Automatic pineapple picking method

A fully automatic, pineapple technology, applied in agricultural machinery and implements, applications, harvesters, etc., can solve problems such as high labor costs, failure to effectively judge maturity, hot picking environment, etc., and achieve the effect of simple control scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

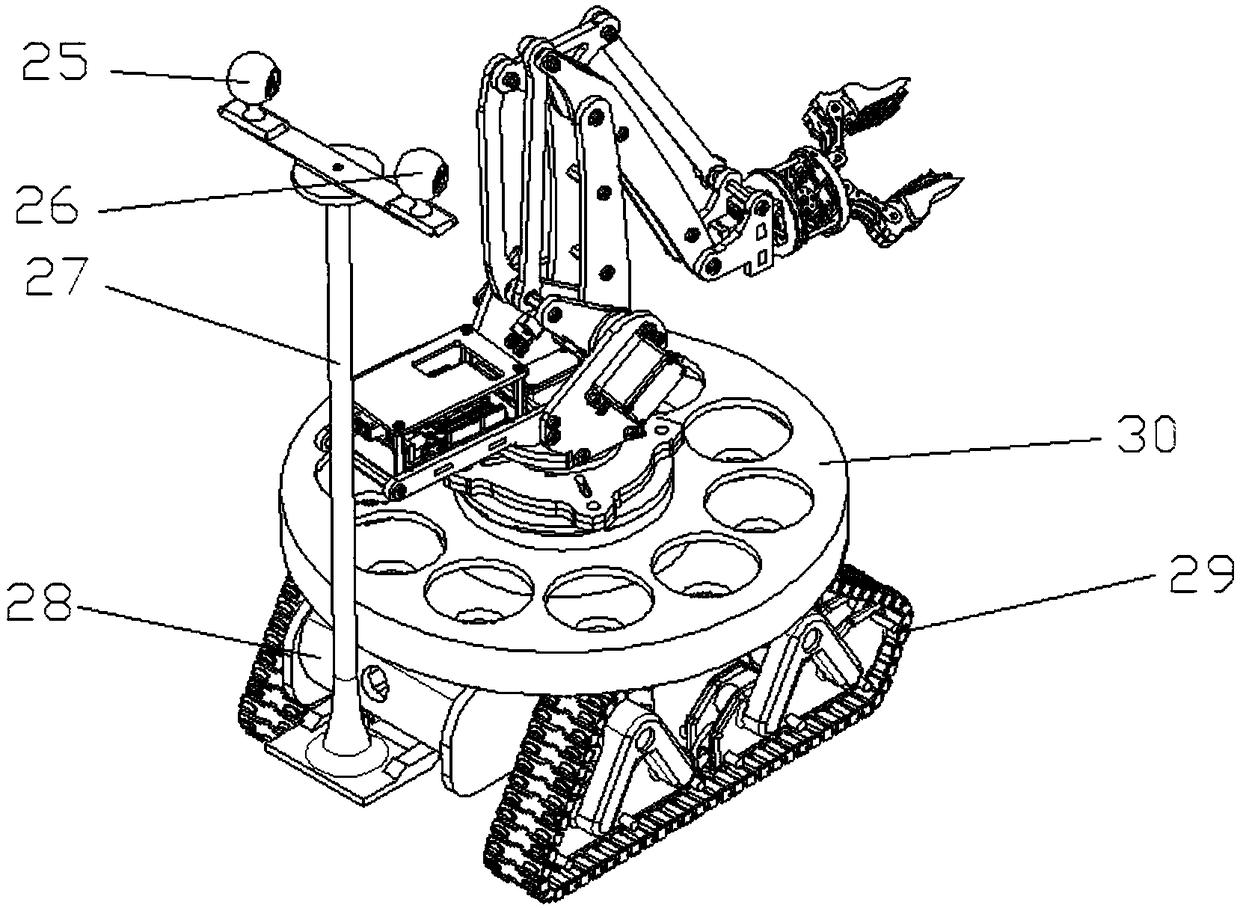

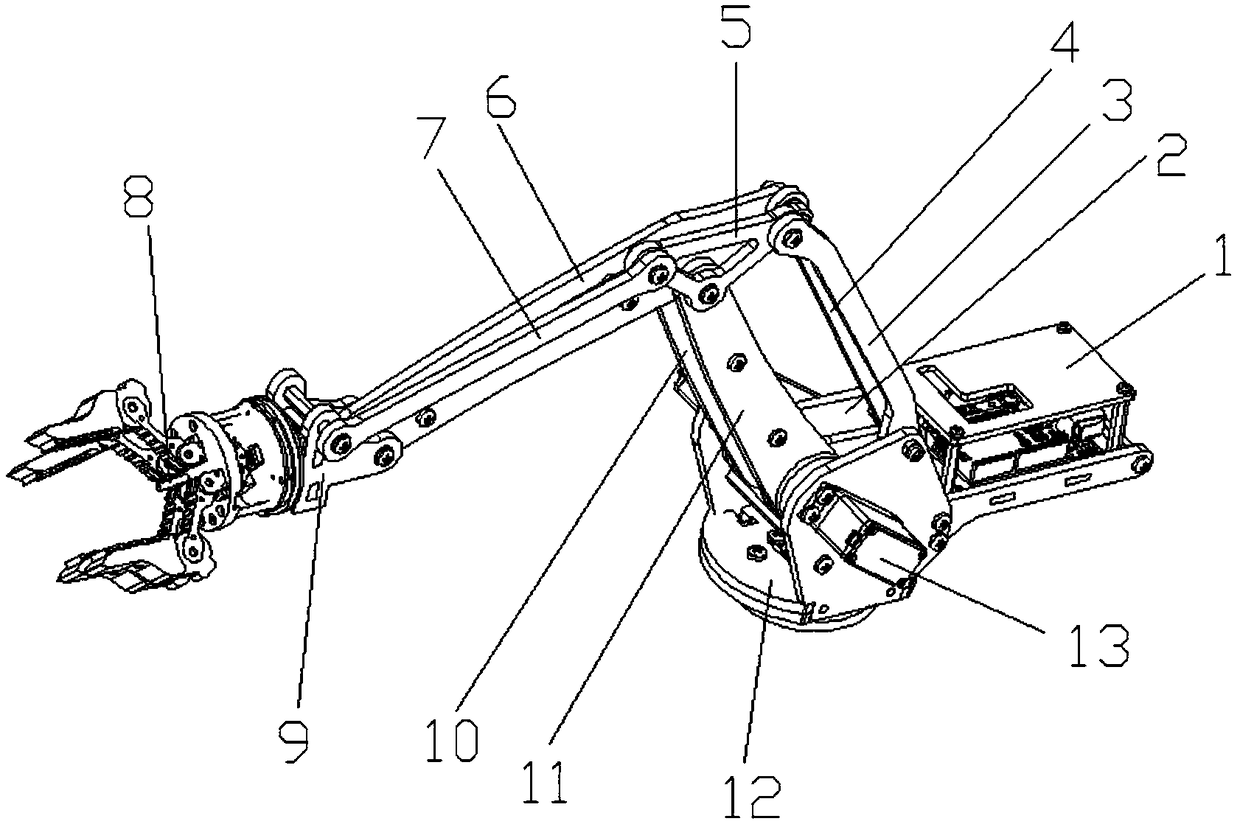

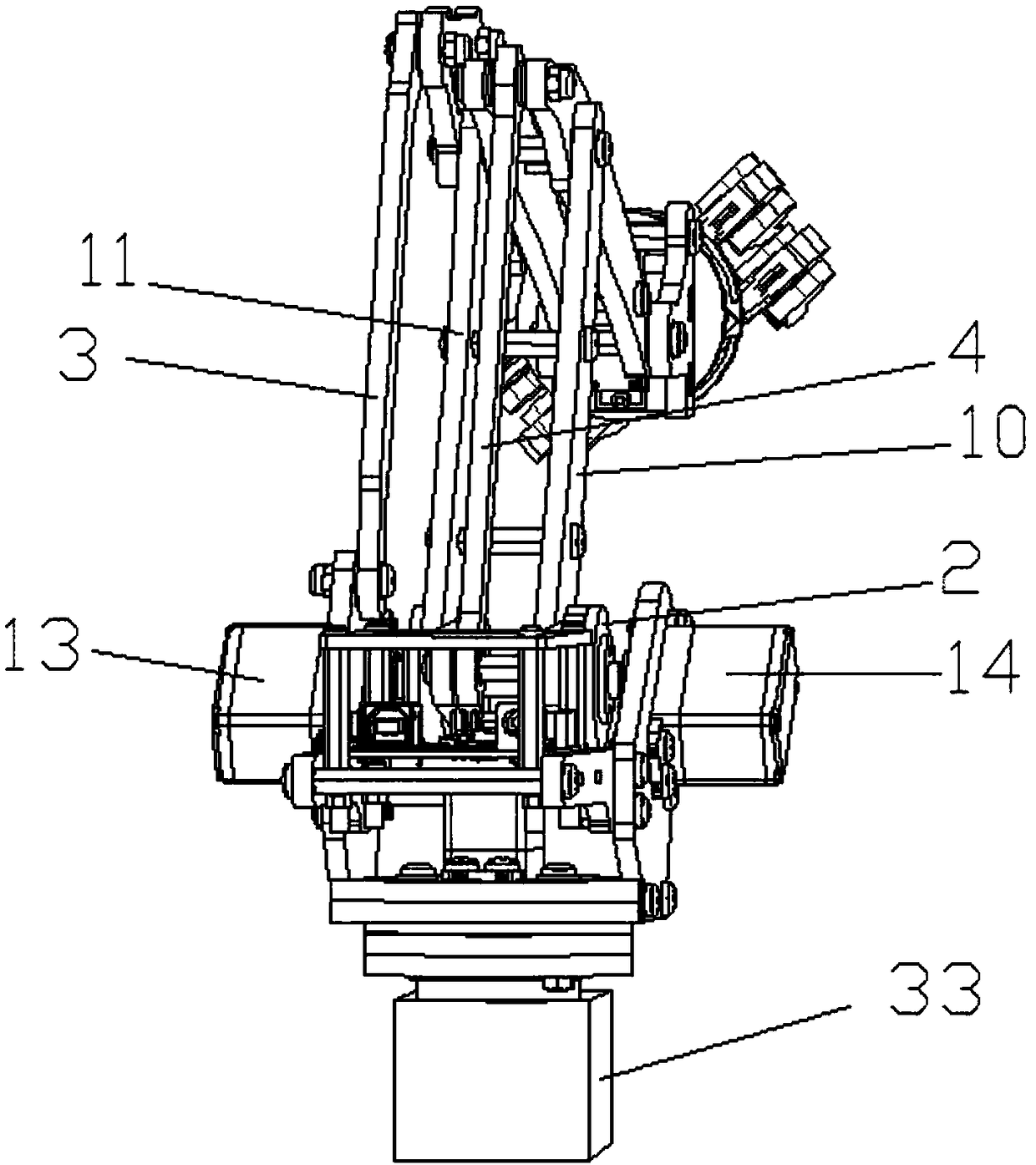

[0030] like Figure 1-15 As shown, there is a kind of full-automatic pineapple picking method, comprising car body (28), described car body (28) is provided with rotating disk (30), and described rotating disk is provided with some vacancies (36), and described vacancy is provided with There is a pressure sensor (32), the turntable (30) is provided with a picking actuator, the picking actuator is provided with a control system (1), and the front end of the car body (28) is provided with a camera bracket (27), A visual collection system is arranged above the camera bracket, and the visual collection system includes a first camera (25) and a second camera (26).

[0031] Further, the front end of the picking actuator is provided with a clamping finger system, and the clamping finger system includes a clamping finger support frame (9), and a clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com