Water Inlet Control Method of Drum Washing Machine

A drum washing machine and water inlet control technology, which is applied to the control device of washing machines, other washing machines, washing devices, etc., can solve the problems of large differences in water intake of washing machines, large differences in water consumption and power consumption, and washing performance, and achieve improvement. Washing performance, effect of improving energy consumption level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

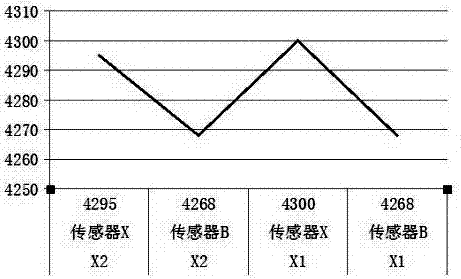

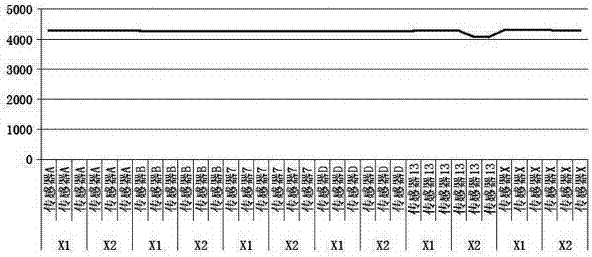

[0029] At present, there are many factors that affect the main washing water consumption of a drum washing machine. The present invention mainly solves the problem that the washing machine liquid level sensor detects the same liquid level frequency due to the difference in the water level sensor manufacturer, the computer board production difference, and the difference in the structure of the washing machine. There is a difference in the actual level of the liquid level, which leads to the difference in the amount of water in the main wash.

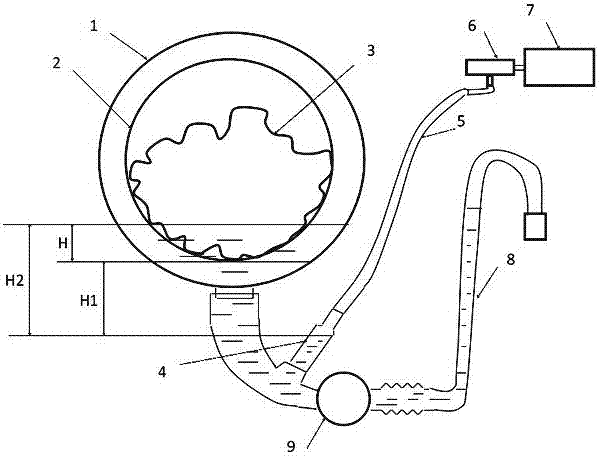

[0030] Such as figure 1 As shown, the structure of the drum washing machine is described. The drum washing machine includes an outer tub 1 and an inner tub 2. In the inner tub 2 is placed the laundry to be washed as a load 3. The water level sensor 6 is connected to the outer tub 1 through the air collecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com