Coal mine downhole measurement method

An underground measurement and coal mine technology, applied in the field of measurement engineering, can solve the problems of low measurement accuracy, heavy task of underground re-measurement wire, affecting underground production, etc., to improve work efficiency, reduce the time for site erection, and eliminate overall errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

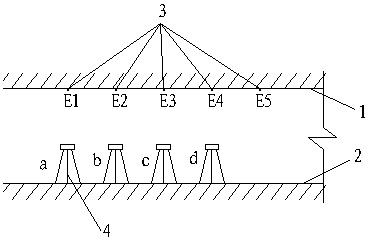

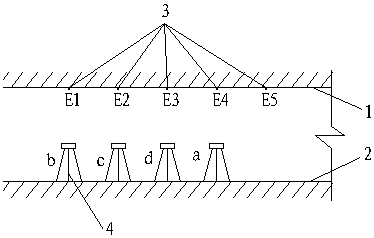

[0012] according to figure 1 , figure 2 As shown, when measuring in the underground roadway, the measurement station 3 is arranged on the roadway roof 1 (E1-E5 in the figure), and the corresponding measurement station 3 is placed on the roadway floor 2 respectively (a-d in the figure). Step 1 When the measurement is first started, based on the conventional three (a, b, c) measurements, set up in advance such as figure 1 The fourth measuring frame (d) is shown as a preliminary measuring station.

[0013] Step 2 After step (1) is completed, as long as the first station measurement is completed, the second station measurement can be carried out immediately, without waiting for the centering and leveling of the front sight, and at the same time, the figure 1 The first frame in (a) moves forward and becomes in position figure 2 The fourth measuring frame (a) in ; follow step 2 in turn until the end of this measurement task.

[0014] All simple modifications, changes and equiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com