Weak current cable connection control system

A technology for connecting control and electric cables, applied in the field of weak current cable connection control system, can solve the problems of inapplicable weak current box, inconvenient travel, small entry space, etc., to avoid heat accumulation, easy installation, and easy heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further detailed explanation through specific implementation mode below:

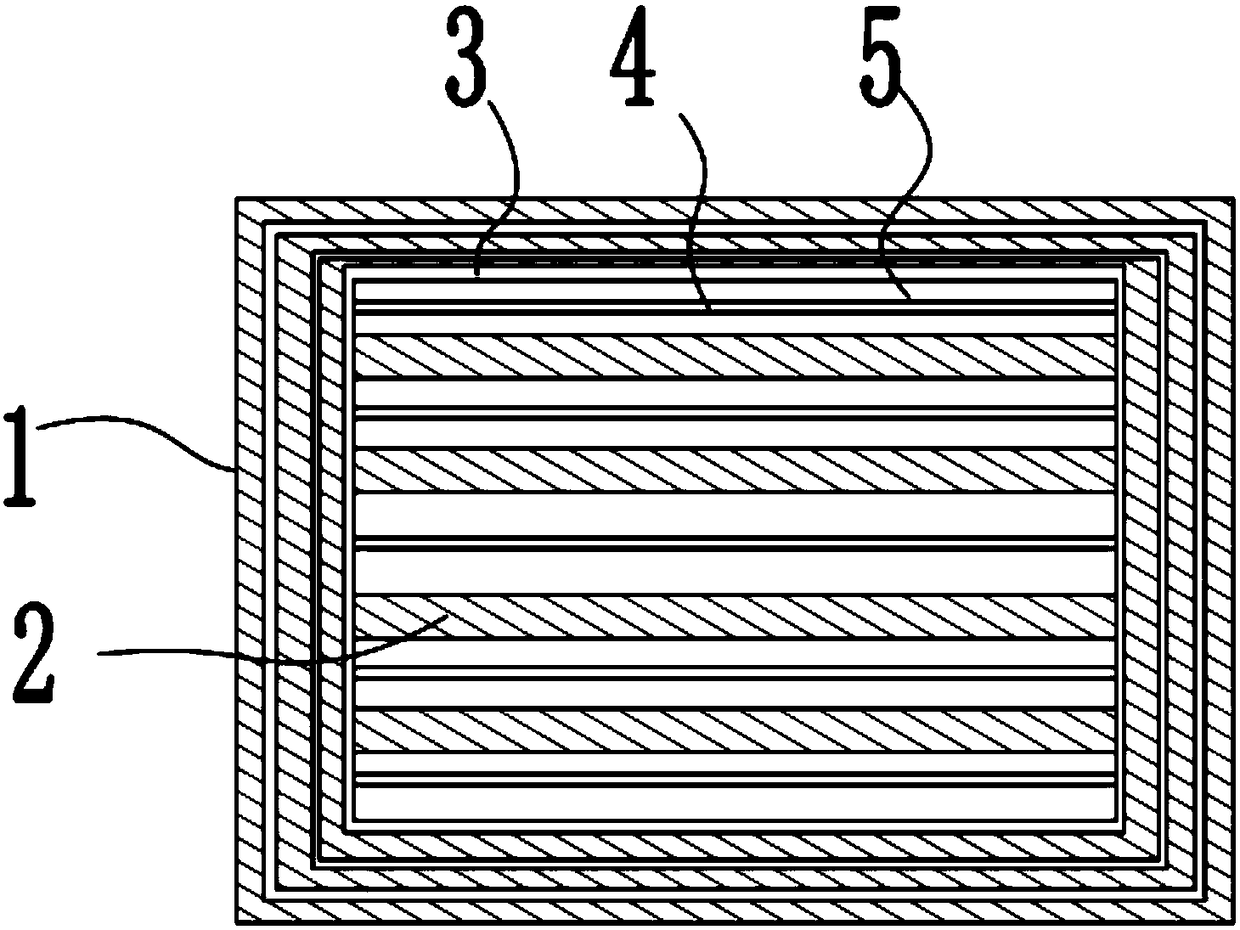

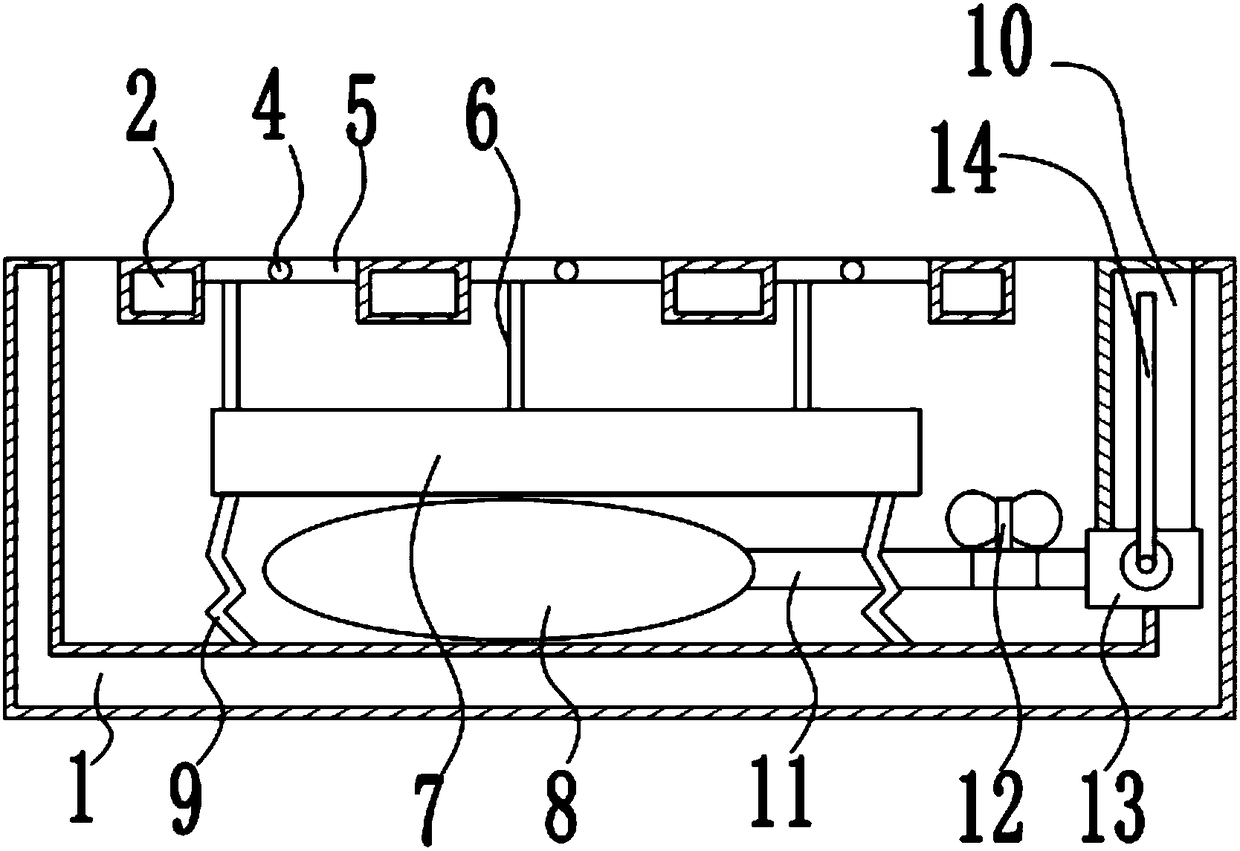

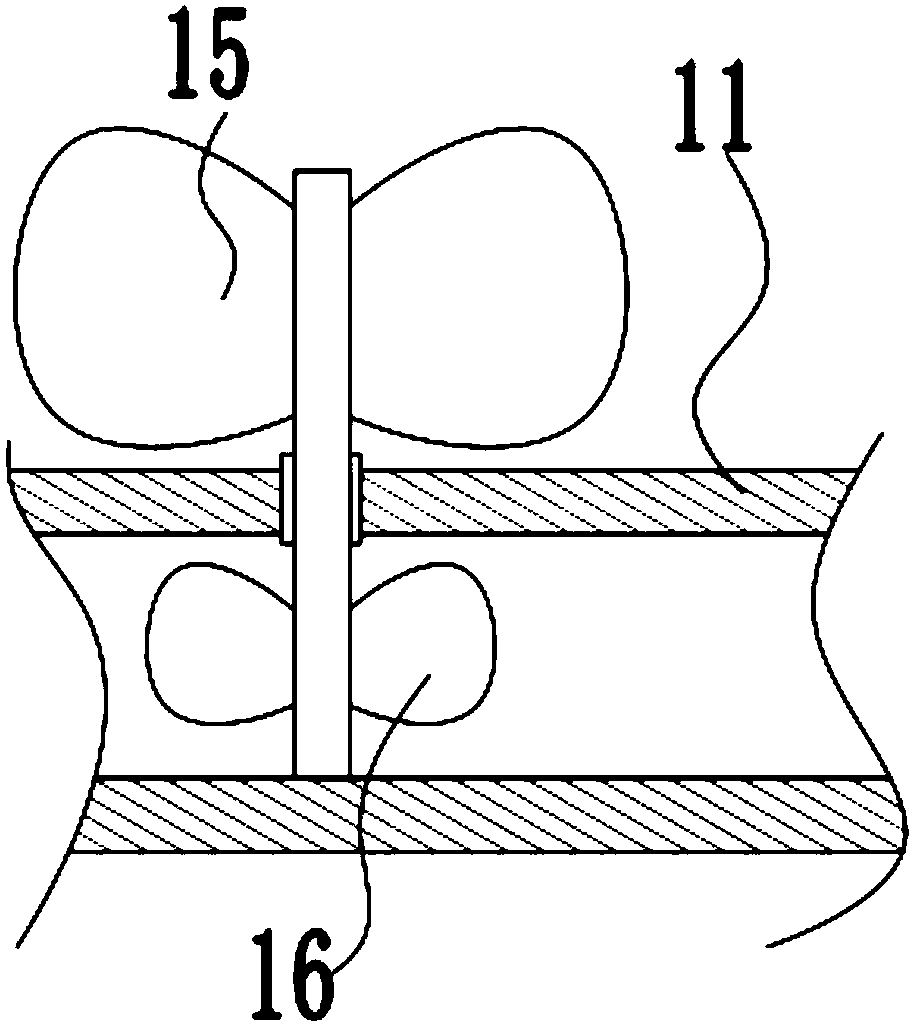

[0027] The reference signs in the drawings of the description include: installation frame 1, horizontal bar 2, deformation frame 3, strut 4, winding plate 5, connection belt 6, installation box 7, air bag 8, spring 9, cooling box 10, communication Pipe 11, fan 12, cylinder 13, rocking rod 14, outer fan 15, inner fan 16.

[0028] Such as figure 1 and figure 2 As shown, the weak current cable connection control system includes an installation frame 1 with a rectangular frame structure. The top frame of the installation frame 1 has a "mouth"-shaped opening, and the bottom plate, left side plate, and right side plate of the installation frame 1 are hollow. The flat plate structure also includes four horizontal bars 2 installed on the installation frame 1 at intervals, the hollows between the four horizontal bars 2 and the hollows between the four horizontal bars 2 and the installation frame 1, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com