Automatic assembly equipment for pressure stabilizing valve

A technology of automatic assembly and pressure stabilizing valve, which is applied in metal processing equipment, assembly machines, metal processing, etc., can solve the problems of manufacturers' cost pressure, troublesome manual operation, and unstable quality, so as to reduce labor costs, improve productivity, The effect of convenient follow-up maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

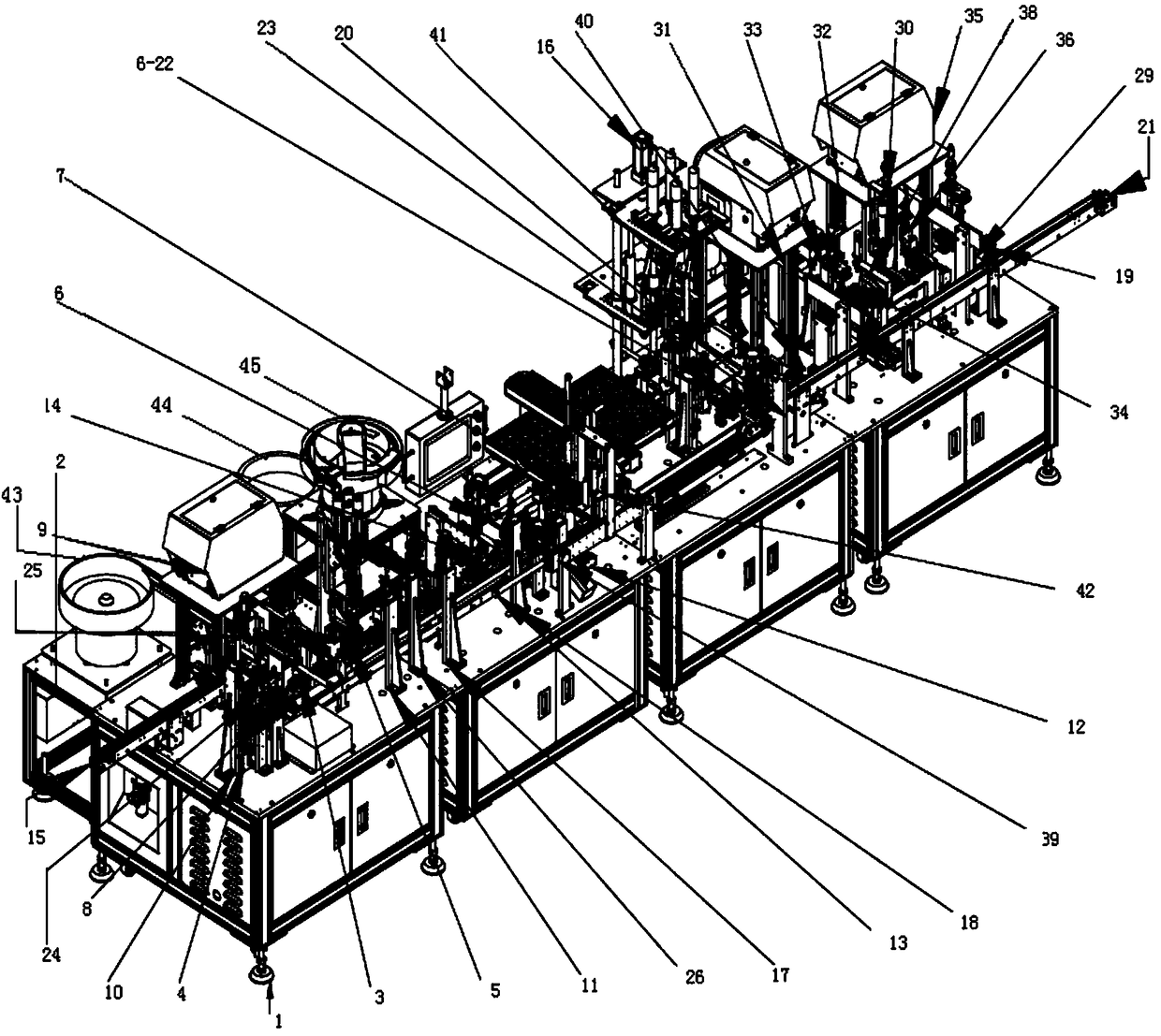

[0023] figure 1 , 3 As shown in , 4, the automatic assembly equipment of the pressure stabilizing valve includes the frame components and necessary supporting devices to ensure the normal operation of the overall equipment, and also has a shell feeding mechanism, a spring feeding mechanism, a shell unloading mechanism, an upper bottom cover and The bottom cover locking mechanism, the touch screen assembly, the shell loading mechanism, the spring loading mechanism, the casing unloading mechanism, the upper bottom cover and the bottom locking mechanism, and the touch screen assembly are installed on the frame assembly 1 .

[0024] figure 1 As shown in , the shell feeding mechanism includes an outer cover screw detection mechanism 11, a screw feeder 9, an outer cover vibrating plate 43, an outer cover locking screw mechanism 5, an outer cover feeding mechanism 2, a shell grasping mechanism 8, and Forming tooling 4, feeding conveyor belt 15, outer cover locking screw mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com