Control method of liquid cooling electric energy system, liquid cooling electric energy system and storage medium

A control method and electric energy technology, applied in electrical components, structural parts of electrical equipment, cooling/ventilation/heating renovation, etc. high power problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

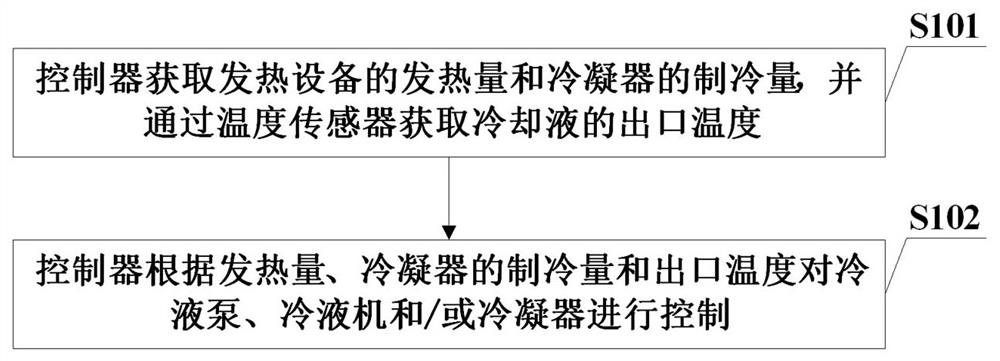

Method used

Image

Examples

Embodiment 2

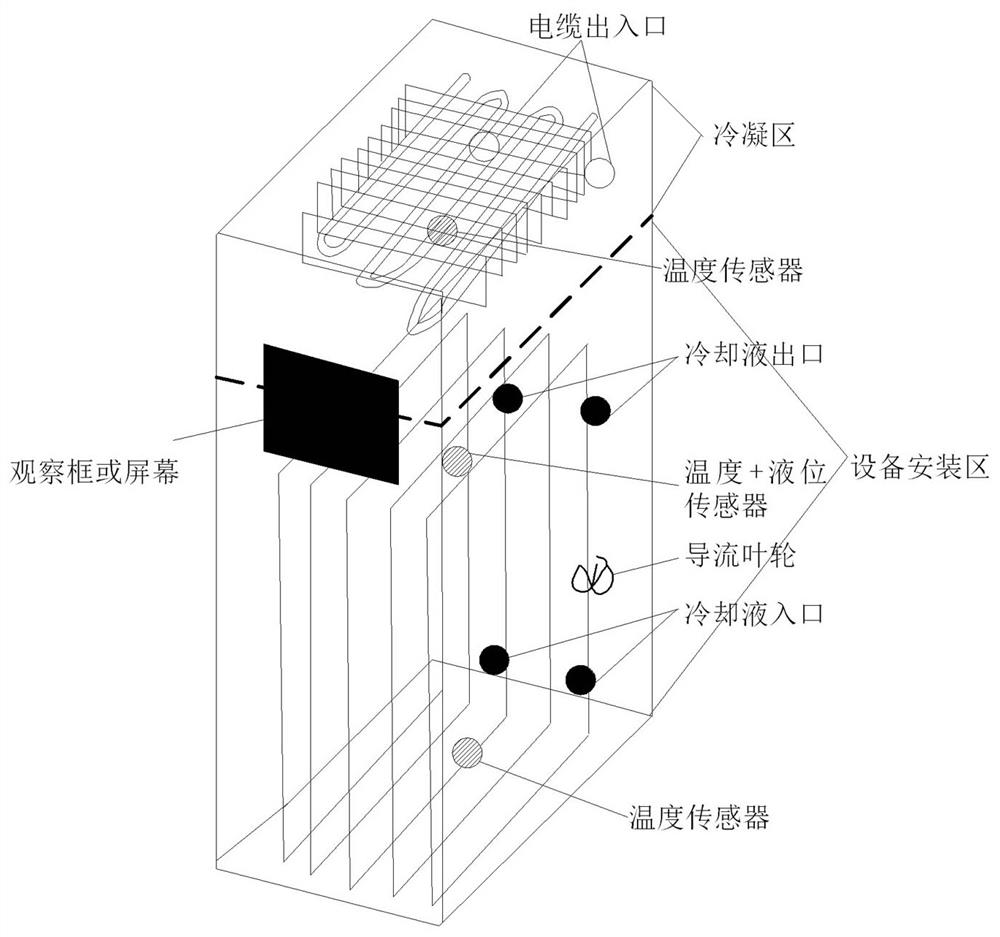

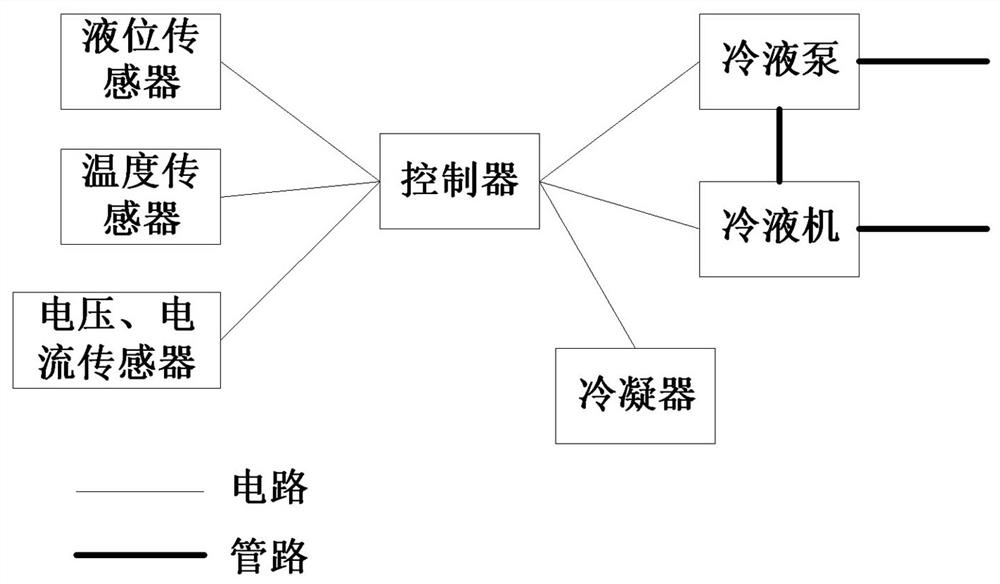

[0061] This embodiment also provides a liquid-cooled power system, such as figure 2 and image 3 As shown, the liquid-cooled power system includes: the equipment installation area and the condensation area located above the equipment installation area. Liquid machine, the cooling liquid pump communicates with the cooling liquid outlet end of the equipment installation area through the pipeline, and the cooling liquid machine communicates with the cooling liquid inlet end of the equipment installation area through the pipeline; the condensation area includes At least one set of condensers; the liquid-cooled power system also includes a controller, the controller is electrically connected to the cooling liquid pump, the cooling machine and the condenser; the controller is used to realize the control method of the liquid-cooled power system described in the above embodiments The steps are not repeated here.

[0062] In this embodiment, the liquid-cooled power system further in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com