Desilting structure and hydraulic engineering desilting device

A technology for water conservancy projects and dredging devices, which is applied in the directions of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. It can solve the damage of suction pumps, scrapped water conservancy facilities, and easily blocked pipelines, etc. problem, to achieve the effect of strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

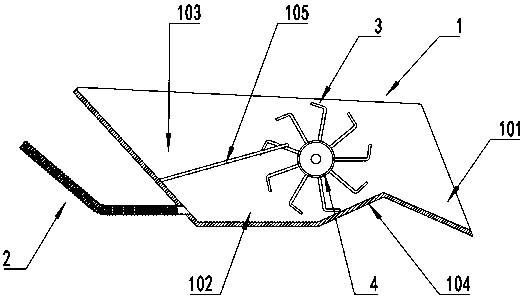

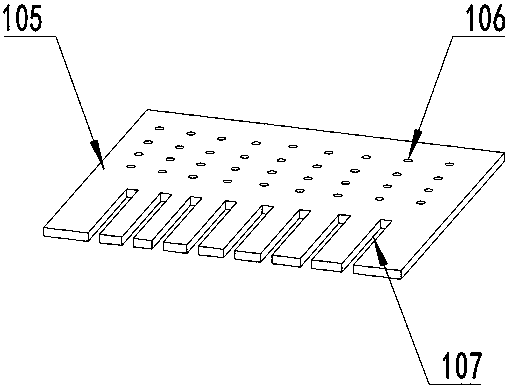

[0021] see Figures 1 to 2 , In the embodiment of the present invention, a dredging structure includes a bucket body 1 and a feeding claw 3. The bucket body 1 includes a feeding part 101, a connecting part 104 and a mud storage part 102 connected in sequence. The bottom of the feeding part 101 is inclined and the bottom of the mud storage part 102 is set horizontally. It enters into the mud storage part 102 through the connecting part 104 for storage, and the feeding claws 3 are fixed on the drum 4 . A plurality of the feeding claws 3 are distributed along the radial and circumferential directions of the drum There is a gap between the two feeding claws 3. The feeding claws 3 are of L-shaped structure, which is convenient for picking up stones and large-volume impurities in the sludge, and at the same time, it will not affect the normal movement of the sludge. The outer edge is opposite to the feeding part 101. Due to the angle setting of the feeding part 101, the sludge will...

Embodiment 2

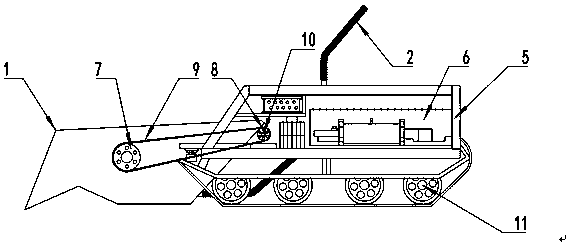

[0026] see image 3 , In the embodiment of the present invention, on the basis of the above embodiment, a dredging device for water conservancy projects is also proposed, which includes a device body, and also includes a dredging structure installed at the front end of the device body as described in the above embodiment.

[0027] Specifically, the device body includes a vehicle body 5 and a crawler wheel 11 installed on the vehicle body 5 . The crawler wheel 11 is used as a traveling device, which has wide adaptability. Of course, the vehicle body 5 is provided with a drive for driving the crawler wheel 11 . Mechanism, a drive motor 10 is installed on the vehicle body 5, and a driving pulley 8 is installed at the output end of the driving motor 10. The driving pulley 8 is connected with the driven pulley 7 at the shaft end of the drum 4 through the synchronous belt 9 to realize the drum. 4 and the rotation of the feeding claw 3, at the same time, a suction pump 6 connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com