Detection equipment for mobile phone parts

A technology for testing equipment and parts, applied in the field of testing equipment, can solve the problems of low work efficiency, low testing accuracy, and high production cost, and achieve the effects of fast running speed, high testing accuracy, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

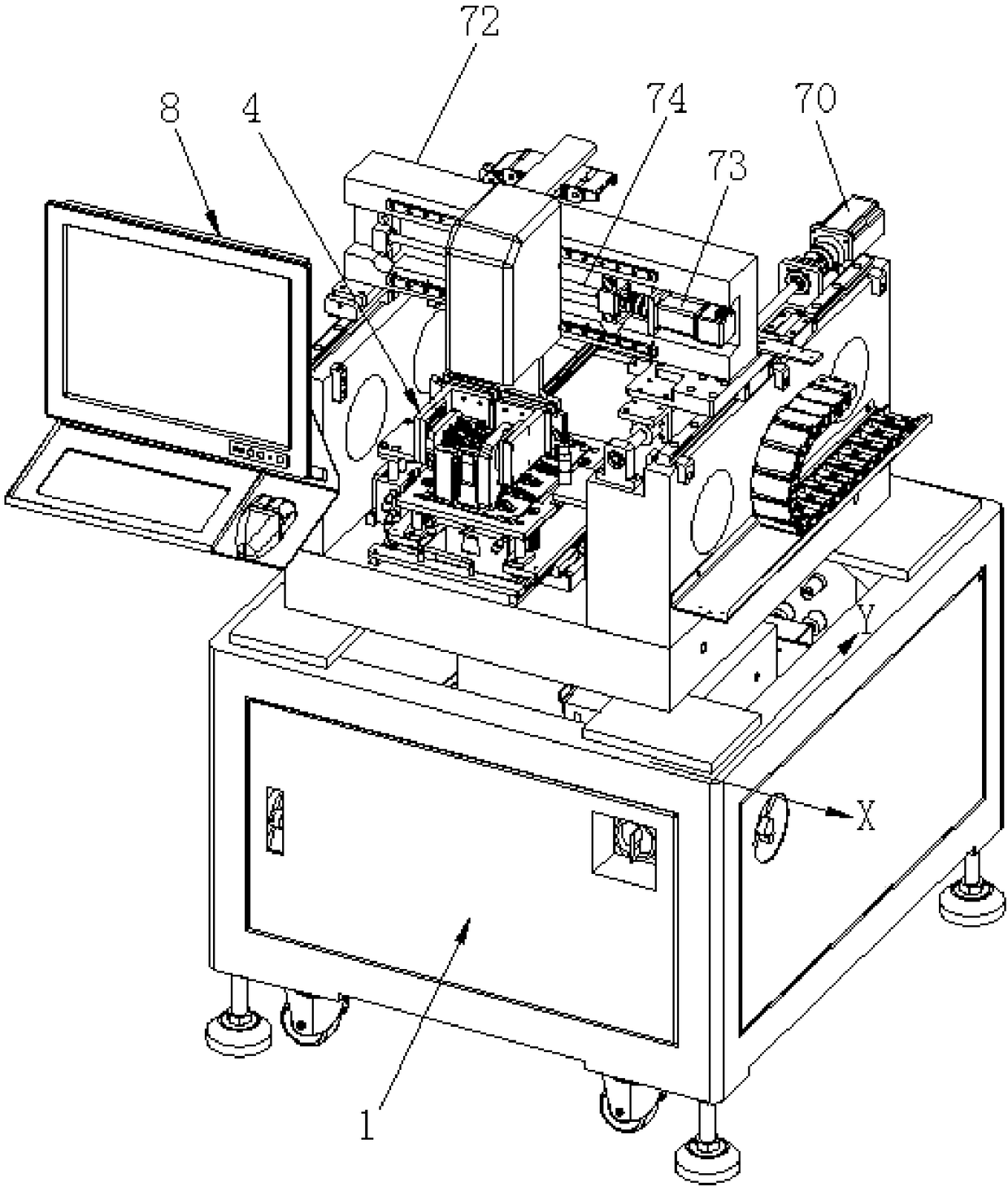

[0038] Please refer to the attached figure 1 As shown, it is a three-dimensional structural schematic diagram of the mobile phone component testing equipment of the present invention. The mobile phone parts testing equipment includes a base box 1, a carrier 2 for receiving mobile phone parts, a positioning mechanism 3, a detection module 4 for detecting mobile phone parts, and a power mechanism, wherein the A horizontal working platform is arranged on the top side of the base box 1, and the carrier 2 is movably arranged on the horizontal working platform, and the carrier 2 can also be relatively positioned under the action of the positioning mechanism 3. The position of the horizontal working platform is fixed; the detection module 4 is arranged on the top of the horizontal working platform, and the detection module 4 can also be moved under the drive of the power mechanism to be opposite to the load The mobile phone parts on tool 2 are detected.

[0039] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com