Novel wide-necked two-way valve with mechanical sealing function

A mechanical seal, two-way valve technology, applied in mechanical equipment, valve details, multi-way valves, etc., can solve problems such as adverse effects of equipment use, material blockage in conveying pipelines, poor sealing performance, etc., to avoid adverse effects, The effect of good sealing and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

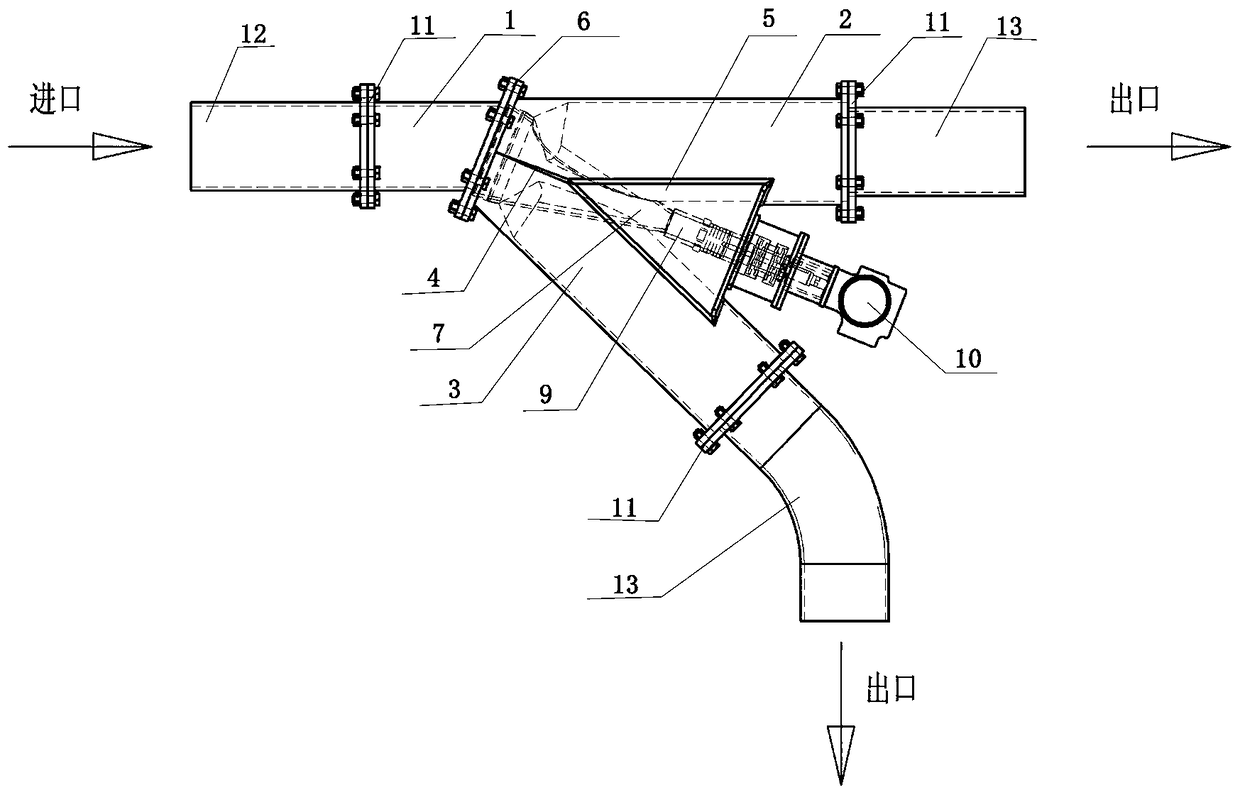

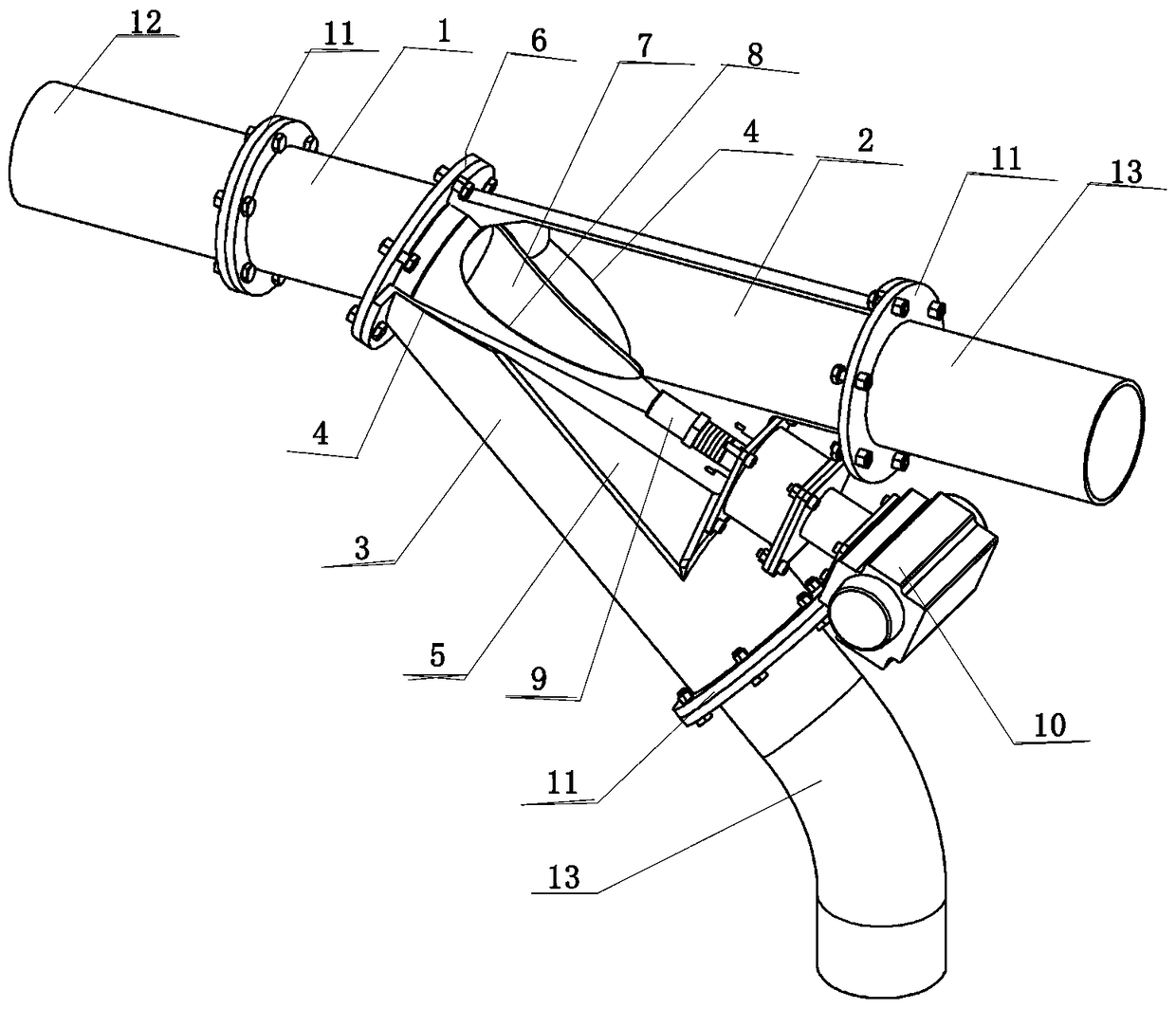

[0015] Example: see figure 1 and figure 2 , in the figure, 1-feed pipe, 2-first discharge pipe, 3-second discharge pipe, 4-inclined notch, 5-triangular fixing bracket, 6-flange, 7-conical valve plug, 8 -Oval hole, 9-screw rod, 10-motor, 11-connecting flange, 12-inlet pipe, 13-outlet pipe.

[0016] A new wide-mouth double-way valve with a mechanical seal, including a feed pipe 1 and a discharge pipe, the discharge pipe includes a first discharge pipe 2 and a second discharge pipe 3, the first discharge pipe 2 and the second discharge pipe One end of the material pipe 3 is cross-connected through the inclined notch 4, and forms an inclined circular connection port. The junction of the first discharge pipe 2 and the second discharge pipe 3 is provided with a triangular fixed bracket 5, and the circular connection port It is connected with the feed pipe 1 through the flange 6, and a conical valve plug 7 is arranged in the circular connection port. The plug 7 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com