Novel multifunctional wood cutting device

A cutting device and multi-functional technology, applied in the field of new multi-functional wood cutting devices, can solve problems such as danger and weak safety design of cutting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

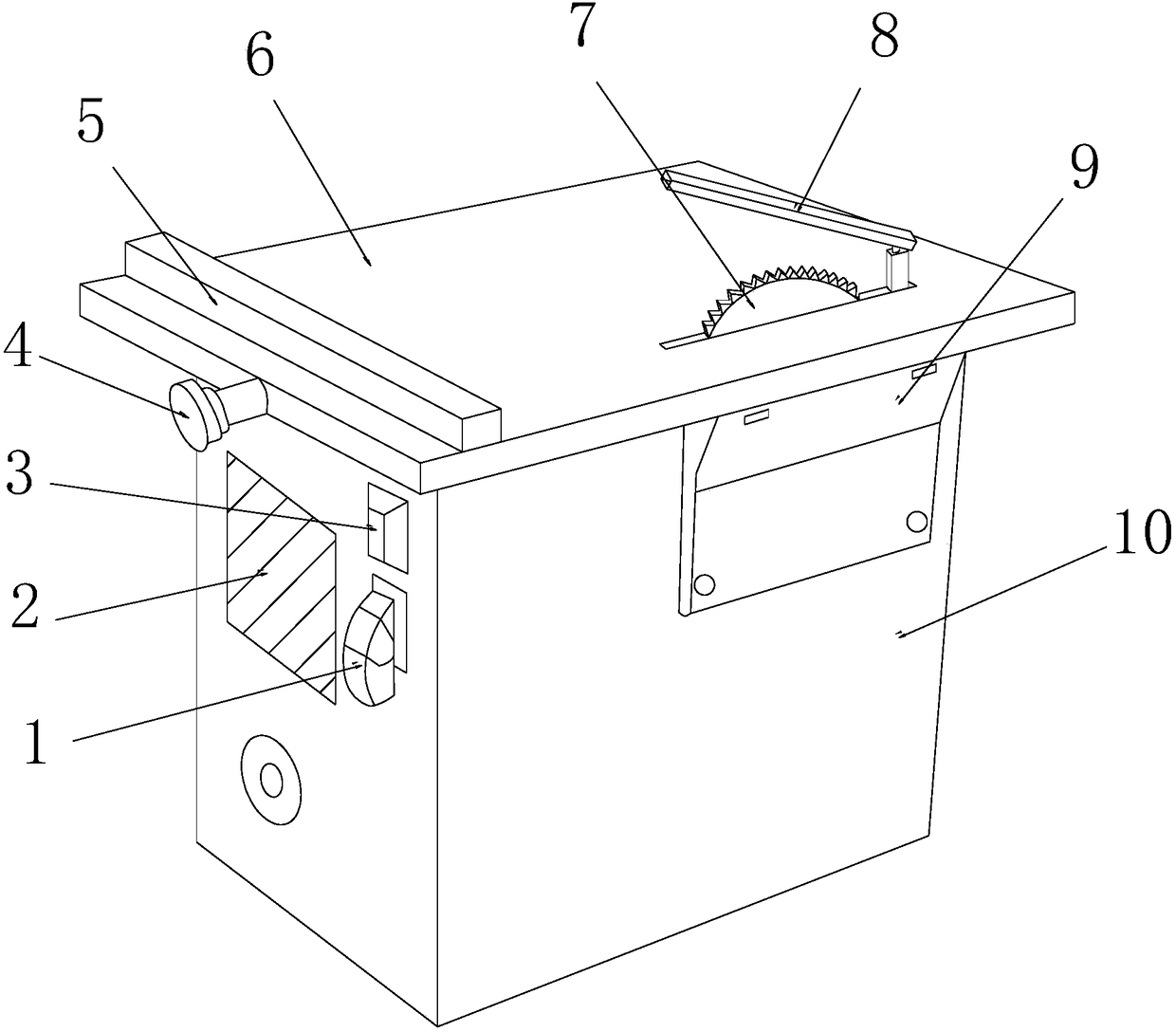

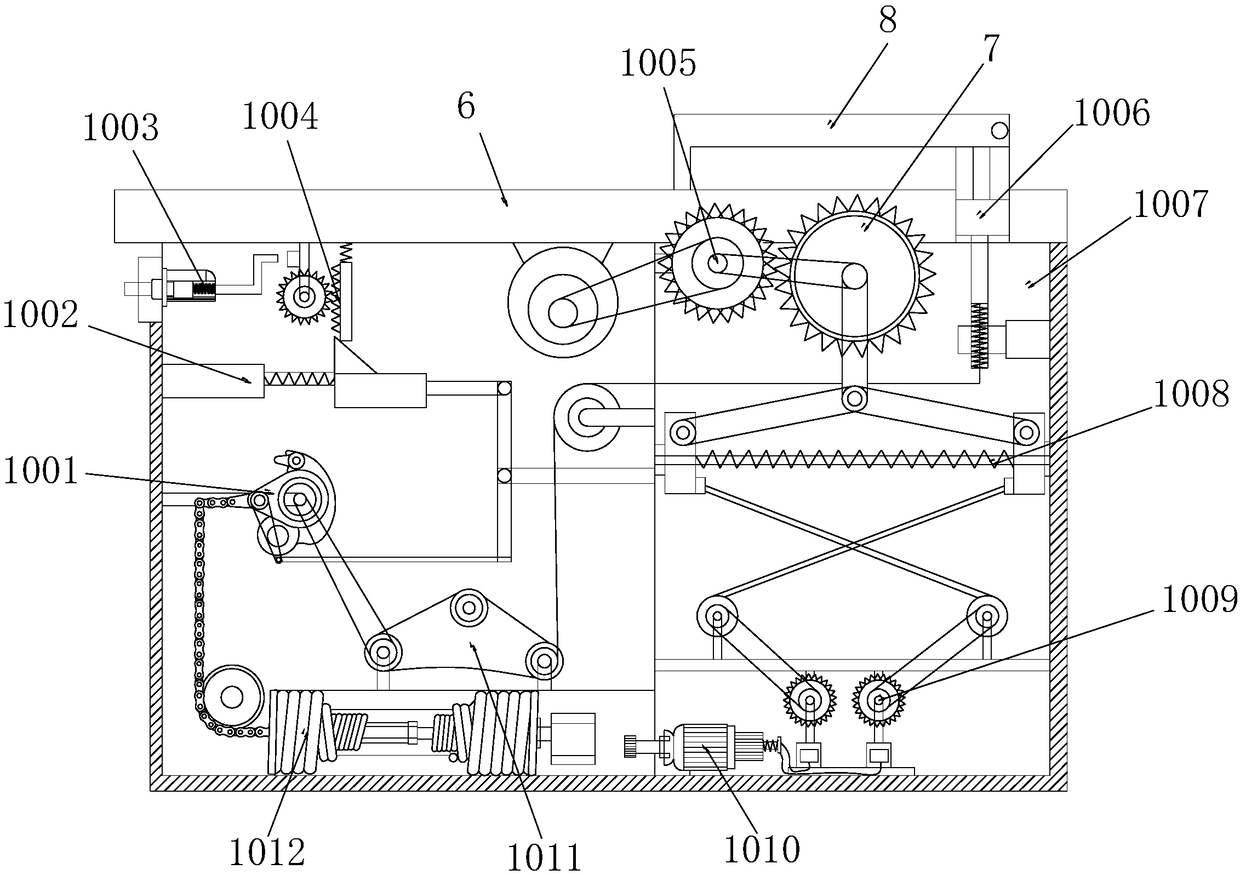

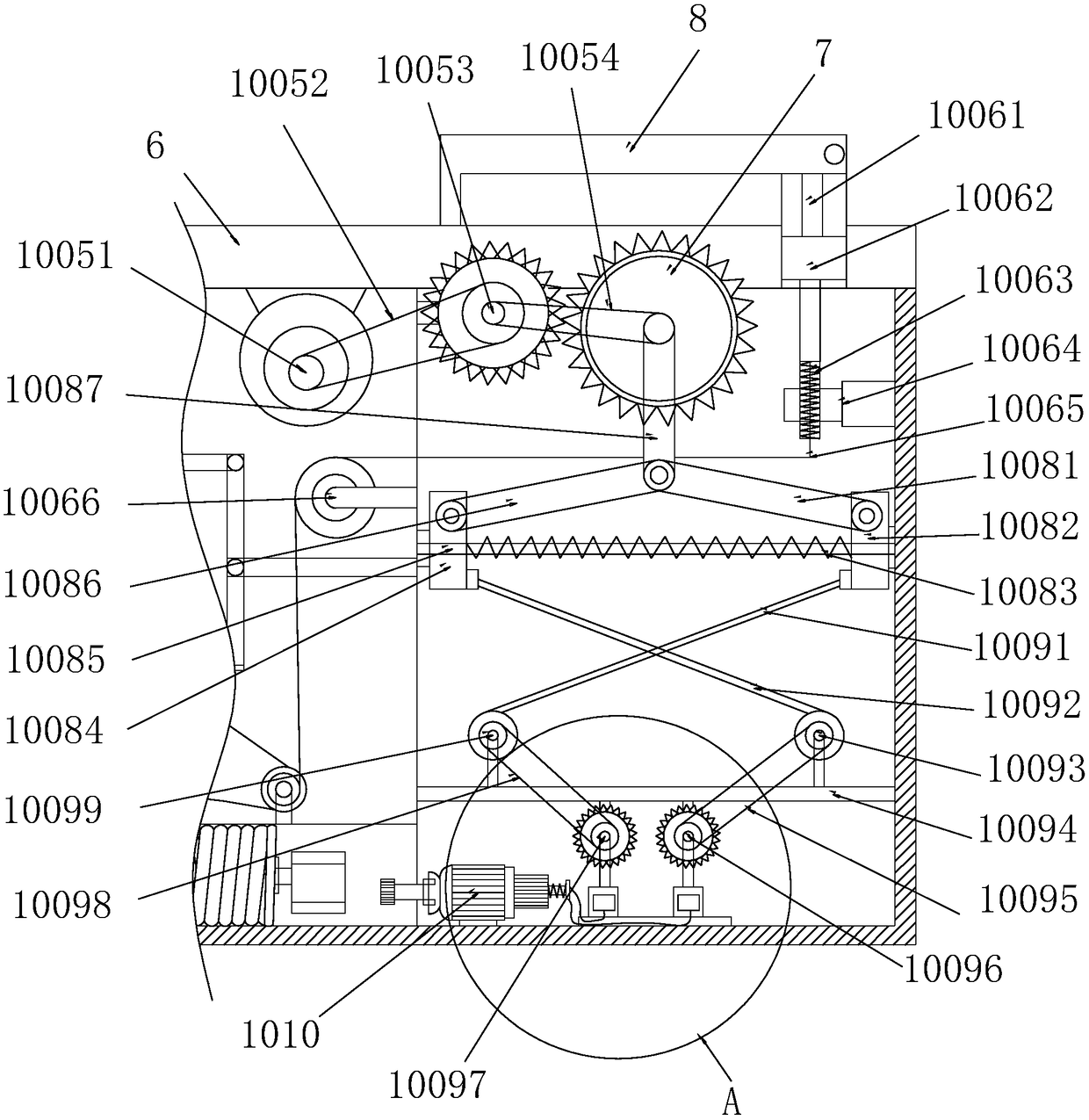

[0030] see Figure 1-Figure 8 , the present invention provides a new type of multifunctional wood cutting device, its structure includes a safety switch 1, a heat dissipation port 2, a control switch 3, a knob 4, a baffle plate 5, a working surface 6, a saw blade 7, a safety shield 8, an inspection Door 9, control main box 10, the upper end of the control main box 10 is welded with a worktable 6 and is an integrated structure, the upper end of the worktable 6 is mechanically connected with a baffle 5 and the inside is hinged with the knob 4, the knob 4 penetrates and is installed on the left end edge of the working table 6, and the working table 6 is located at the right end of the baffle plate 5, and is chiseled with an opening for clearance fit with the saw blade 7, and the bottom end of the saw blade 7 is mechanically connected to the control main box 10 Inside, the safety shield 8 cooperates with the saw blade 7 and its bottom end is fixed on the inside of the control main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com