Three-axis holder

A technology of gimbal and axis, applied in the field of three-axis gimbal, can solve the problems of gimbal volume, excessive weight, improper stacking, etc., and achieve the effect of being beneficial to control, reducing volume and weight, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

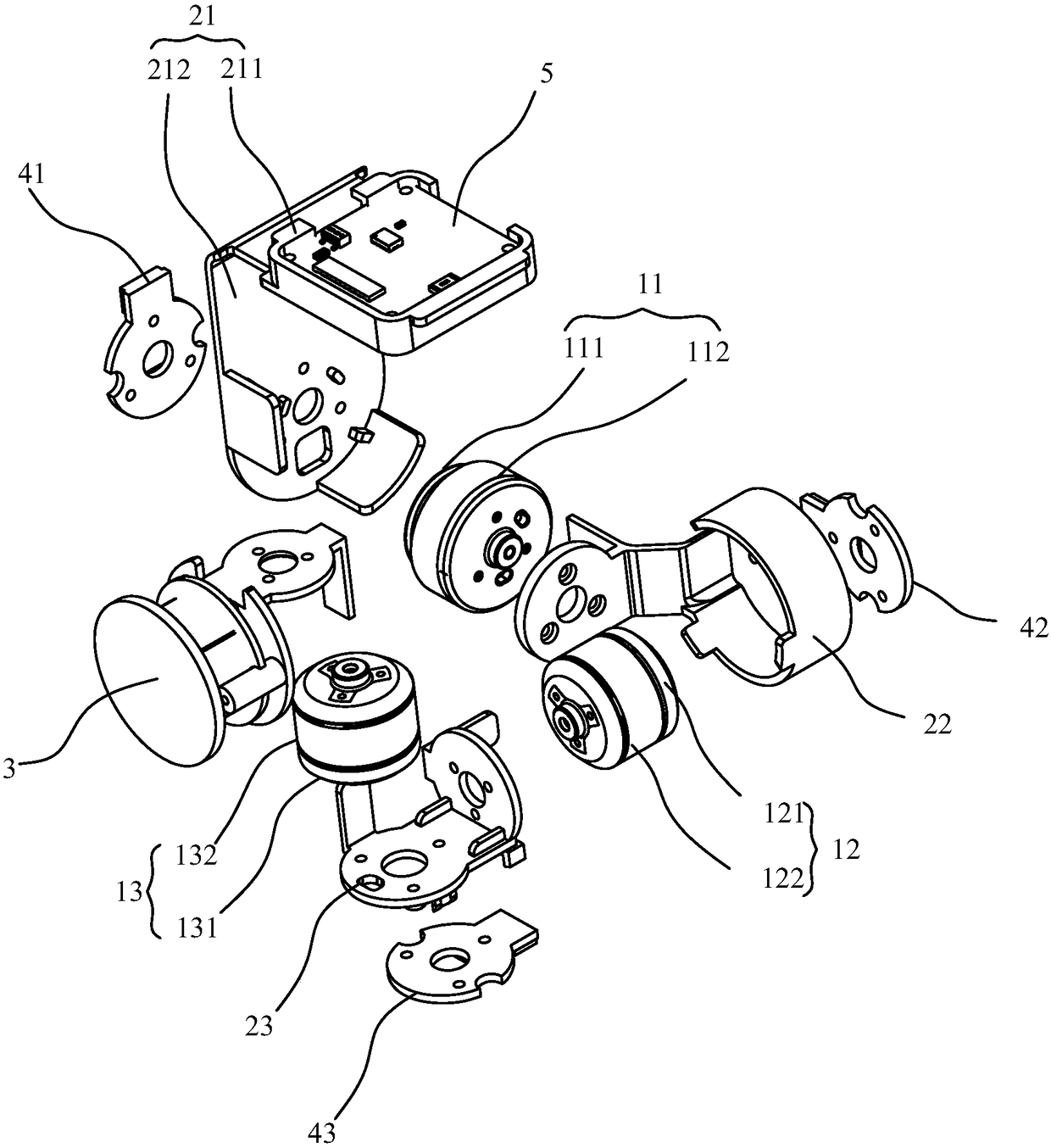

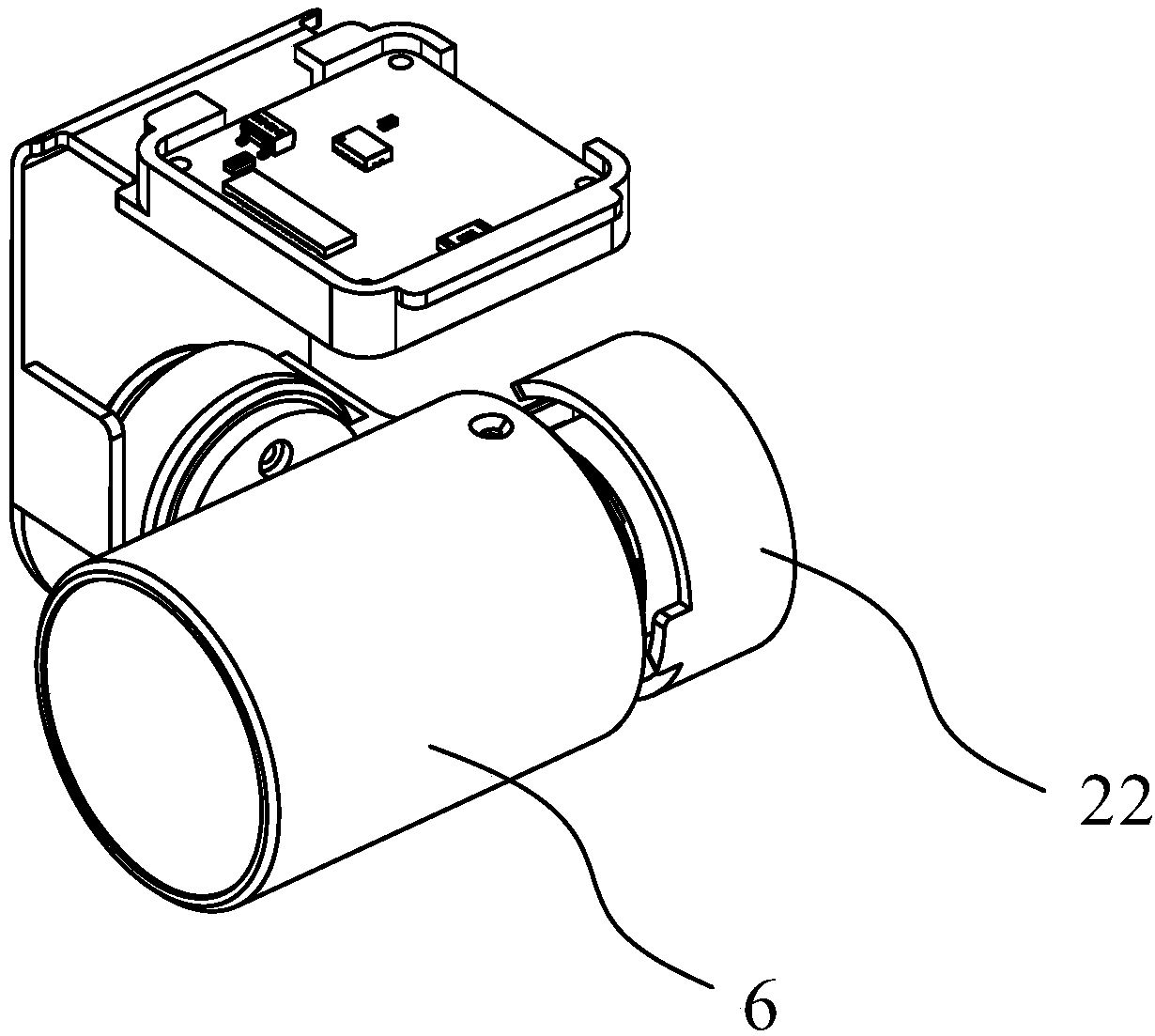

[0068] Such as Figure 1-Figure 6 As shown, the present embodiment discloses a three-axis gimbal, including a carrier 3, a first fixing frame 21, a second fixing frame 22, a third fixing frame 23, a first motor 11, a second motor 12 and a third motor 13.

[0069] Such as figure 1 As shown, the first motor 11 is connected with the first fixed frame 21 and the second fixed frame 22 respectively, and is used to make the second fixed frame 22 rotate relative to the first fixed frame 21; the second motor 12 is respectively connected with the second fixed frame 22 It is connected with the third fixed frame 23 and is used to make the third fixed frame 23 rotate relative to the second fixed frame 22 . The third motor 13 is connected to the third fixing frame 23 and the carrier 3 respectively, and is used to make the carrier 3 rotate relative to the third fixing frame 23 .

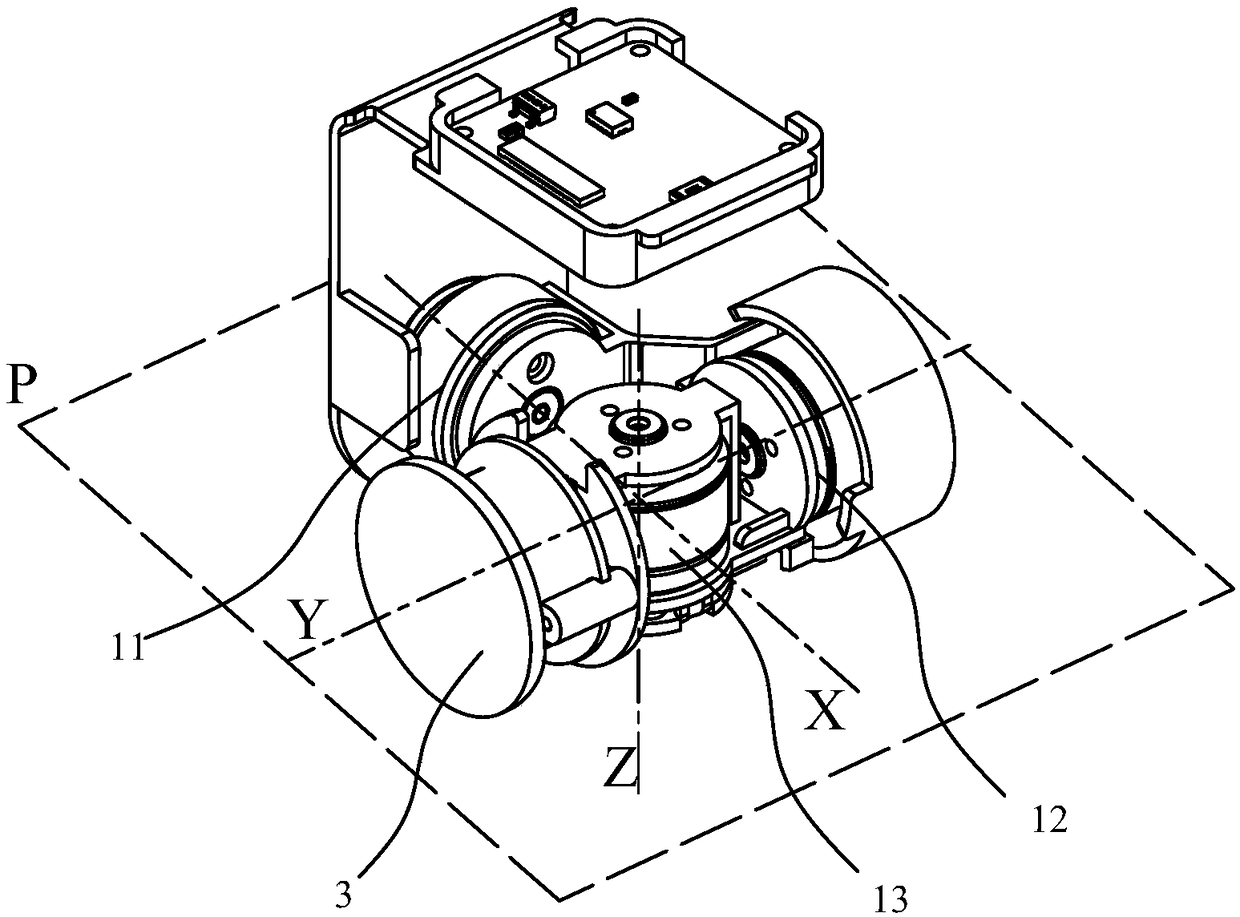

[0070] Thus, if image 3 As shown, the rotation around the axis X of the first motor 11 can be realized by t...

Embodiment 2

[0087] Such as Figure 7-Figure 10 As shown, the difference between this embodiment and Embodiment 1 lies in the change of the first motor 11 and the third motor, which leads to the change of the arrangement of the motors.

[0088] Such as Figure 7 As shown, in this embodiment, the rotation around the axis Z of the first motor 11 can be realized by the first motor 11, the rotation around the axis Y of the second motor 12 can be realized by the second motor 12, and the rotation around the axis Y of the second motor 12 can be realized by the third motor. 13 can realize the rotation around the axis X of the third motor 13 . (In Embodiment 1, the axis of the first motor 11 is the axis X, and the axis of the third motor 13 is the axis Z, that is, the axes of the first motor 11 and the third motor 13 are interchanged.)

[0089] Such as Figure 7 As shown, the axis Z of the first motor 11 , the axis Y of the second motor 12 and the axis X of the third motor 13 are perpendicular t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap