Ceramic insulator provided with heat absorbing and ice melting device

A porcelain insulator and ice-melting technology, which is applied in the field of porcelain insulators, can solve the problems of increasing the occupied area of line corridors, air gap breakdown, and high cost of renovation, and achieve the effect of simple structure, changing flashover tripping, and keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

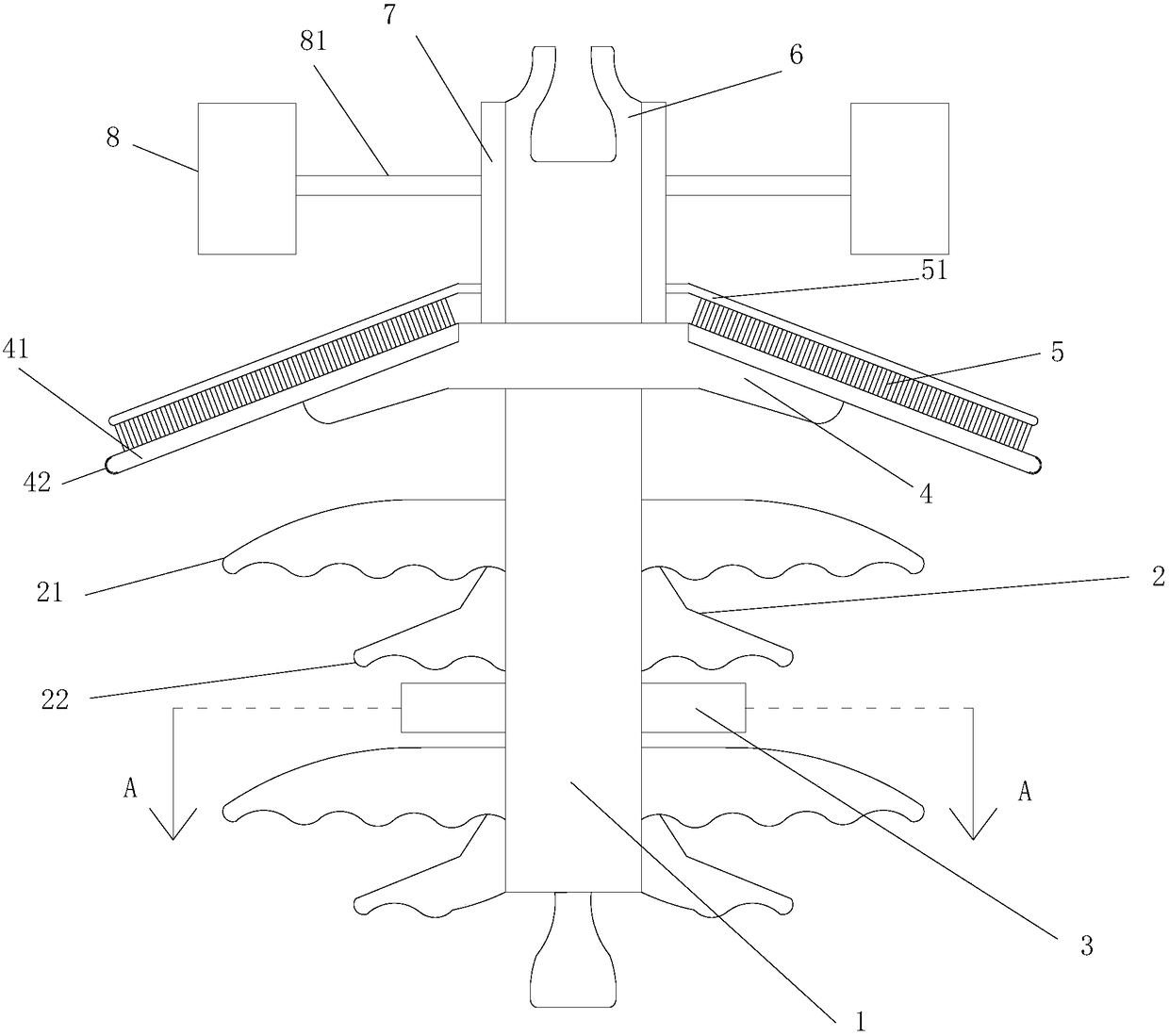

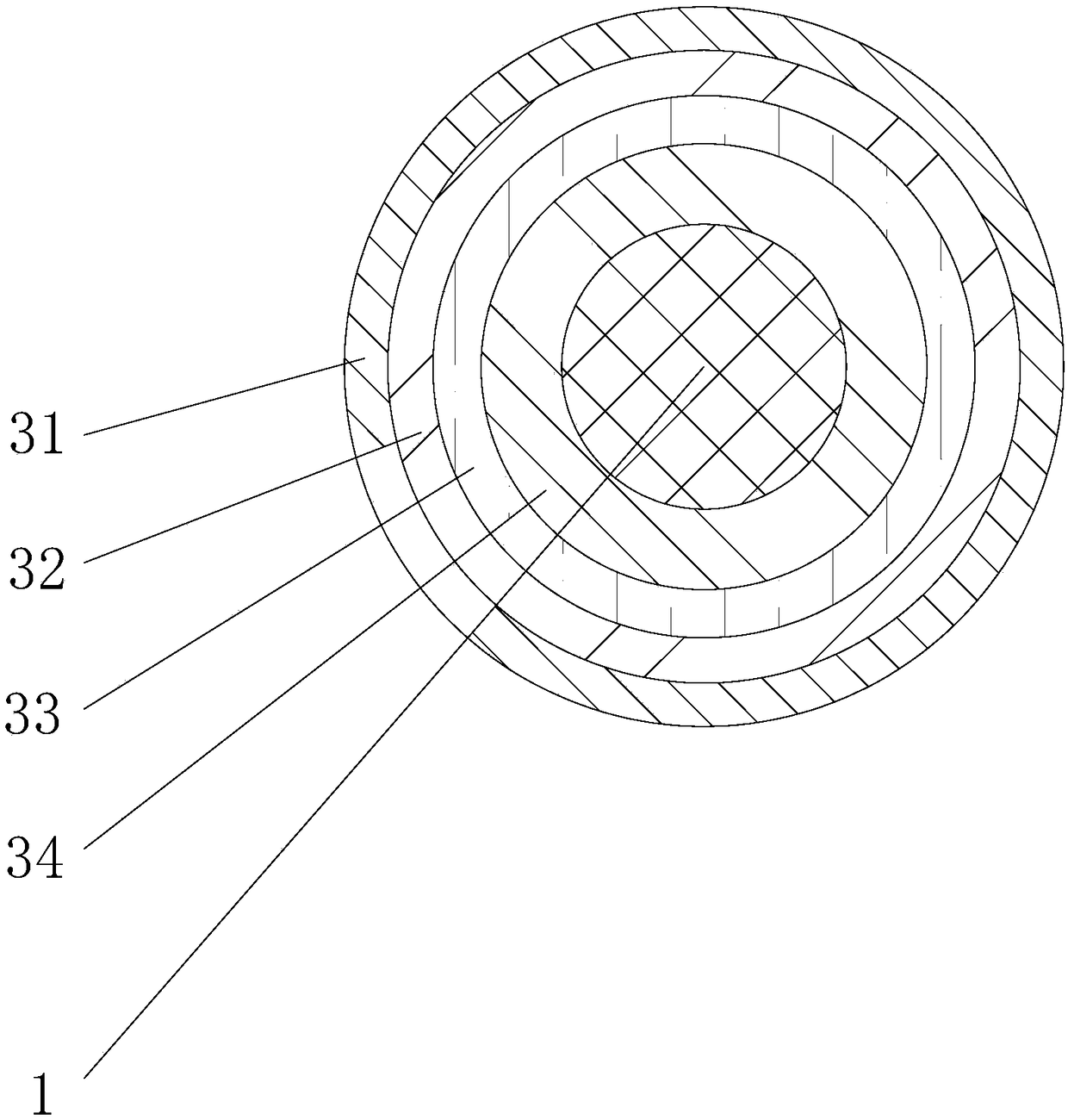

[0013] like Figure 1-Figure 2 Shown: a porcelain insulator with a heat-absorbing and ice-melting device, including a mandrel 1, an umbrella skirt group 2 covering the outside of the mandrel 1, a heat-absorbing and ice-melting device 3, a supporting block 4, fixed on the supporting Drip eaves 41, connecting rod 51, brush plate 5, steel cap 6, bearing 7, fan blade 8 and extension rod 81 at block 4 tops. The outer side of the mandrel 1 is provided with a steel cap 6, a supporting block 4, an umbrella skirt group 2, and a heat-absorbing and ice-melting device 3 from top to bottom, the bearing 7 is arranged on the outer side of the steel cap 6, and the fan blade 8 The brush plate 5 is fixed on the lower end of the bearing 7 through the connecting rod 51 through the extension rod 81 and fixed on both sides of the bearing 7 . The shed sets 2 are evenly spaced on the mandrel 1 , and the heat-absorbing and ice-melting device 3 is set between adjacent shed sets 2 . The heat-absorbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com