spreader

A spreader and lifting lug technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of high cost of spreader, difficulty of lifting, increase of risk of lifting, deformation of tower flange, etc., so as to reduce the difficulty of lifting, The effect of low manufacturing cost and reduced lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Now, embodiments according to the present invention will be described in detail with reference to the accompanying drawings, examples of which are shown in the accompanying drawings, in which the same reference numerals always denote the same components.

[0039] Hereinafter, the spreader according to the embodiment of the present invention will be used as the main spreader of the tower as an example for description, but the spreader according to the embodiment of the present invention is not limited to this, and it can also be applied to other hoisting devices according to actual conditions. Pieces.

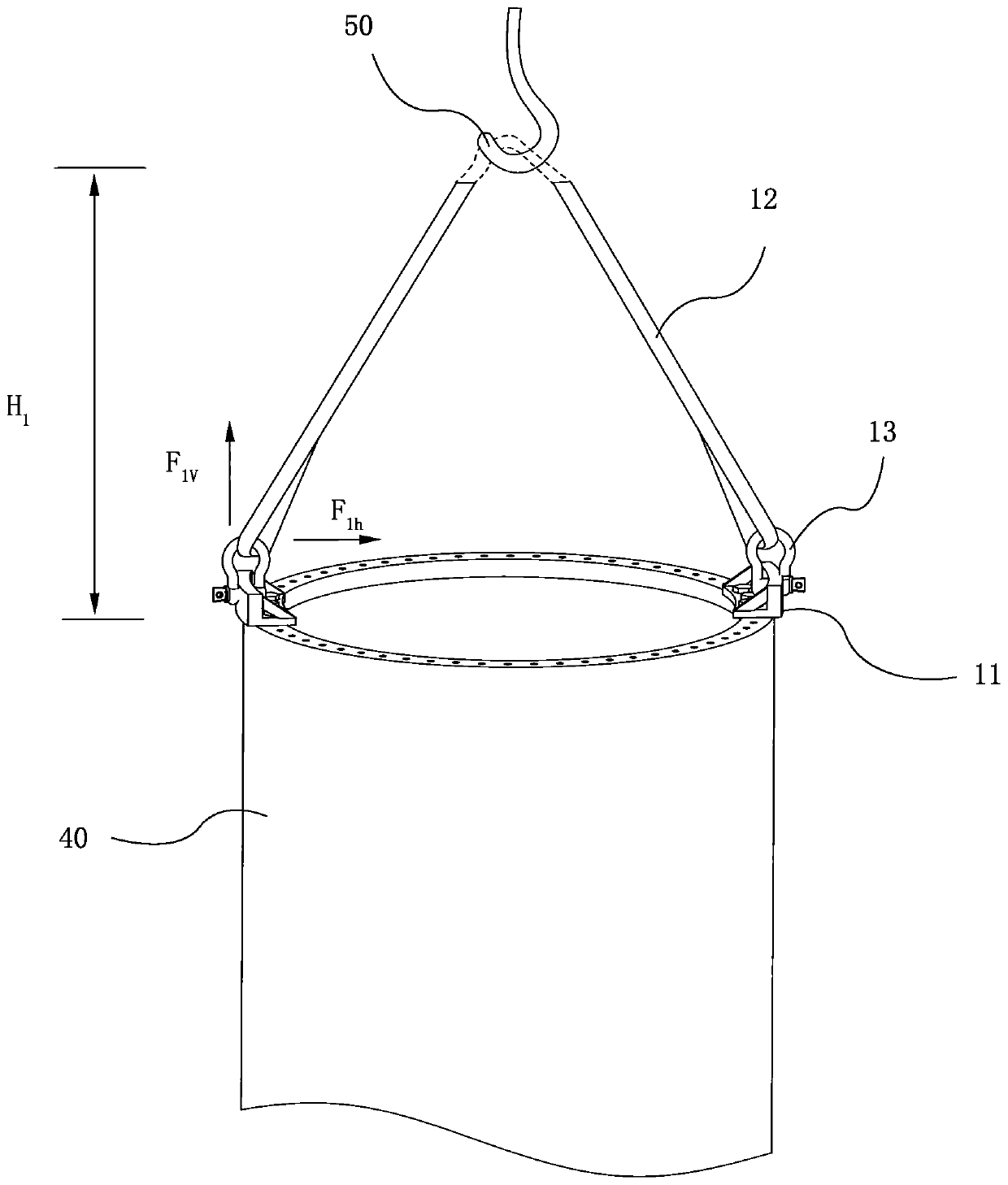

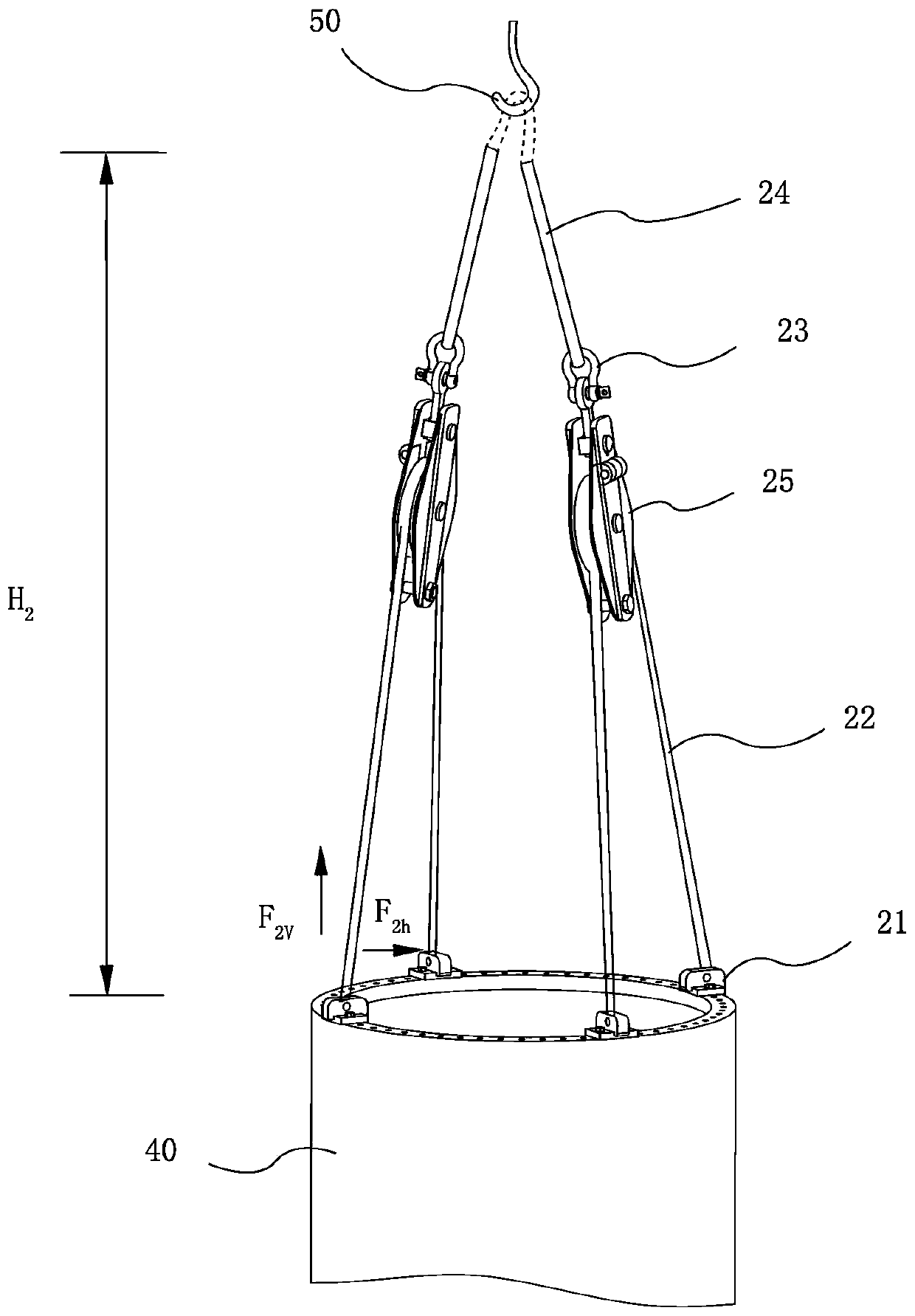

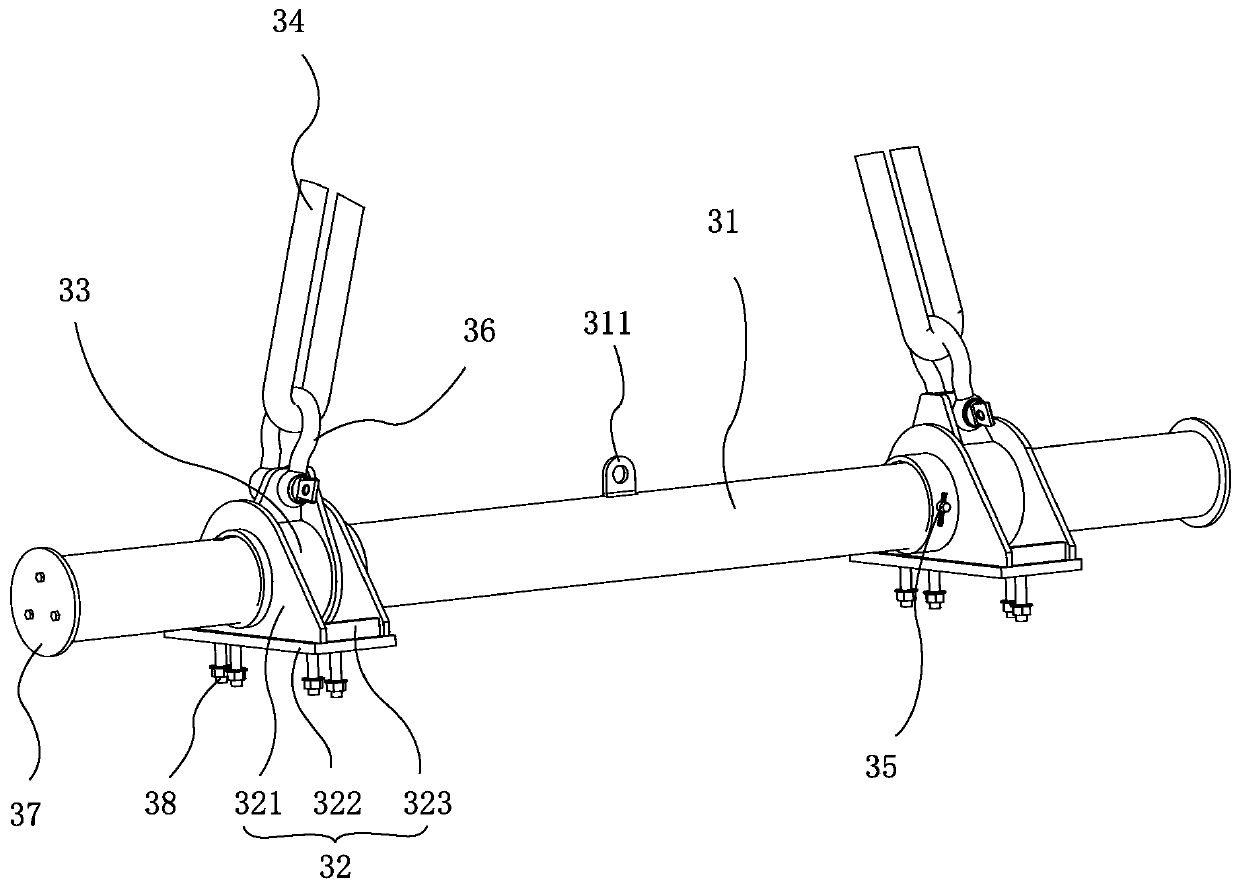

[0040] Such as image 3 with Figure 4 As shown, the spreader may include a lifting beam 31, lifting lugs 32, and a lifting strap 34. The cross section of the hanging beam 31 is approximately circular, preferably circular, and can be solid or hollow. Two lifting lugs 32 are detachably installed on the hanging beam 31 to connect such as the tower 40 (see Picture 10 ) Waiting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com