Management method for tool delivery and storage

A management method and tool technology, applied in the field of management of power safety tools in and out of the warehouse, can solve problems such as data inconsistency, missing inspection, and inability to update the inventory status of tools and tools, and achieve simple judgment methods, improved accuracy, and easy management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above and other objects, features and advantages of the present invention more apparent, the following specifically cites the embodiments of the present invention, together with the accompanying drawings, for a detailed description as follows.

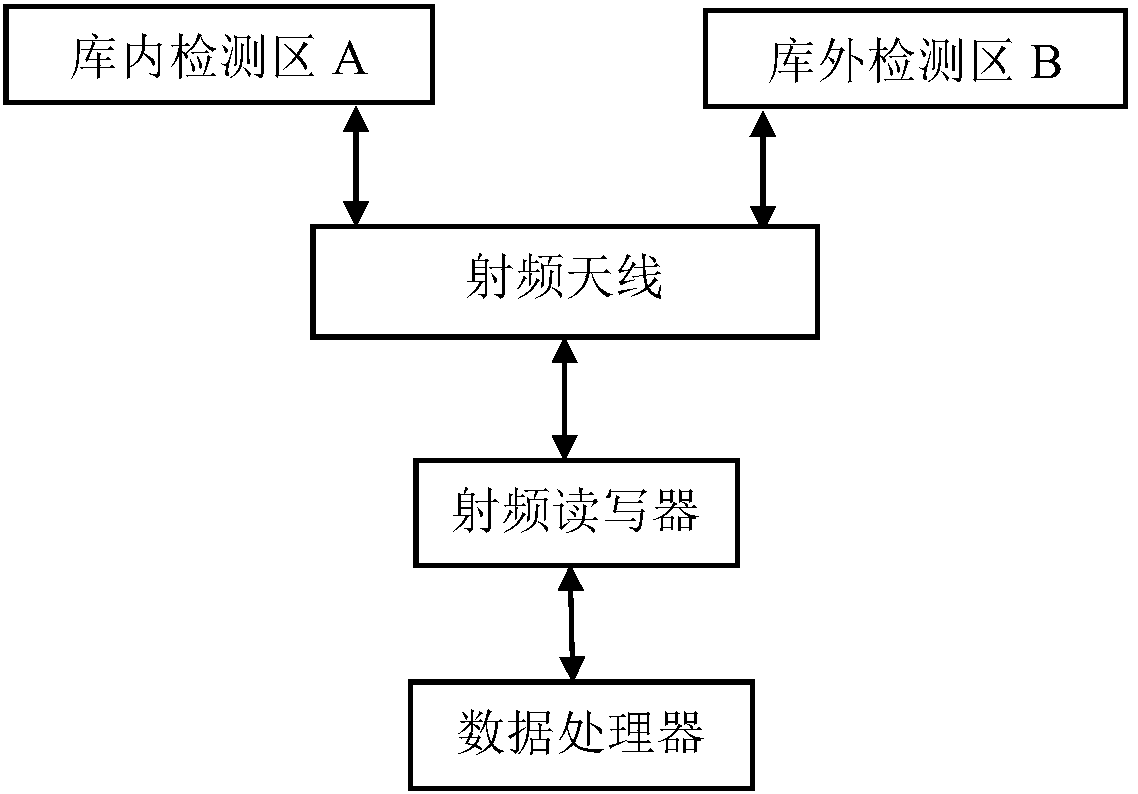

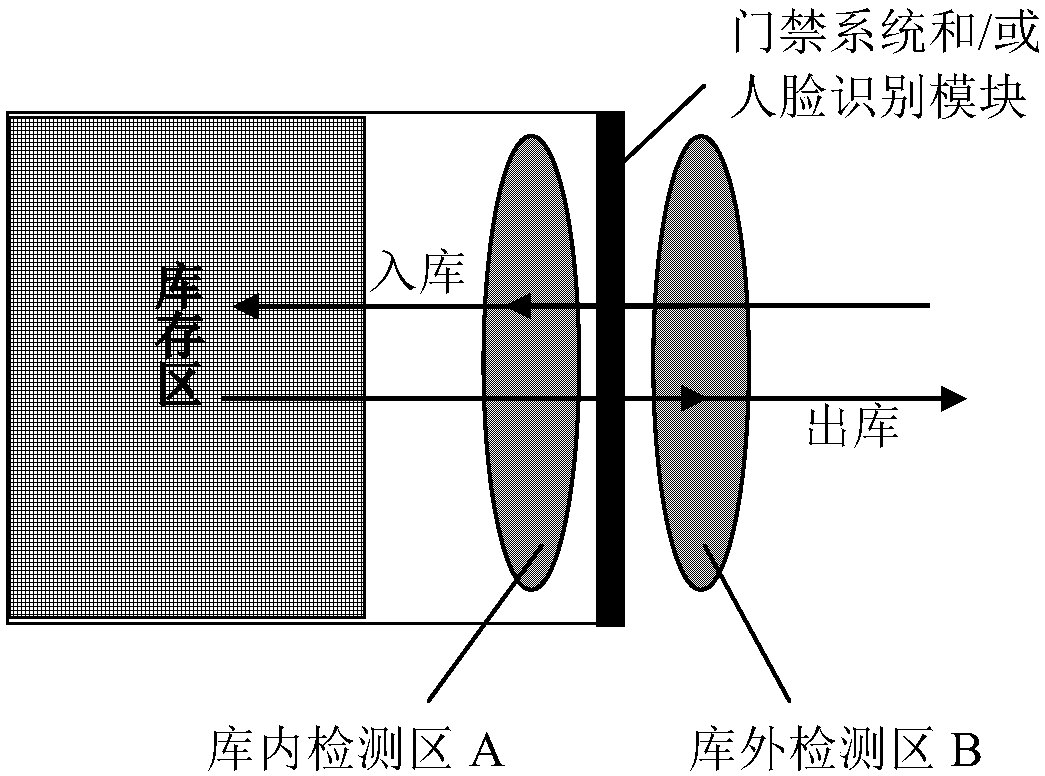

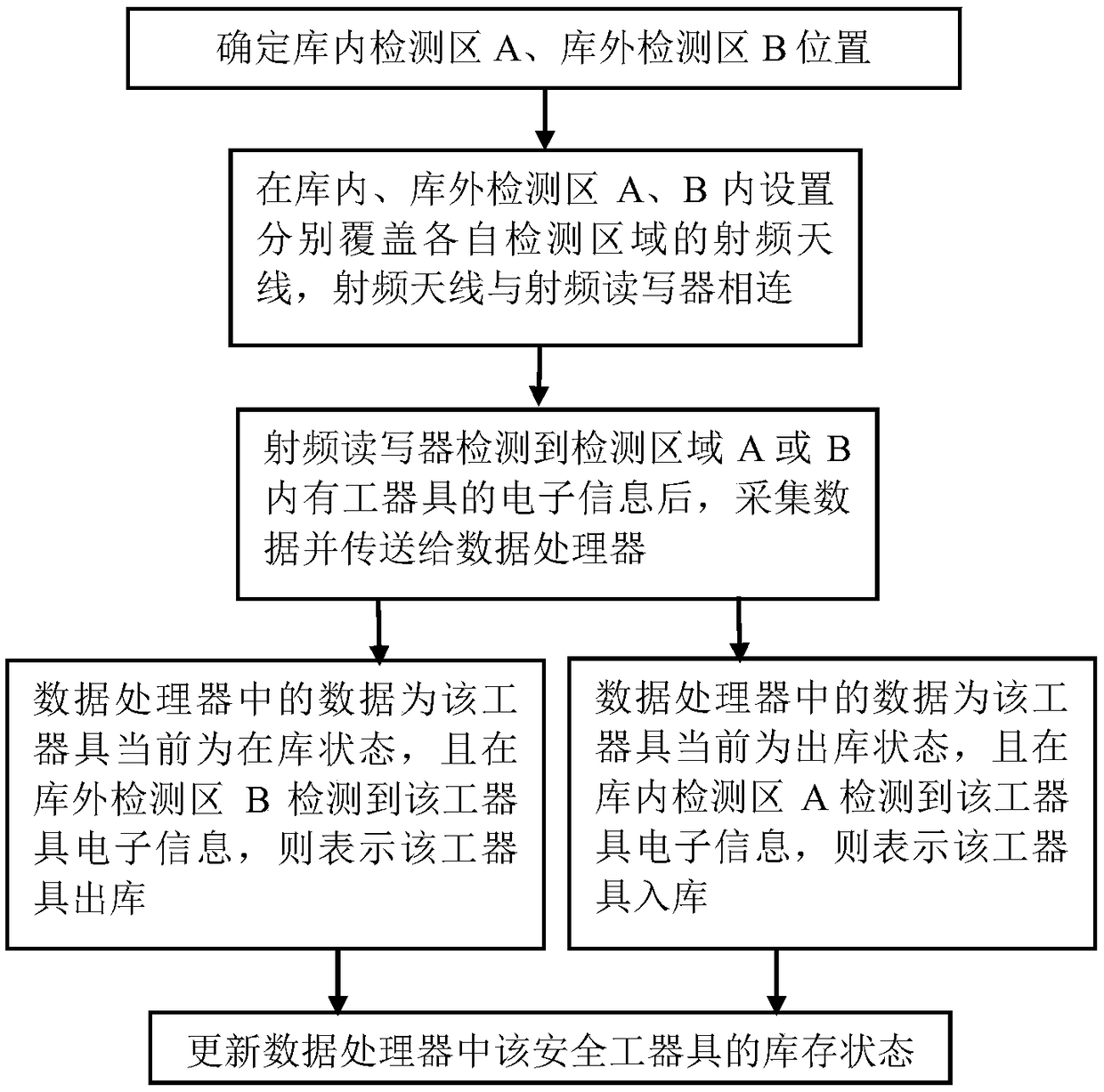

[0031] Such as figure 1 As shown, the hardware involved in the management method of tools entering and leaving the warehouse of the present invention includes the detection area A inside the warehouse and the detection area B outside the warehouse, which are respectively arranged on the necessary paths for the tools to enter and leave the warehouse, and are used to read the data set in the work area. The radio frequency reader of the radio frequency tag on the appliance, a number of radio frequency antennas arranged in different positions in the detection area A inside the library and the detection area B outside the library, and a data processor for data analysis. The radio frequency antenna is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com