiment of the present invention provides an operation control device 100 of an actuator, the operation control device 100 of the actuator is applied in the processing equipment of the actuator, and the operation control device 100 of the actuator includes:

[0061] The distance obtaining module 110 is configured to obtain the current theoretical distance reached by the actuator according to the operation of the motor, and obtain the current actual distance collected by the position collection device.

[0062] The distance determination module 120 is configured to re-determine the current target running distance that the actuator needs to achieve according to the operation of the motor according to the current theoretical distance and the current actual distance.

[0063] A state determining module 130, configured to determine the current running state of the actuator according to the current target running distance.

[0064] The speed adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com