Chelating resin, pretreatment method, precious metal removal method, and precious metal catalyst removal method in unsaturated copolymer hydrogenation liquid

A technology of chelating resin and pretreatment liquid, which is applied in the field of hydrogenation of unsaturated copolymers, can solve the problems of secondary pollution of products, long time required to remove precious metal catalysts, etc., and achieve the effect of reducing the removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-1

[0107] This preparation example is used to illustrate hydrogenation catalyst M p x m L n The production method of (P1), wherein M is rhodium, X is chlorine, L is triphenylphosphine, p is 1, m is 1, and n is 3.

[0108] 4.5 g PPh 3 Dissolve in hot ethanol solution at 70°C under the protection of argon, and add the dissolved solution into the reaction flask; weigh 0.75 g of RhCl 3 ·H 2 O was dissolved in ethanol solution under the protection of argon, heated to reflux at 78°C, and RhCl 3 ·H 2 The ethanol solution of O was added dropwise into the reaction flask to react for 2.5 hours, cooled to 25°C, filtered with suction, washed with ether to obtain a powder catalyst for hydrogenation.

preparation example 1-2

[0110] This preparation example is used to illustrate hydrogenation catalyst M 1 a m 2 b x c L d (P2) preparation method, wherein, M 1 for rhodium, M 2 is ruthenium, X is chlorine, L is triphenylphosphine, a:b:c:d=2:1:4:9.

[0111] 4.5 g PPh 3 Dissolve in hot ethanol solution at 70°C under the protection of argon, and add the dissolved solution into the reaction flask; weigh 0.5 g of RhCl 3 ·H 2 O and 0.23 g RuCl 3 ·H 2 O was dissolved in ethanol solution under the protection of argon, heated to reflux at 78°C, and RhCl 3 ·H 2 O and RuCl 3 ·H 2 The ethanol solution of O was added dropwise into the reaction flask to react for 2.5 hours, cooled to 25°C, filtered with suction, and washed with ether to obtain a powdered Rh:Ru=2:1 catalyst for hydrogenation.

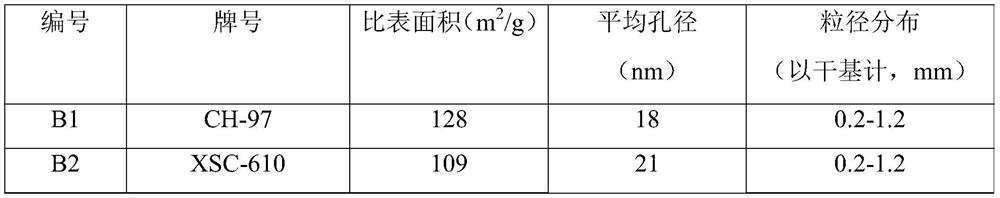

[0112] The physical parameters of the chelating resin styrene-divinylbenzene copolymer adopted in the embodiment 1-21 are shown in Table 1.

[0113] Table 1

[0114]

[0115]

[0116] The hydrogenated b...

Embodiment 1-19

[0127] (1) Soak the chelating resin styrene-divinylbenzene copolymer in the pretreatment liquid I at a'°C, the duration of soaking is b' hours, and then filter to obtain the chelate processed by the pretreatment liquid I Resin, then the gained chelating resin is soaked in the pretreatment liquid II, the soaking duration at i'°C is c' hour, filters to obtain the pretreated chelating resin, wherein, the pretreatment liquid I, the pretreatment liquid II and the volume ratio of chelating resin styrene-divinylbenzene copolymer are d ', measure the specific surface area of chelating resin after pretreatment, the results are shown in Table 4;

[0128](2) In the catalyst removal unit, the pretreated chelating resin is arranged in the packed tower, and at e'°C, the above-mentioned hydrogenated butadiene-acrylonitrile copolymer solution A prepared at f'g / The flow rate of min passes through the packed tower to remove the precious metal catalyst, wherein the volume ratio of the hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com