Method for detecting defect coordinates on color filter

A color filter, defect coordinate technology, applied in the direction of optical testing defects/defects, etc., can solve the problems of inability to handle defects, many inspection steps, large defect coordinate errors, etc., to reduce the work cycle, accurate defect coordinates, and improve detection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

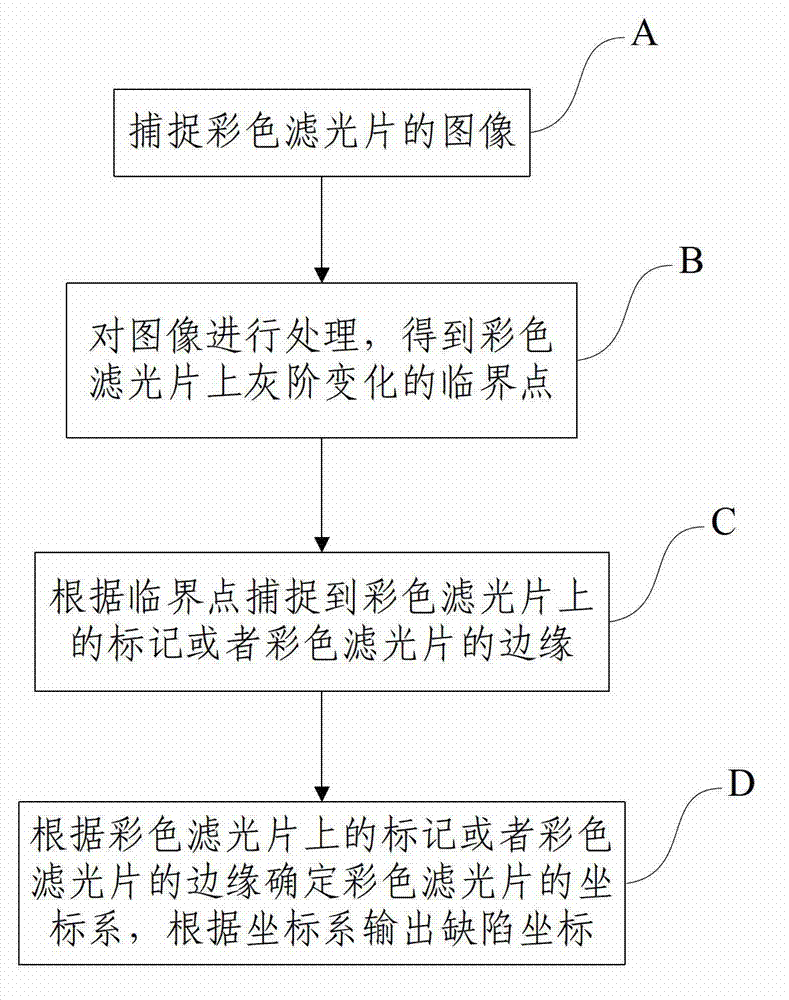

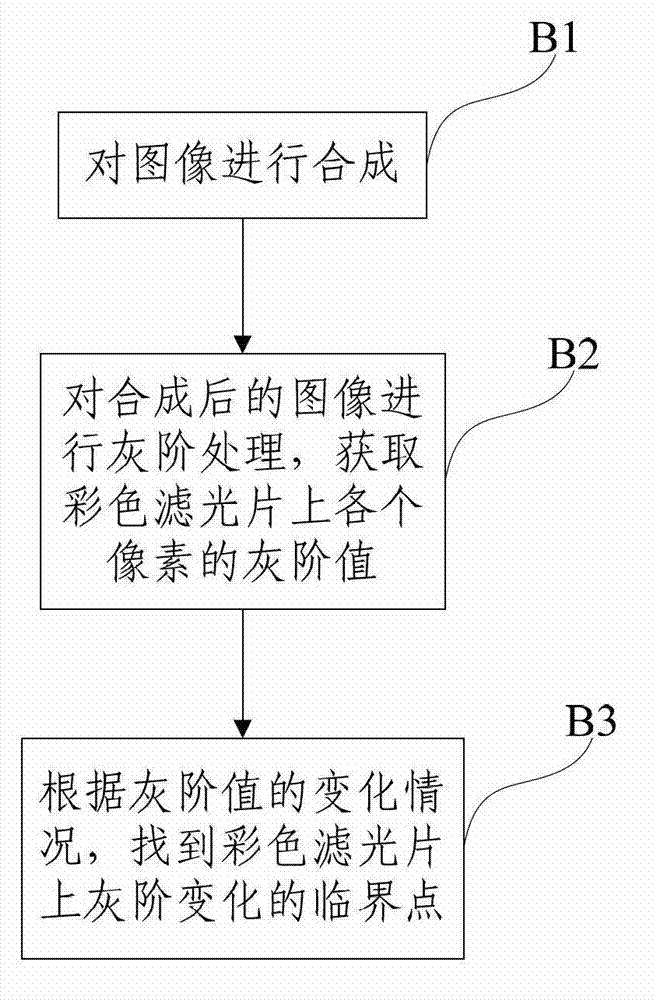

[0029] figure 2 It is a flow chart of the detection method of the defect coordinates on the color filter described in the embodiment of the present invention, as figure 2 As shown, the method comprises the steps of:

[0030] A: Capture the image of the color filter.

[0031] In this step, the image of the color filter is captured by a time-delay-integrated charge-coupled device (ie, TDI CCD), and the image has relatively high resolution. TDI CCD is suitable for imaging some high-speed moving objects. Its advantage is that the signal of multiple rows of linear array pixels is added and imaged for the same scene. Compared with ordinary linear array CCDs (especially area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com