Transformer capable of rapidly dissipating heat

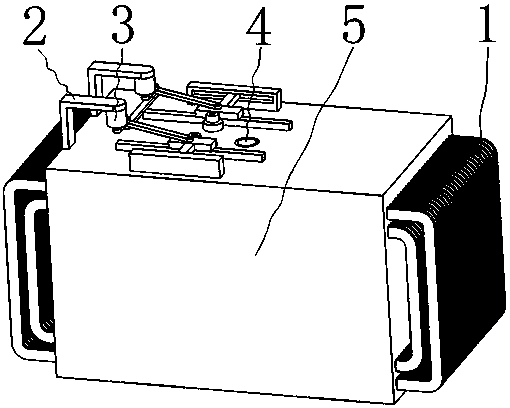

A technology for transformers and transformer coils, applied in the field of transformers, can solve problems such as large power consumption, energy waste, and temperature rise of coil windings, and achieve the effects of improving service life and accelerating heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

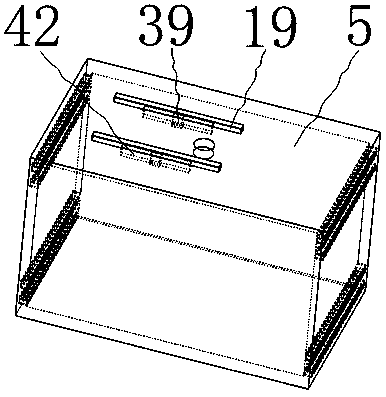

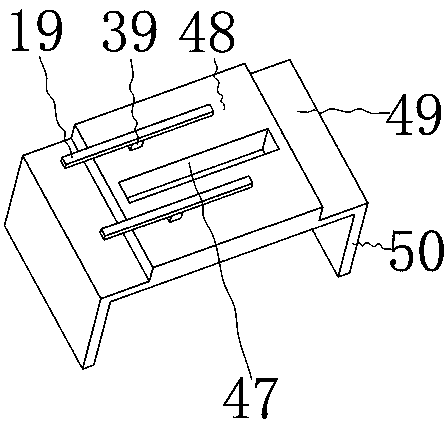

[0051] The specific embodiment: when using the transformer designed by the present invention, when the transformer is working, the drive motor 3 is controlled to work, and the drive motor 3 can drive the corresponding rocking bar 9 to rotate around the axis of the drive motor 3 output shaft through the output shaft; the rocking bar 9 The rotation drives the corresponding swing rod 11 to swing; because one side of the slider 12 is equipped with a guide rod 14; the guide rod 14 cooperates with the guide groove 20 opened on the guide support; the guide support block 13 is installed on the upper side of the installation shell 5; Therefore, the swing of the pendulum 11 will drive the corresponding slider 12 to slide; the sliding of the slider 12 will cause the corresponding fourth gear 25 to rotate; the rotation of the fourth gear 25 will drive the corresponding first shaft 23 to rotate; the rotation of the first shaft 23 will drive The corresponding third gear 24 rotates; the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com