An adaptive prestressed anchor composite soil nail wall and its construction method

A composite soil nailing and prestressing technology, which is used in excavation, sheet pile wall, foundation structure engineering, etc. High chemical degree, simple and feasible construction method, and the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples. The given examples are only used to explain the present invention and are not limited to this example. After reading the present invention, all equivalent replacements and modifications made within the principle of the present invention belong to the protection scope of the present invention.

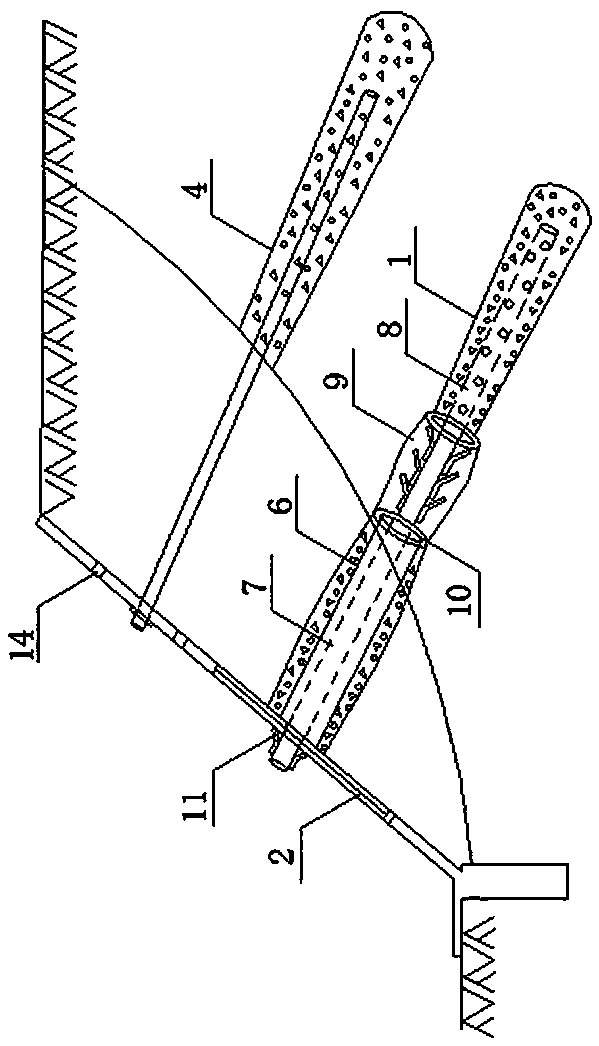

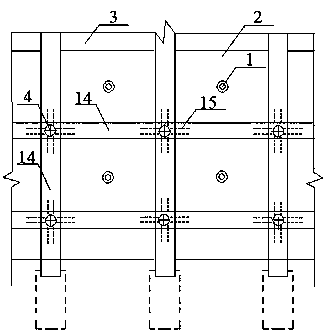

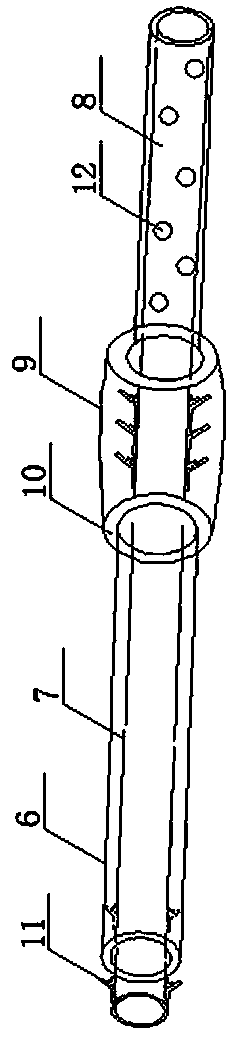

[0018] The working principle of the present invention: (1) Deformation coordination principle: when the tension prestress is applied to the anchor rod, the surrounding soil will retract, and at the same time, the self-shrinking soil nail can shrink in one direction and become shorter with the retraction of the soil , The soil retaining plate can also be dynamically attached to the soil with the retraction of the self-shrinking soil nail, so the anchor rod will not weaken the anchoring force of the soil nail after the tensile prestress is applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com