Ceramic heating body automatic sorting device

A ceramic heating element and automatic sorting technology, which is applied in the field of industrial machinery, can solve the problems of low sorting efficiency, error-prone, and low productivity, and achieve the effects of increasing automation, simple feeding, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

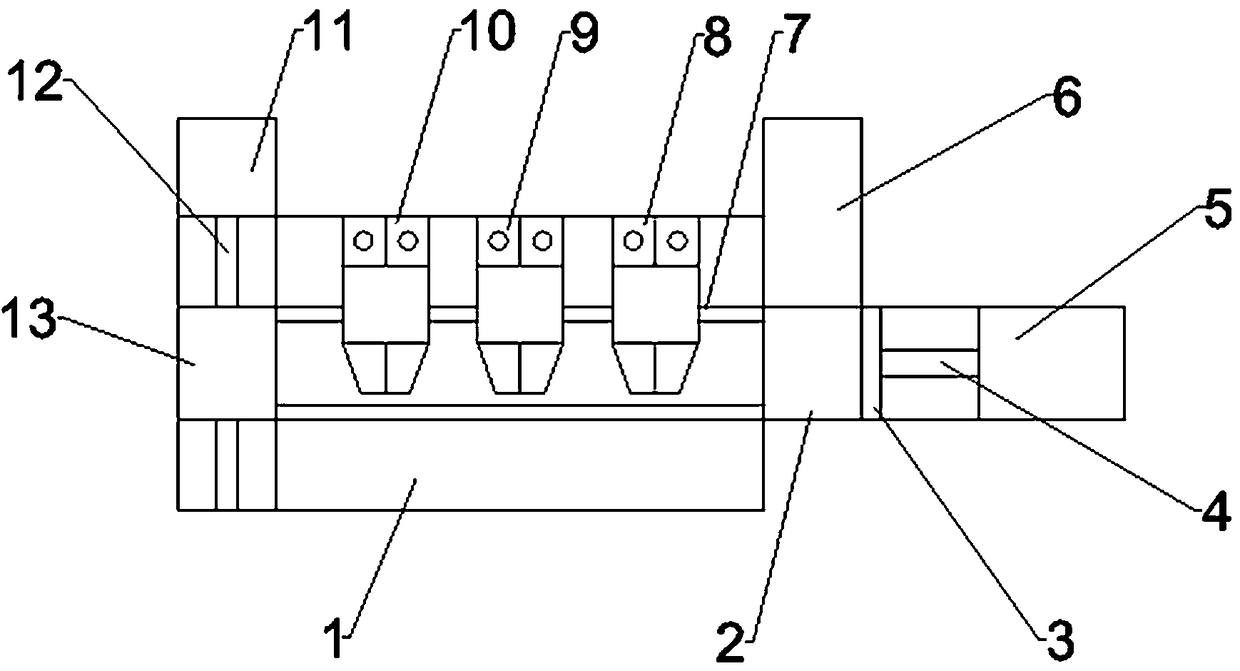

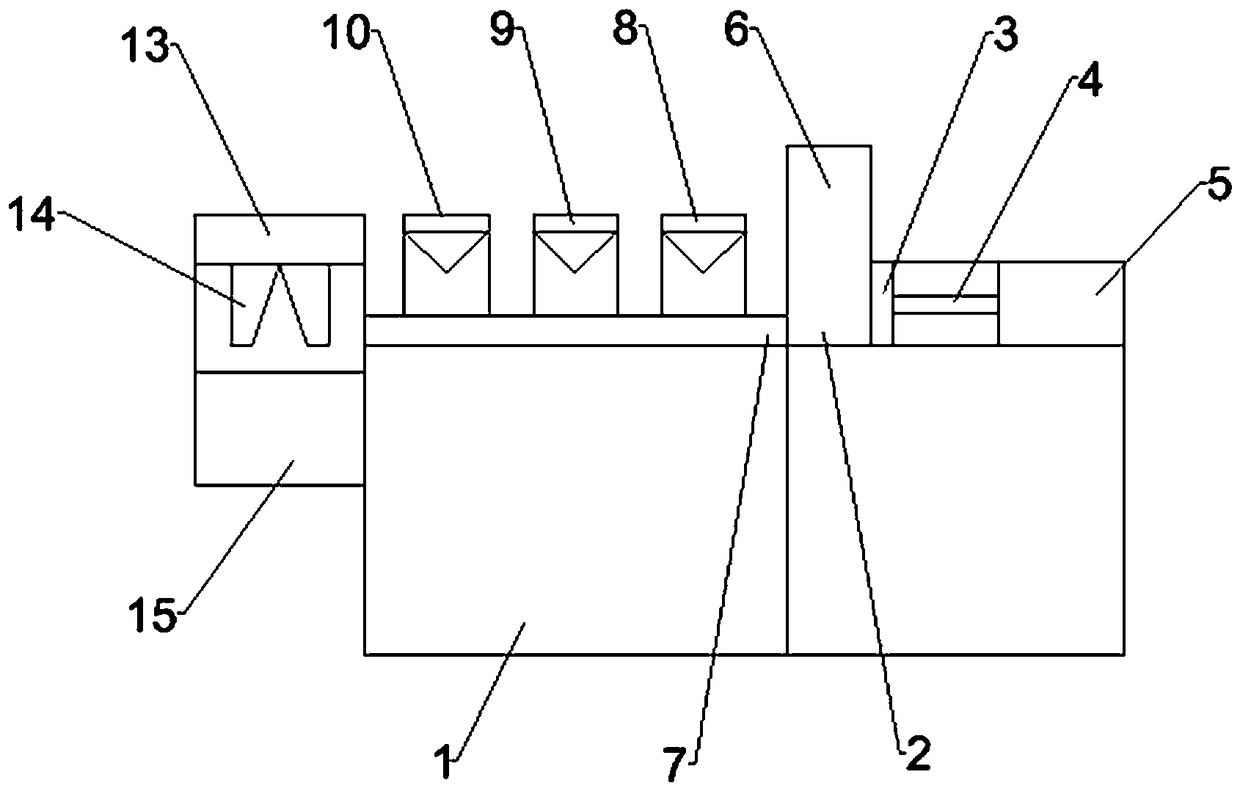

[0021] First turn on the power supply, put the fixture equipped with ceramic heating element into the slideway 6, slide into the propulsion chamber 2 by gravity, and push the pneumatic push plate 3 by the propulsion motor 5 to push the fixture equipped with ceramic heating element to the In the transfer guide rail 7, the transfer guide rail 7 is used to sequentially detect the clamps equipped with ceramic heating elements and transport them to the bottom of the clamping frame 14. After the resistance of the ceramic heating element is determined through the detection information, the clamping motor 13 controls the clamping frame 14 to clamp The clamp with the ceramic heating element is housed, and moves along the direction of the guide bar 12 to the top of the 15 grid slots of the sorting box, unclamps the clamping frame 14 and puts the clamp with the ceramic heating element into the sorting box 15 and gets final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com