Stress-compensation waterproof elastic sealing gaskets for shield tunnel segment joint

A shield tunnel segment and elastic sealing pad technology is applied in tunnels, tunnel linings, wellbore linings, etc., which can solve the problems of insufficient rubber recovery and deformation capacity, stress relaxation, and reduced waterproof capacity of sealing pads, and achieve long-term load holding capacity. Strong, overcoming stress relaxation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

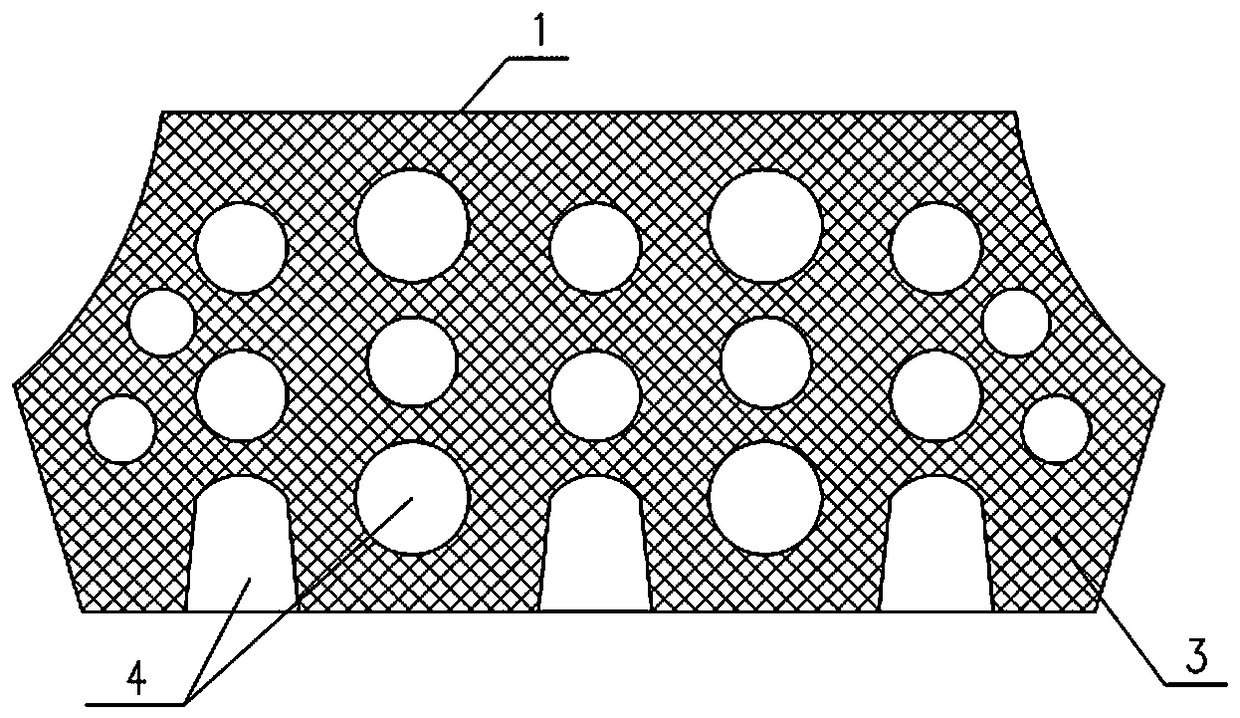

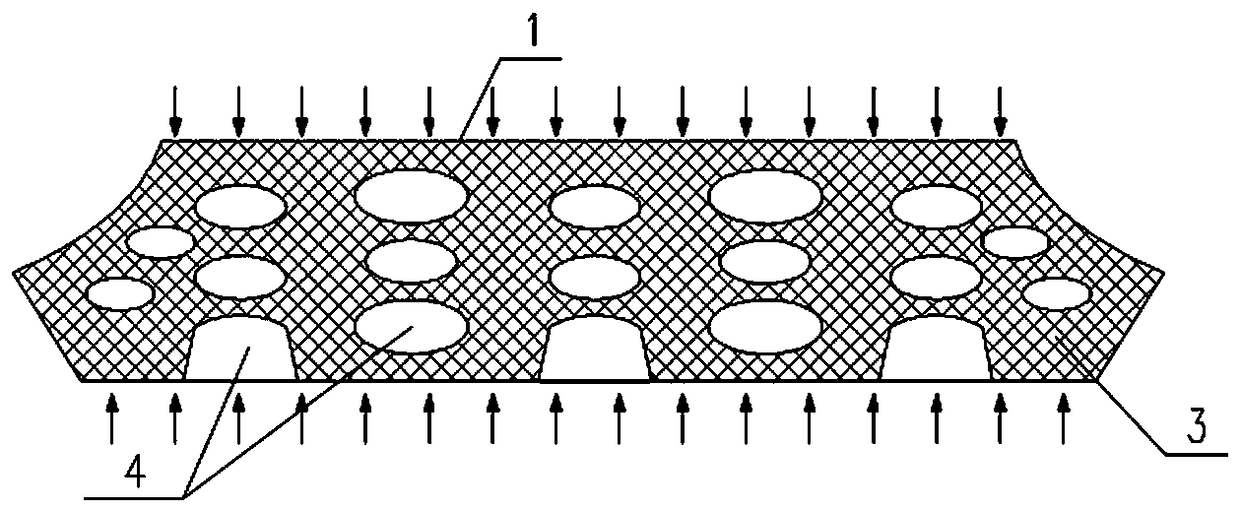

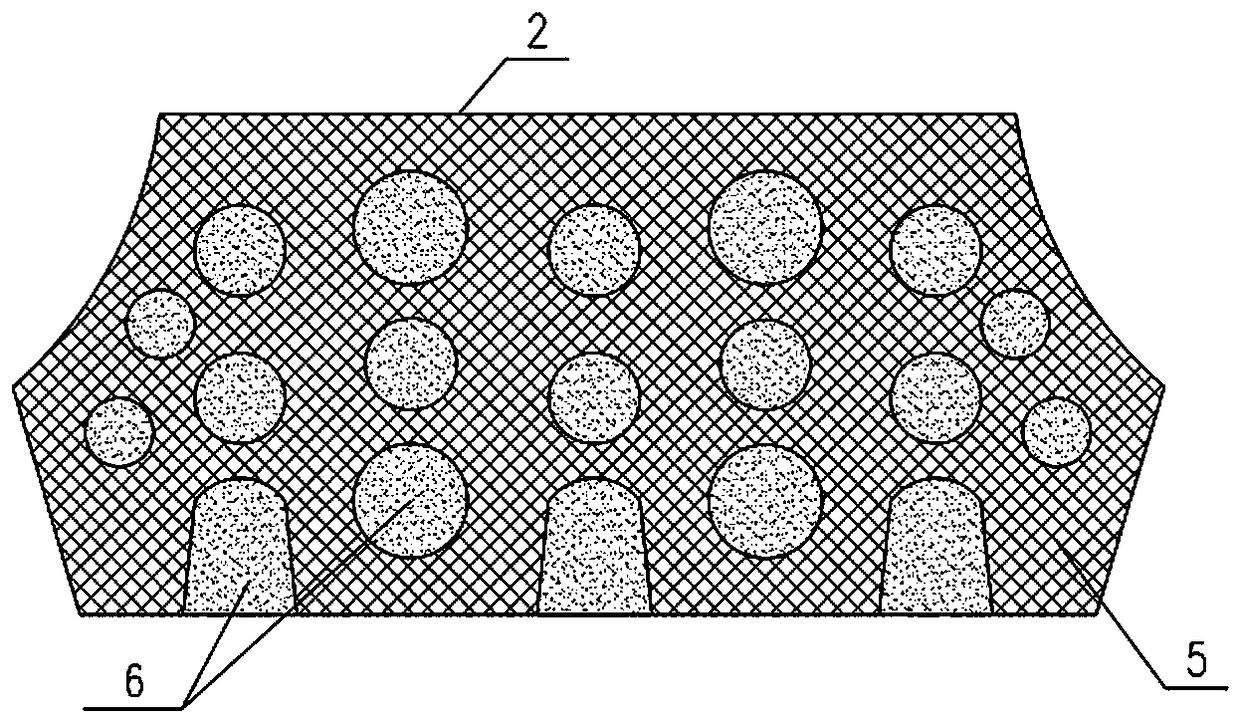

[0029] The figure includes: traditional gasket 1, elastic gasket 2, traditional gasket body 3, traditional gasket through hole 4, EPDM rubber waterproof body 5, CM sponge filling body 6, segment 7, segment waterproof insert Slot 8.

[0030] As shown in the drawings, a shield tunnel segment seam waterproof elastic gasket 2 is composed of EPDM rubber waterproof body 5 and CM sponge filling body 6 .

[0031] Before the shield segment 7 is assembled, the elastic gasket 2 is pasted in the segment waterproof groove 8, and after the segment 7 is spliced, two adjacent elastic gaskets 2 are squeezed against each other, so that the gasket 2 is compressed and deformed. The EPDM waterproof body 5 can generate contact stress after being compressed and deformed, so that two adjacent gaskets 2 and the gasket 2 and the concrete segment 7 can fit each other, thereby...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com