Discharging control method adopting manual interfaces for shot blasting machine

A control method and shot blasting machine technology, applied in abrasives, manufacturing tools, abrasive jet machine tools, etc., to achieve the effect of improving production efficiency and production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

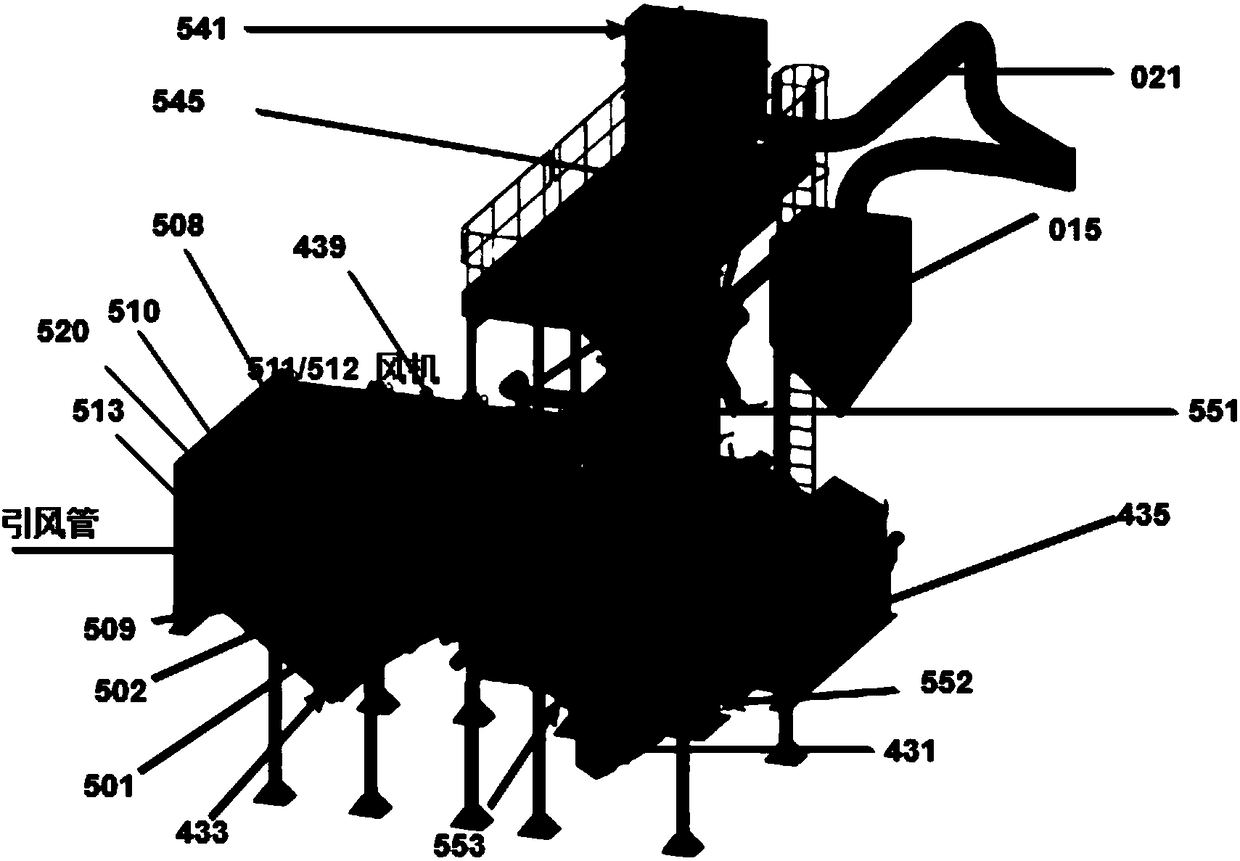

[0019] The invention is mainly applicable to the rapid treatment of the problem of material blocking when the shot blasting machine is started. Schematic diagram of shot blasting machine figure 1 shown, where:

[0020] 015 and 021 represent cartridge dust collectors;

[0021] 431 represents the screw conveyor in the shot blasting area;

[0022] 433 represents the screw conveyor in the cleaning area;

[0023] 435 represents the screw conveyor in the entrance area;

[0024] 439 represents the vertical screw conveyor in the cleaning area;

[0025] 501 represents the scraper screw conveyor;

[0026] 502 means scraper;

[0027] 508 represents the screw conveyor before the main rotating brush;

[0028] 509 represents the bristles of the table below;

[0029] 520 means the bristles on the upper table;

[0030] 510 represents the main rotating brush;

[0031] 511, 512 represent fans;

[0032] 513 represents a spiral brush;

[0033] 541 means bucket elevator;

[0034] 545 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com