Non-return valve with high impact resistance and wear resistance

A wear-resistant and impact-resistant technology, applied in functional valve types, control valves, valve devices, etc., can solve the problems of impact resistance, poor wear resistance, inability to adapt to high-pressure pipelines, etc., to achieve impact resistance and High wear resistance, preventing fluid backflow and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

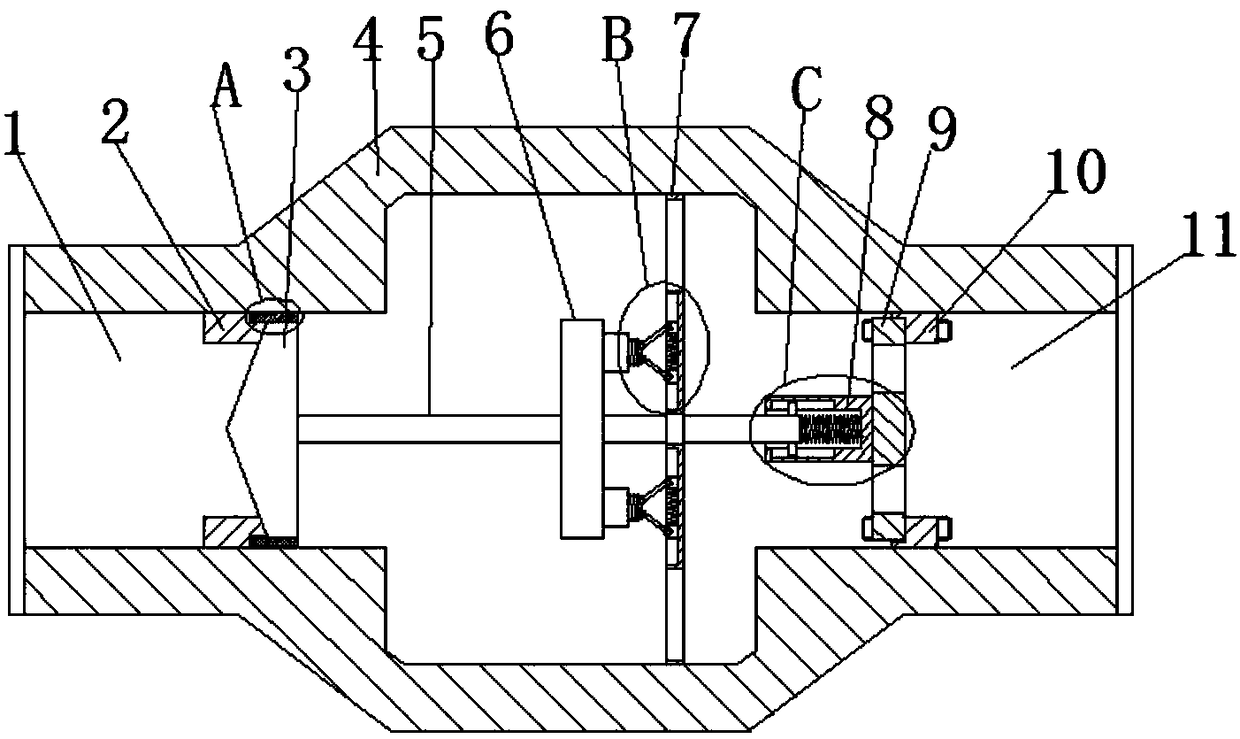

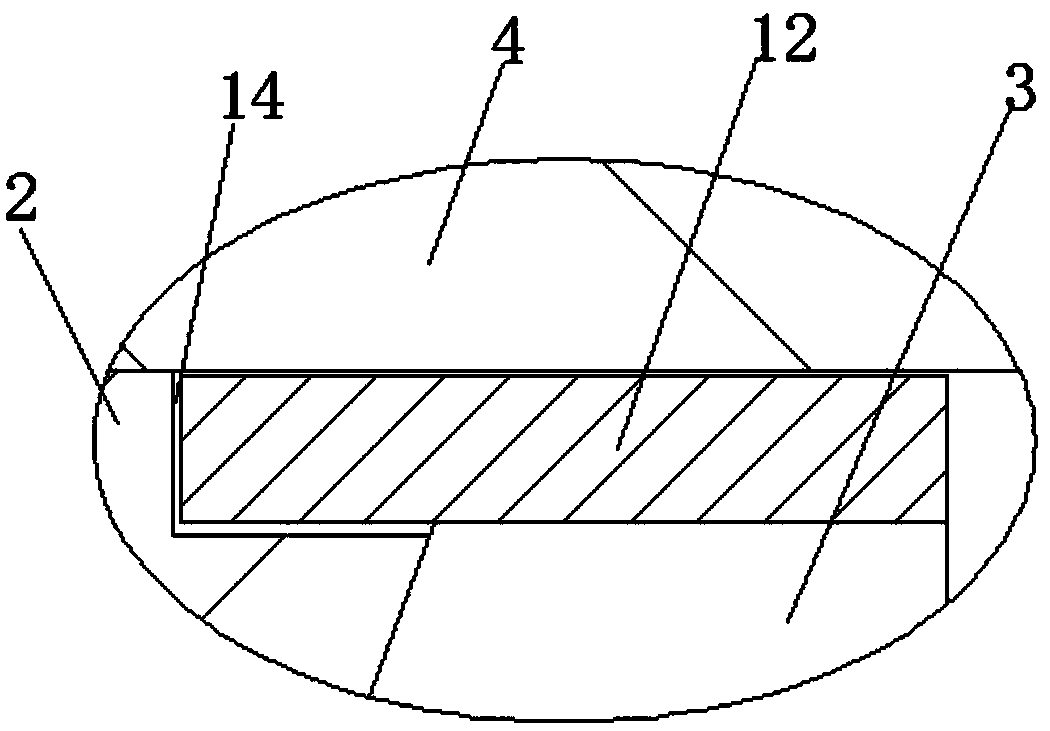

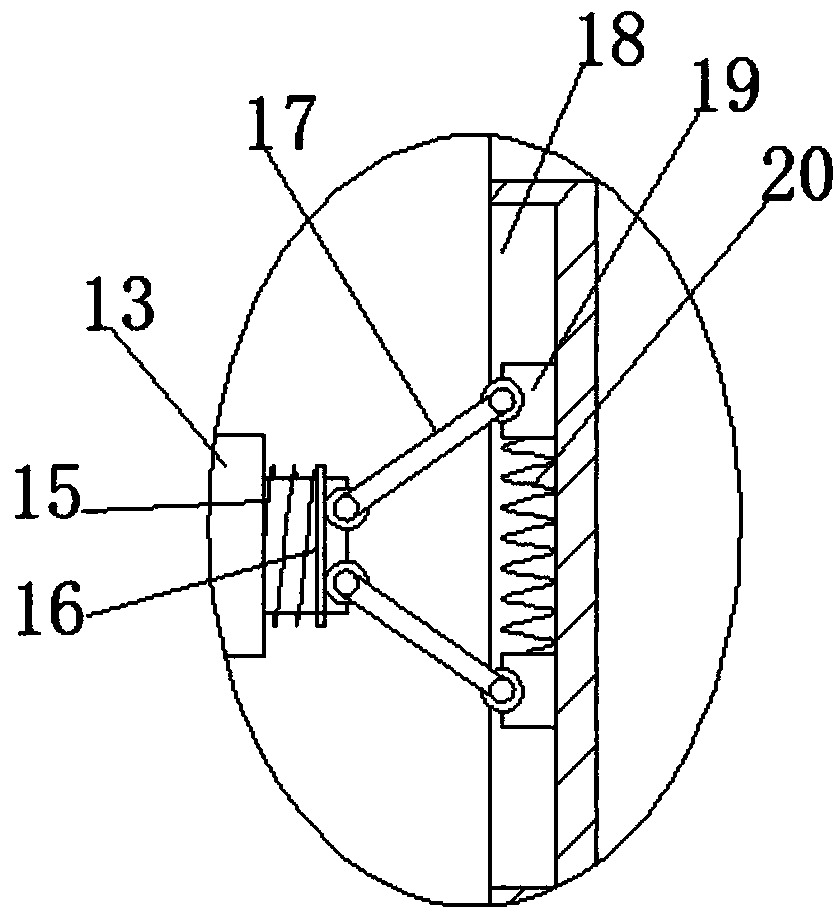

[0017] Reference Figure 1-4 , A check valve with high impact resistance and wear resistance, including a valve body 4, the valve body 4 is a hollow structure, and a side wall of the valve body 4 is provided with a water inlet 1, and the inner wall of the water inlet 1 is provided with The first retaining ring 2, one side wall of the first retaining ring 2 is provided with a tapered groove, and the side of the baffle 3 away from the moving rod 5 is provided with a tapered surface matching the inclined surface. On the one hand, the impact can be reduced, and the other On the one hand, the friction on the baffle 3 can be reduced, and the wear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com