Method for cleaning evaporator of clothes dryer, cleaning device and clothes dryer

A cleaning device and evaporator technology, applied in the field of clothes dryers, can solve problems such as rising condensed water temperature, unfavorable heat exchange efficiency, poor cleaning effect, etc., and achieve the effect of improving energy consumption level, good cleaning effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

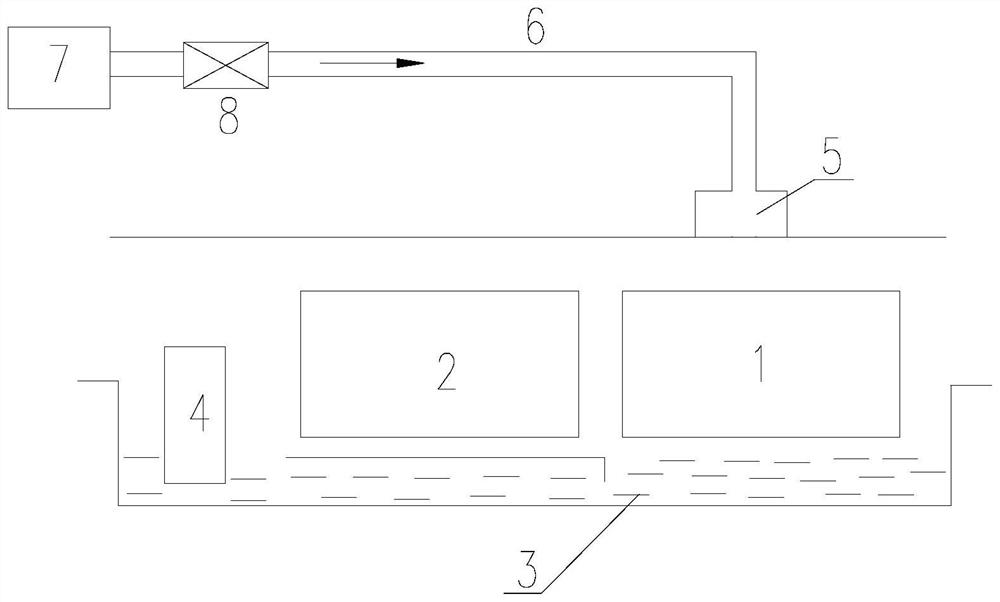

[0027] Such as figure 1 As shown, the clothes dryer evaporator cleaning device provided by the present invention is installed on the heat pump clothes dryer. The heat pump clothes dryer generally includes a shell, and a drum, a compressor, an evaporator 1, a condenser 2, and a drum are installed in the shell. Flow device, fan, controller, etc., wherein, the condenser 2 and the evaporator 1 are installed side by side under the drum, and both the condenser 2 and the evaporator 1 use finned tube heat exchangers, the compressor, the condenser 2, the section The flow device and the evaporator 1 are sequentially connected through refrigerant pipelines to form a refrigerant circulation system.

[0028] There are hot and dry air inlets and hot and humid air outlets on the front and rear of the drum. There is a certain height difference between the hot and dry air inlets and the hot and humid air outlets to ensure that the hot air can be evenly distributed to all parts of the drum, mak...

Embodiment 2

[0042] Such as Figure 4 As shown, the difference from Embodiment 1 is that there is more than one second spray device 9 in the clothes dryer. The second spray device 9 and the pressure spray head can be fixedly installed at the front door of the drum. The spraying device 9 is also connected with the tap water source 7 through a water pipe.

[0043] After multiple drying cycles, the clothes in the drum are completely dry, and the clothes in this state are particularly prone to wrinkles. In this embodiment, the second spraying device 9 is used to spray the inside of the drum, and the sprayed water mist will fall on the clothes, so that the dried clothes in the drum will be in a damp state, thereby realizing the wrinkle removal of the clothes. Moreover, the rotation of the drum can make the water mist evenly spray to all the clothes in the drum, which is used for the spray head.

[0044] In this embodiment, the second spraying device 9 is connected to the tap water source 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com