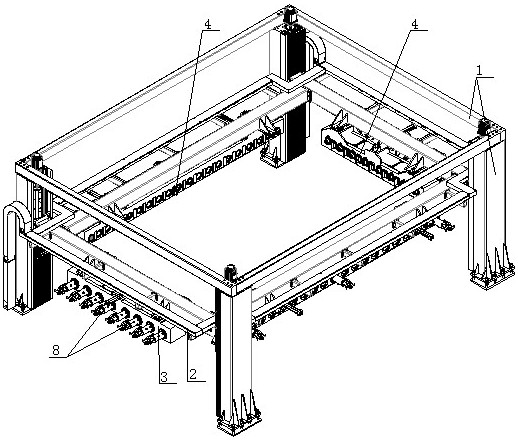

Prestressed track slab reinforcement tensioning machine

A tensioning machine and track plate technology, applied in ceramic molding machines, manufacturing tools, etc., can solve problems such as inability to achieve fast and accurate clamping, decline in the production quality of track plates, and inconsistent prestressing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

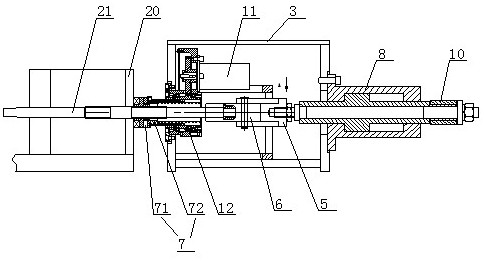

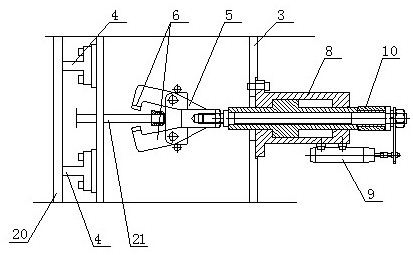

[0024] Such as Figure 8 As shown, the applicant has made a kind of track plate mold 20 in order to produce prestressed track plate, and its basic structure is identical with the track plate mold in the prior art, and this track plate mold has mold cavity, and the structure in this mold cavity And the shape is all in order to make the prestressed track slab, and its specific structure will not be repeated one by one. On the side wall of the track slab mold 20, a tension rod 21 is inserted, and the end of the tension rod is provided with a special-shaped nut 211, which can be used by a wrench. The tension rod is screwed by means of manual or manual methods, so as to realize the combination of the end of the steel bar and the tension rod. The existing equipment cannot realize the fast and accurate clamping of the tension rod, so the tension efficiency is low and the quality is poor. The tension rod 21 The middle part is also provided with a threaded section exposed to the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com