Numerical control electric screw press screw spike molding tool

A technology of spiral spikes and forming tooling, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problem of insufficient sealing height, short material return distance, and inability to produce long-sized products To achieve the effect of increasing accuracy and timeliness, facilitating clamping and retrieving materials, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

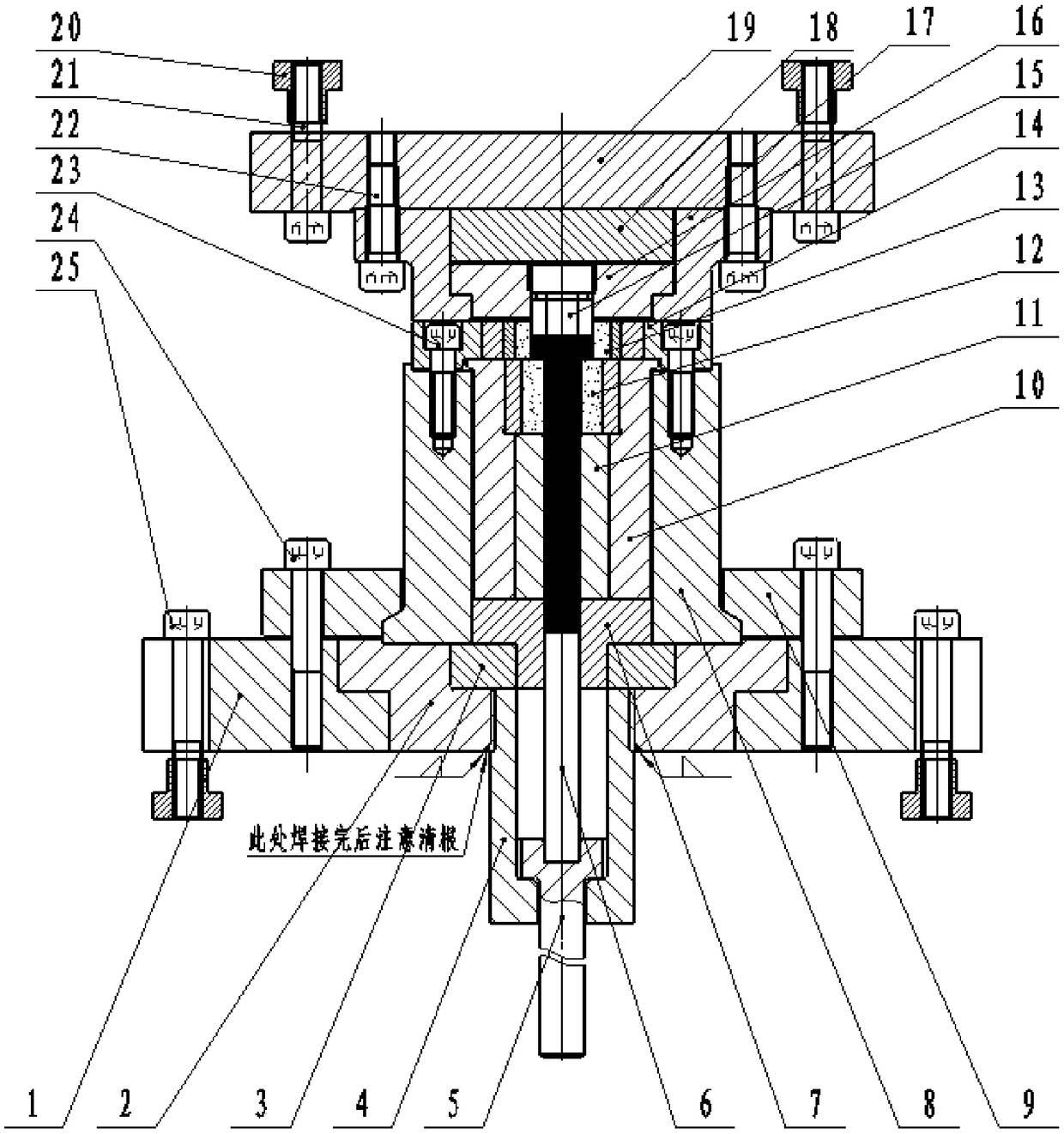

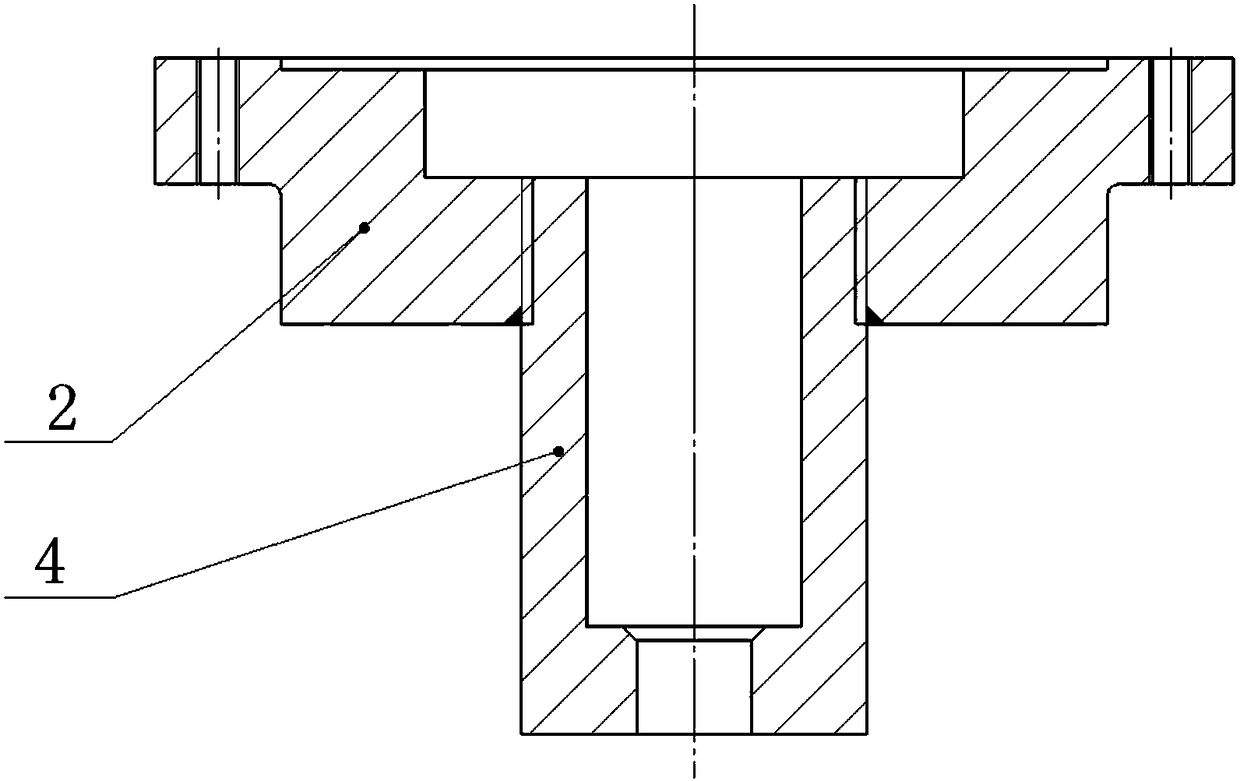

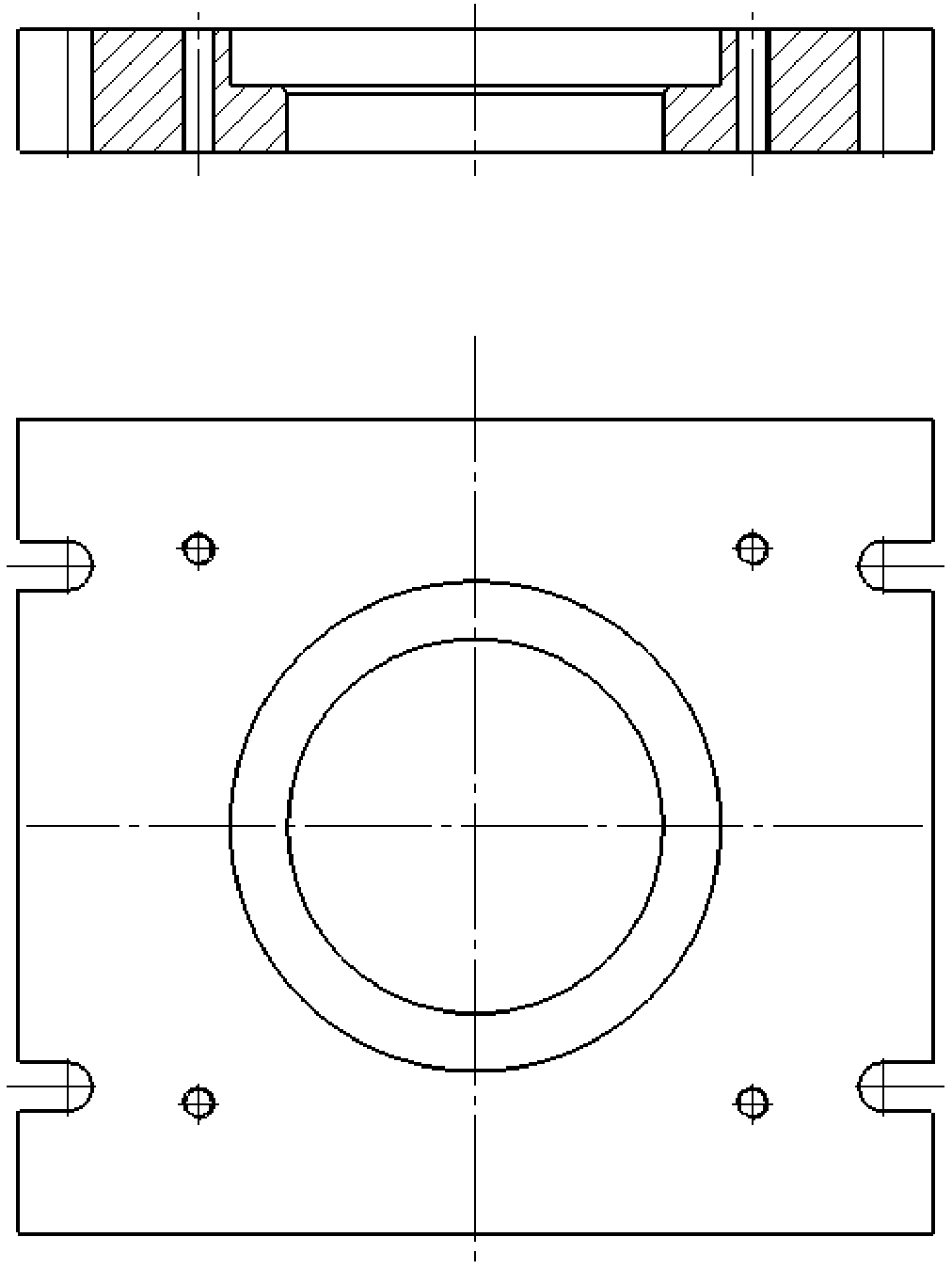

[0024] A numerical control electric screw press spiral spike forming tooling, such as Figure 1 to Figure 16 As shown, it includes: lower die backing plate 1, lower step pad 2, support pad 3, lower jacking punch sleeve 4, lower jacking punch 5, tail punch 6, adjustment pad 7, lower die sleeve 8, lower die fixing plate 9. Lower mold shell 10, guide mold 11, lower round mold 12, hexagonal mold 13, hexagonal mold jacket 14, hexagonal upper punch 15, upper punch fixing sleeve 16, upper mold cover 17, upper mold pad 18, upper mold backing plate 19. T-shaped iron 20, M20x100 hexagon socket head screw 21, M20x70 hexagon socket head screw 22, M16x50 hexagon socket head screw 23, M24x100 hexagon socket head screw 24, M20x120 hexagon socket head screw 25, etc., among which:

[0025] The lower mold backing plate 1 is installed on the workbench of the CNC electric screw press through the T-shaped iron 20 and the M20x120 hexagon socket head screw 25. The lower step pad 2 and the lower jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com