Dual-function grommet

A grommet, dual-function technology, applied in the direction of electrical components, etc., can solve the problems of loose welding, the whole machine cannot work normally, and the fixed point of the end is subjected to large force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

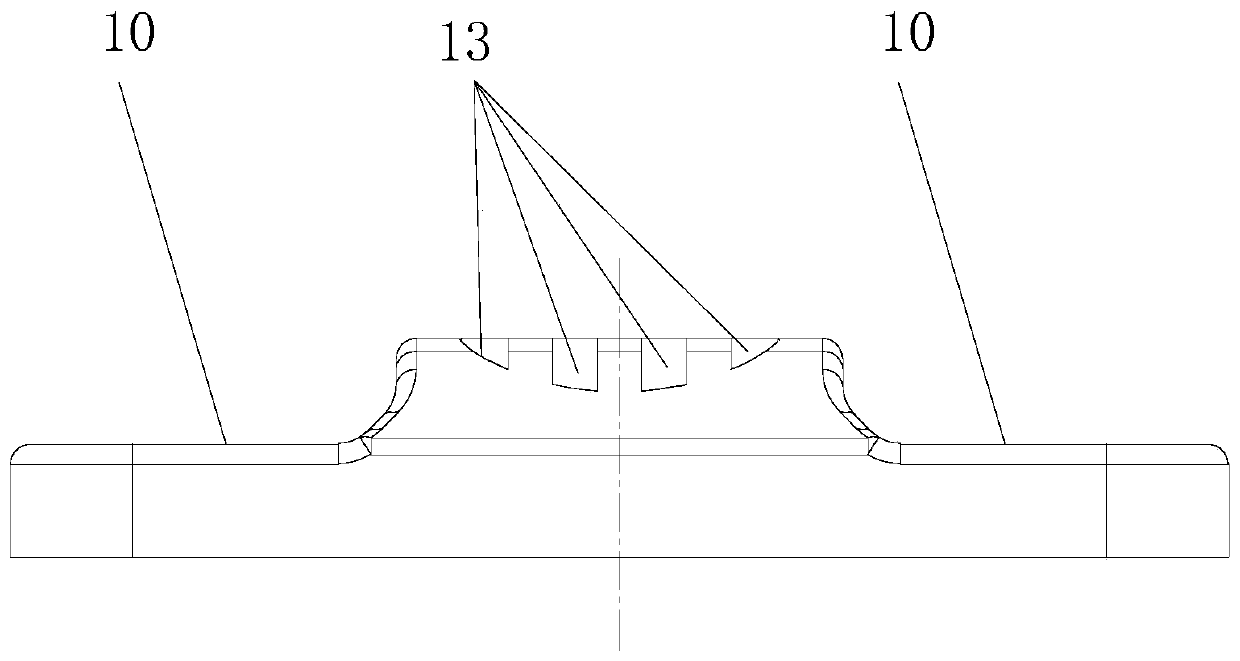

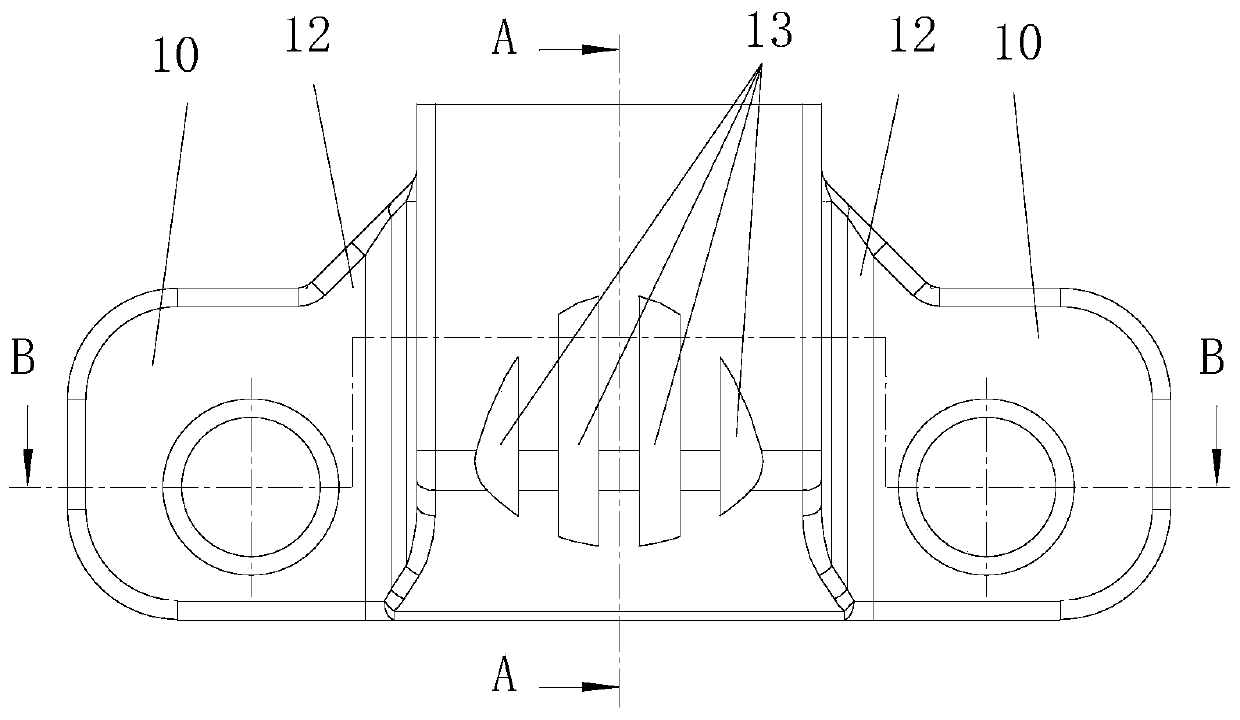

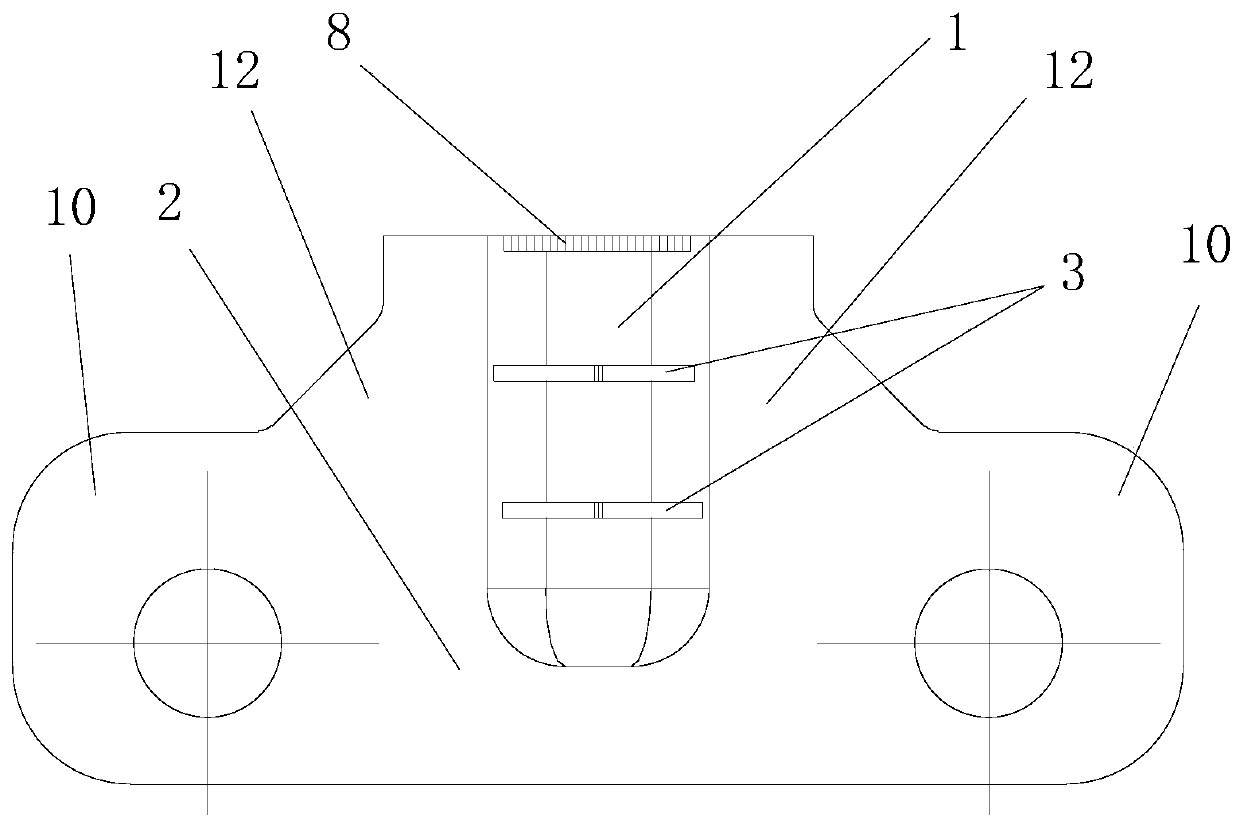

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The illustrated embodiment is a dual-function wire sheath. In the dual-function wire protection sleeve of this example, the fixed surface 2 is close to the surface where the perforation is located, and the middle part of the fixed surface is provided with a wire protection groove 1 along the vertical direction. A pair of fixing lugs 10 are arranged on both sides of the wire protection groove, and screw through holes 11 are provided through the thickness direction on the fixing ears, and the wire protection sleeve can be fixed at the perforation position by auxiliary materials such as screws and bolts. The connecting line of the centers of the two screw through holes is perpendicular to the length direction of the wire protection groove, so that the overall shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com